Condenser for acid steam

A condenser, acid vapor technology, applied in the direction of heat exchanger type, indirect heat exchanger, fixed tubular conduit components, etc., can solve the problems of cooling loss, increased energy consumption, increased process load, etc., to increase the system load , Efficient condensation, avoid the effect of re-absorbing acid vapor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

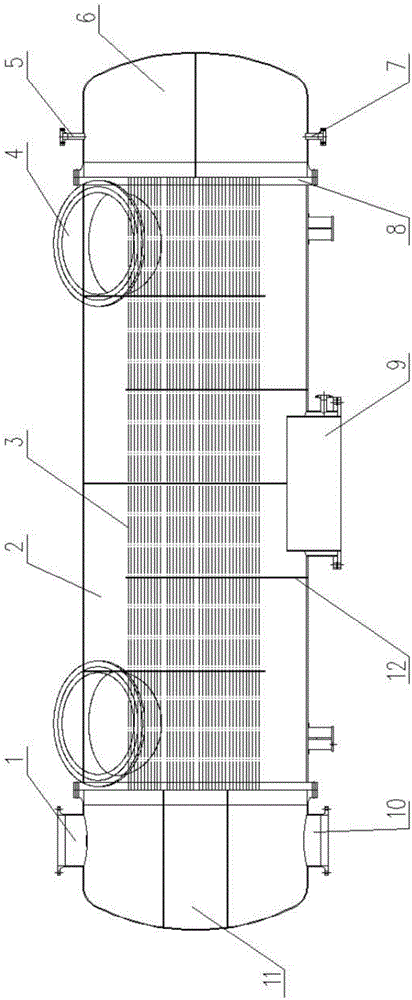

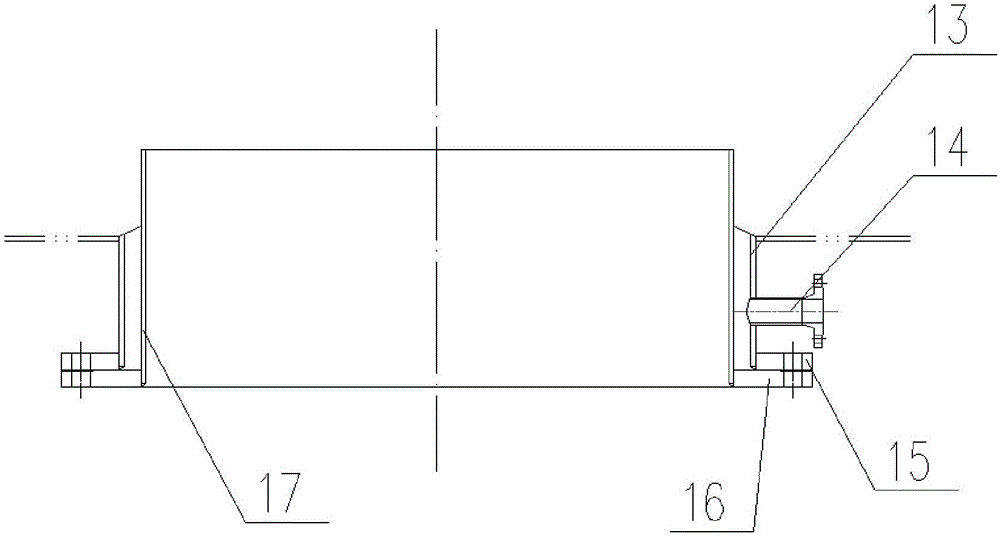

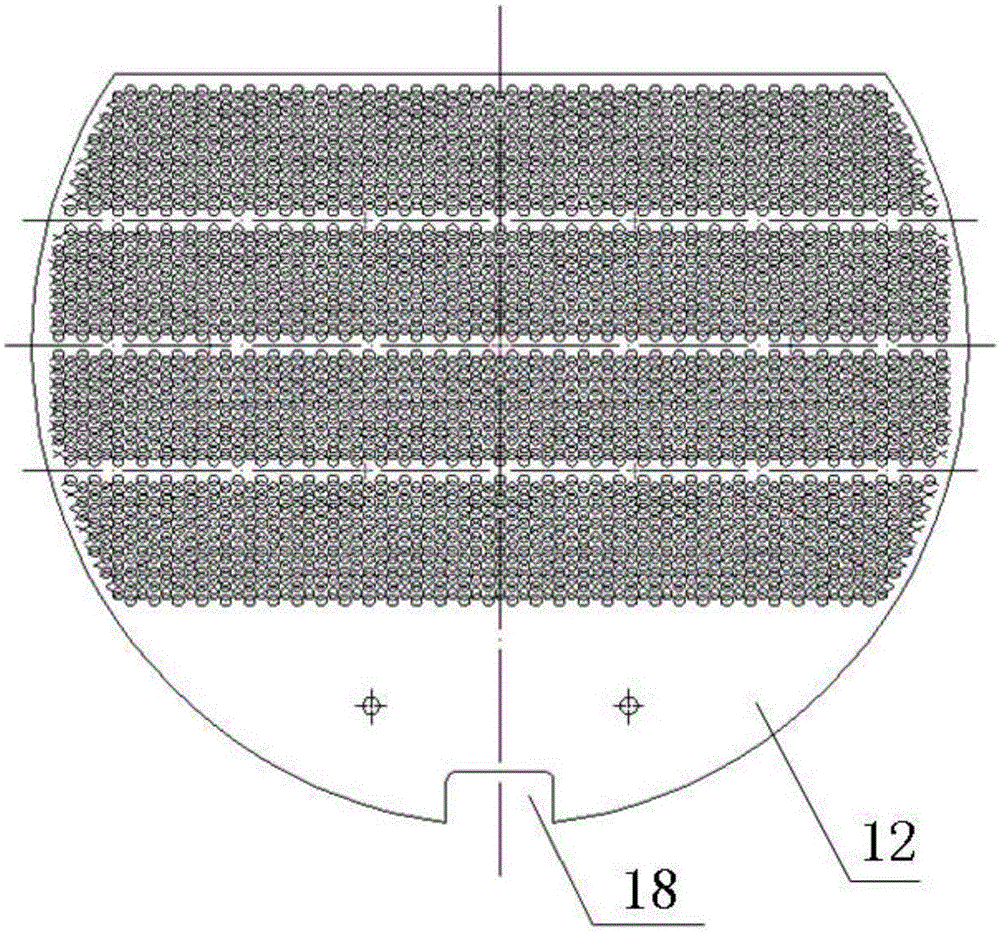

[0014] See Figure 1-Figure 3 , the sour vapor condenser is a fixed tube-sheet 8-type heat exchanger, which adopts a single-shell-pass multi-tube-pass structure, including shell 2, left-end tube box 11, right-end tube box 6, heat exchange tube 3, tube sheet 8, baffle Plate 12, acid vapor inlet 4, acid vapor outlet 9, cooling water inlet 10 and cooling water outlet 1. The upper part of the shell 2 is provided with an acid vapor inlet 4, the center of the lower part of the shell 2 is provided with an acid vapor outlet 9, the left pipe box 11 is provided with a cooling water inlet 10 and a cooling water outlet 1, and the right pipe box 6 is provided with a vent 5 and a vent 7 . A liquid discharge port 18 is provided at the bottom of the baffle pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com