Propeller quick-release mechanism

A propeller and wing technology, which is applied in the field of the propeller mechanism of the plant protection drone, can solve the problems of difficult disassembly, damaged and replaced rotors, etc., and achieves the effect of meeting the flight needs, avoiding in-position and reasonable limit structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be further described,

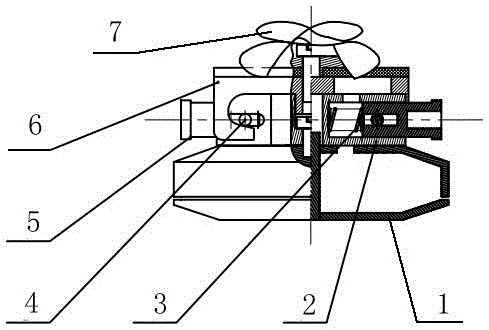

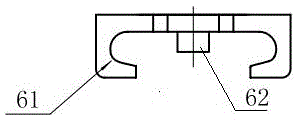

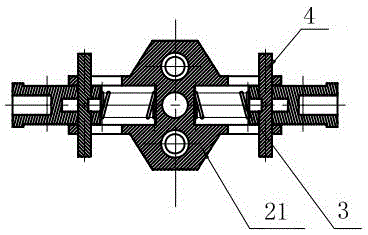

[0014] Such as Figure 1 to Figure 4 As shown, the present invention provides a quick-release mechanism for a propeller, which includes a motor 1 and a propeller 7 installed at the end of the aircraft wing, the propeller mount 6 is movably connected to the bottom of the propeller 7, and the propeller mount 6 is provided with an opening relative to the bottom of the propeller mount 6. Arc-shaped slot 61. And the utilization screw of motor 1 is fixed with cuboid motor mount 2, is provided with the pressing shaft 5 of telescopic connection along the both sides of length direction, is respectively provided with bearing pin 4 on the horizontal direction perpendicular to pressing shaft 5, bearing pin 4 The inner spring 3 moves with the expansion and contraction of the pressing shaft 5. The groove 61 of the propeller mounting base 6 is provided with a groove suitable for the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com