Sectionalized bottle-blocking pressure-relieving device in container conveying mechanism

A technology of conveying mechanism and pressure relief device, which is applied in the direction of packaging bottles, packaging, transportation and packaging, etc., can solve the problems of deformation, extrusion and deformation of solid bottles, so as to improve packing efficiency, avoid extrusion deformation, reduce The effect of squeeze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

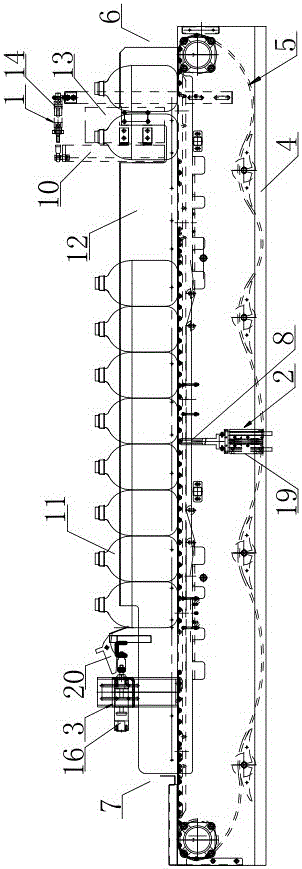

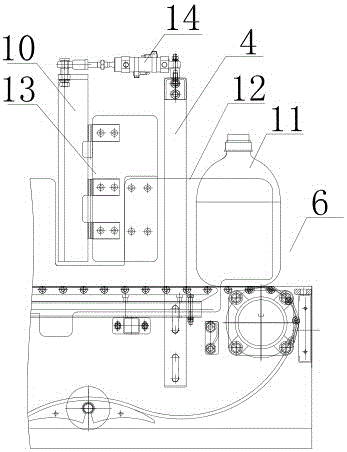

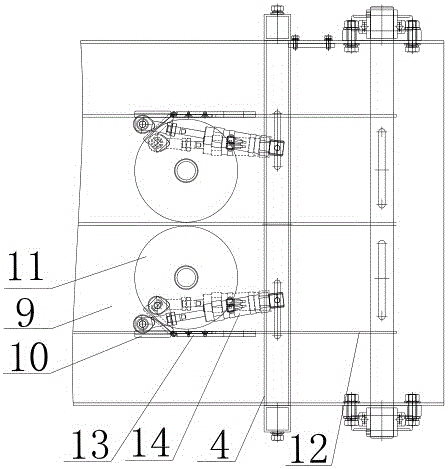

[0019] Such as figure 1 , figure 2 , image 3 As shown, the segmented bottle-stopping and pressure-relief device in the packing conveying mechanism includes: a frame 4, on which a first bottle-stopping mechanism 1, a second bottle-stopping mechanism 2, and a third bottle-stopping mechanism 3 are arranged. . The first bottle retaining mechanism 1 is located at the upper bottle end 6 of the conveying channel in the packing conveying mechanism 5. The first bottle retaining mechanism 1 includes some bottle retaining doors 10 corresponding to the conveying passage 9, and each bottle retaining door 10 can Rotate to block in the corresponding conveying passage 9, thereby blocking the passage of the solid bottle 11 in the conveying passage 9, and each bottle stop door 10 can also be rotated to be positioned at the side of the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com