Spiral rebar connector

A technology of spiral steel bars and connectors, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of inability to fully utilize the mechanical properties of materials, unfavorable seismic performance of prefabricated structures, and uncoordinated concrete deformation, and achieve deformation coordination. , low cost and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

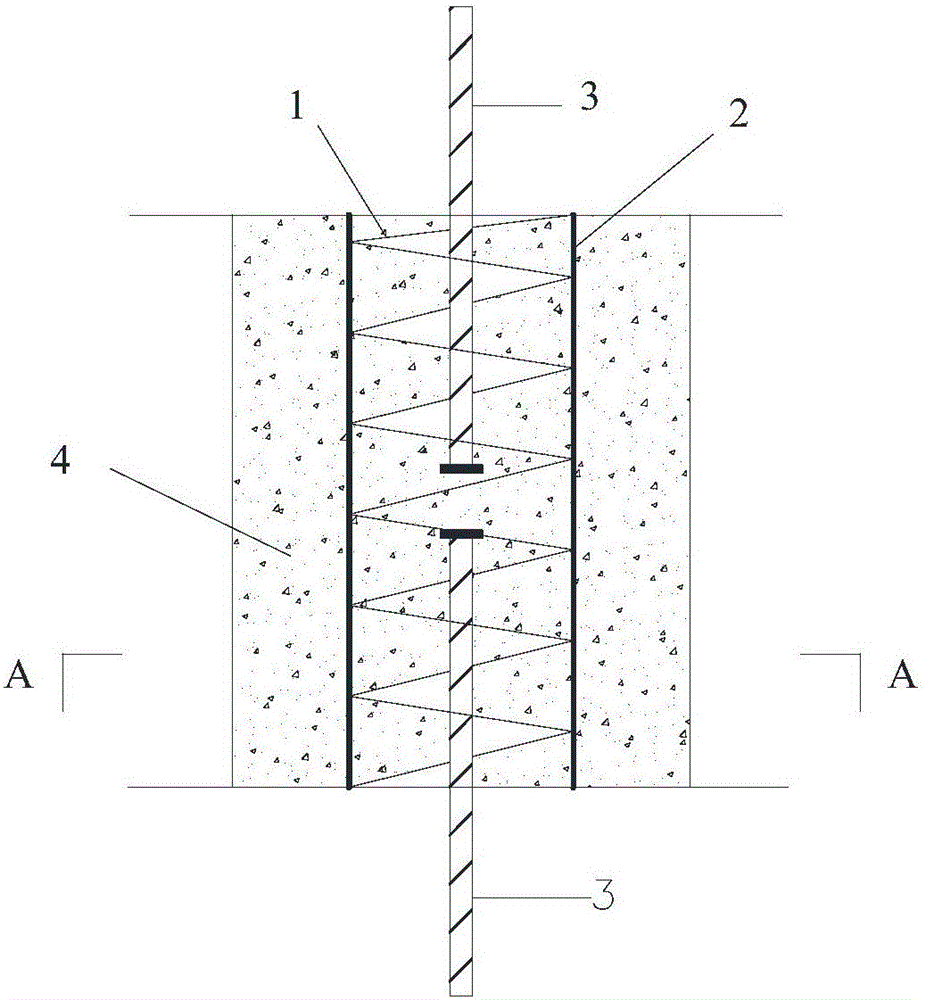

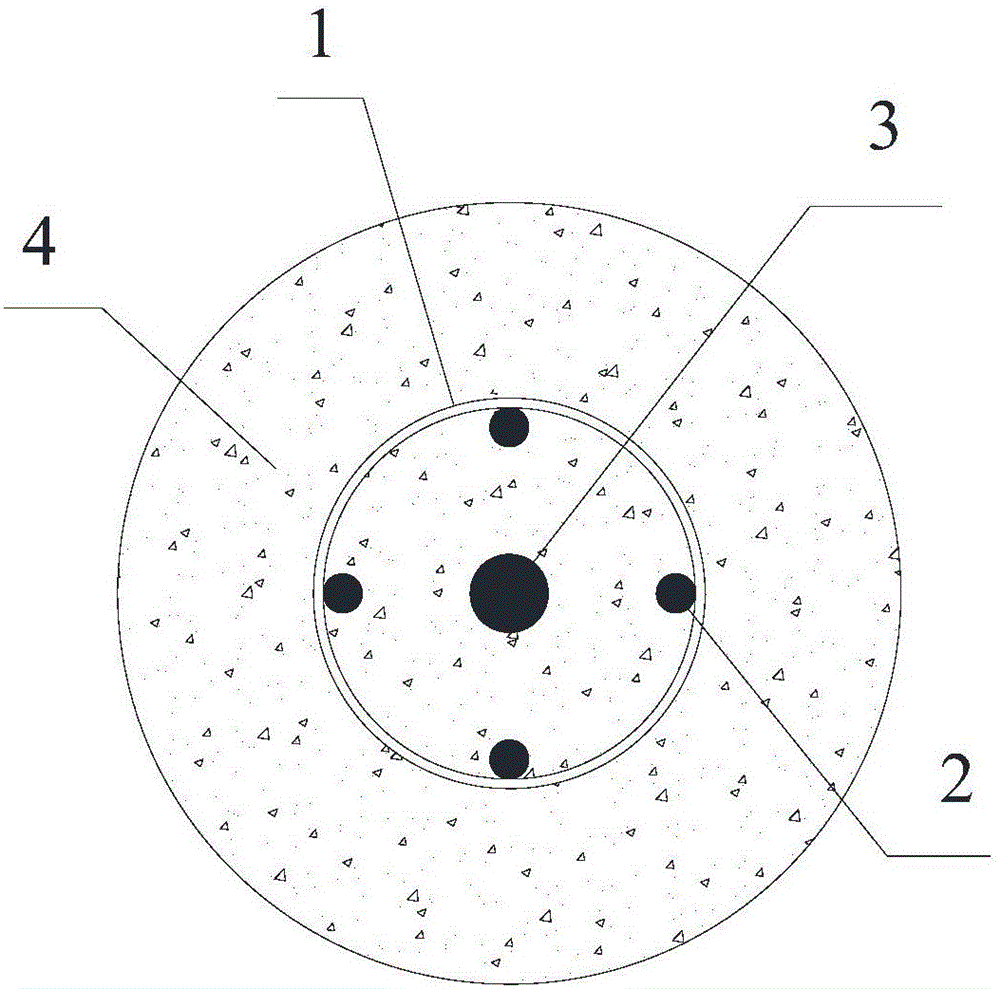

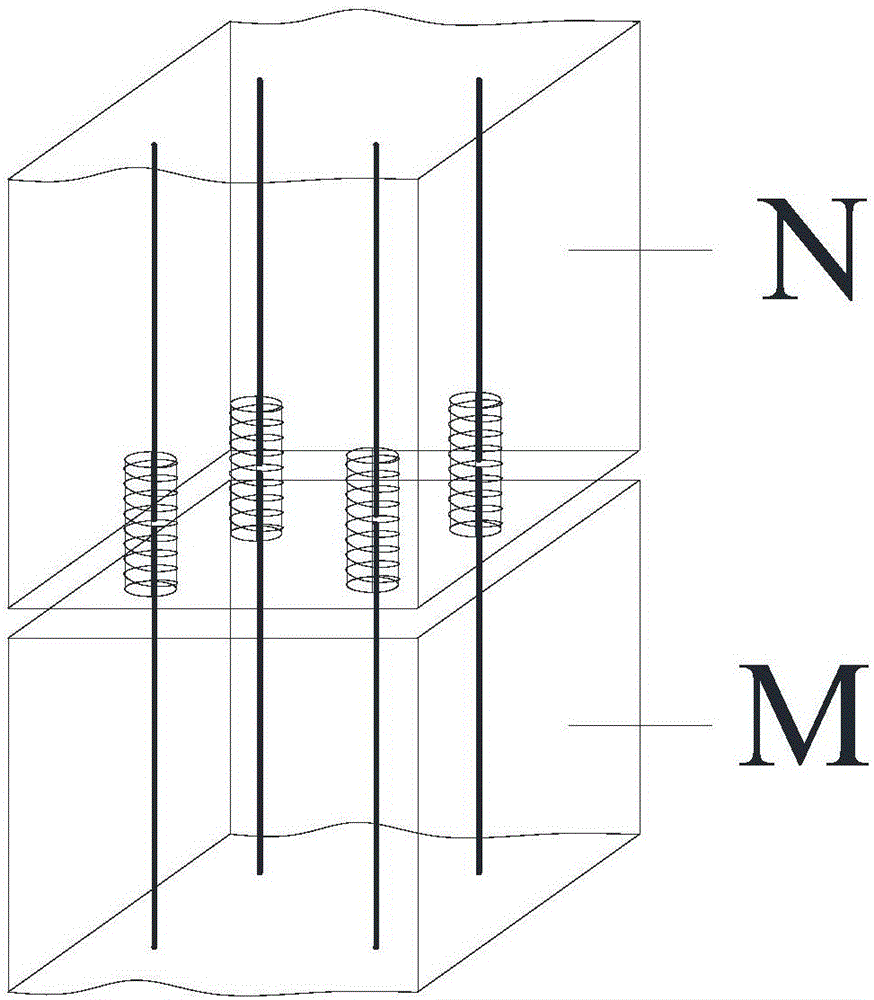

[0014] When the building structure needs to connect steel bars between components, the spiral steel bar connector of the present invention can be used to achieve the mechanical properties not lower than the direct connection of steel bars. The present invention can not only be used in the design and construction of new buildings, but also in the seismic reinforcement of existing buildings, such as Figure 1-Figure 3 As shown, among them, figure 1 It is a structural schematic diagram of a spiral steel bar connector according to the present invention, figure 2 for figure 1 The A-A section diagram, image 3 It is a schematic diagram of the application of the present invention; it specifically includes: 1—spiral steel bar, 2—lapped steel bar, 3—connected steel bar, 4—grouting material, M—lower prefabricated component, N—upper prefabricated component.

[0015] Among them, the spiral steel bar can fix no less than one lapped steel bar, and a larger number of lapped steel bars ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com