An Elastic Blade Type Ultrasonic Motor Running in Two Directions

A technology of ultrasonic motors and elastic blades, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve problems such as the complexity of the motor structure design process, and achieve simple structure, The effect of avoiding wear and tear and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

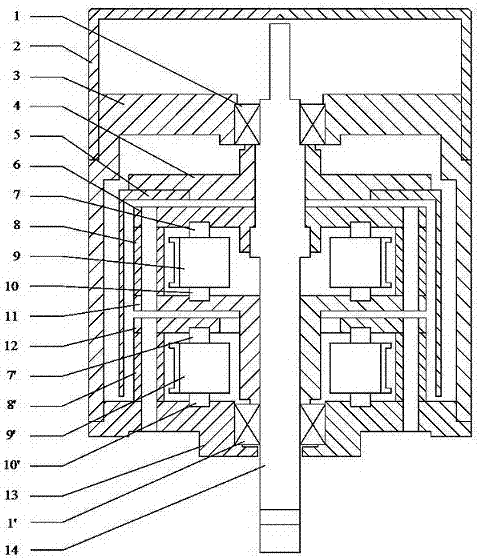

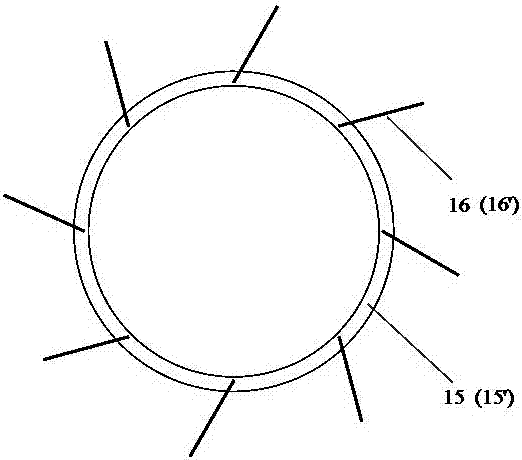

[0022] An elastic vane type ultrasonic motor operating in both directions, such as figure 1 As shown, it includes an end cover 2, a housing 3, a base 13, a rotor 5, a first stator, a second stator and a rotating shaft 14; the shape of the rotor 5 is cylindrical, and the stator is arranged in the rotor 5; The first stator is fixedly bonded to the rotating shaft 14 through the second connecting plate 6, and the second stator is installed on the base 13; the stator includes piezoelectric ceramics and metal rings, and several elastic blades are evenly fixed on the The outer surface of the metal ring is arranged on the inner surface of the rotor 5 and rigidly connected with the rotor, and the angle between the normal line of the fixed point where the elastic blade is installed on the outer surface of the metal ring and the elastic blade is 25-35 degrees At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com