Coupled Mode Ultrasonic Motor Based on Anisotropic Eccentric Constraint and Barotropic Electroceramics

An ultrasonic motor, piezoelectric ceramic technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of complex structure design, achieve compact motor structure, Compact, simple design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

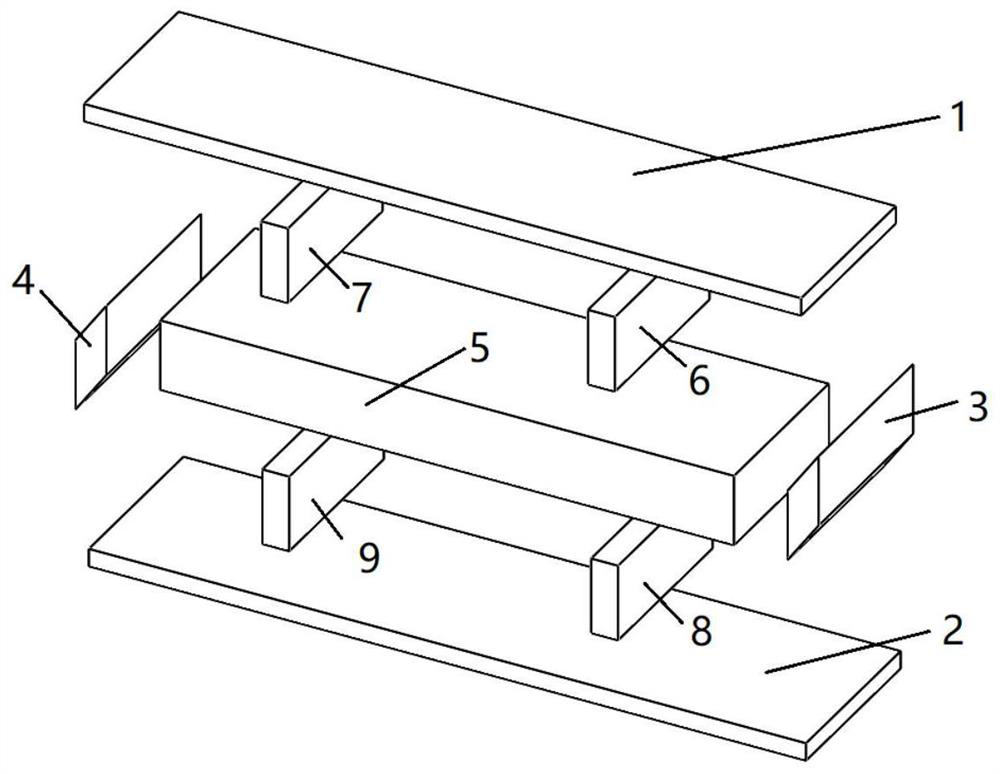

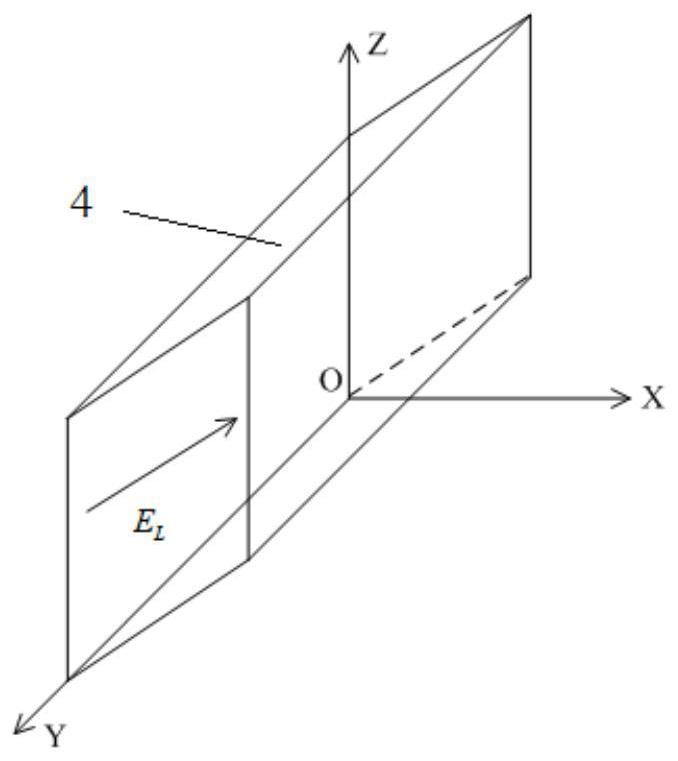

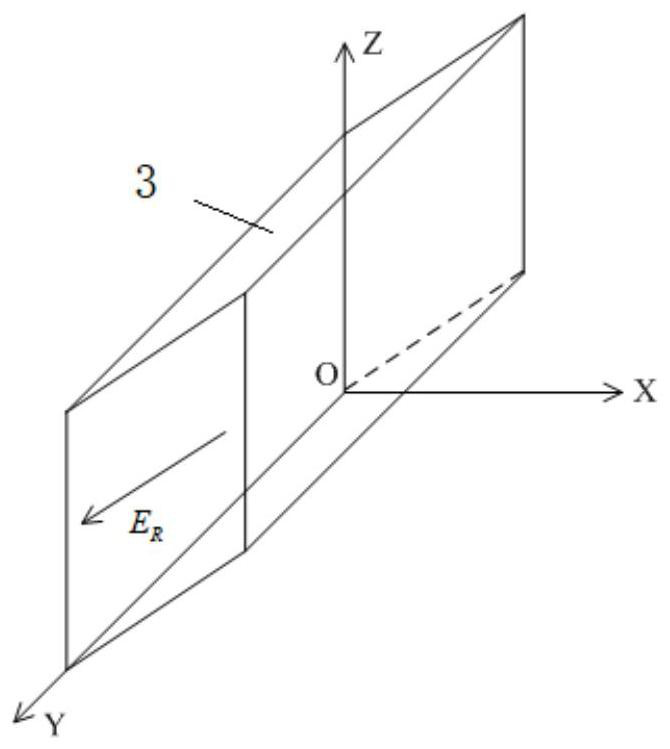

[0027] A coupled-mode ultrasonic motor based on anisotropic eccentric constraints and barotropic electroceramics, such as figure 1 , including a stator unit and a mover unit. The mover unit includes an upper mover 1 and a lower mover 2. The upper mover 1 and the lower mover 2 are respectively arranged on both sides of the stator unit. The stator unit includes a metal elastic body 5, an end Internal oblique piezoelectric ceramics, left upper driving foot 7, right upper driving foot 6, left lower driving foot 9 and right lower driving foot 8, end oblique piezoelectric ceramics include left end oblique piezoelectric ceramics 4 and right end oblique piezoelectric ceramics 3, metal elastic The two ends of the body 5 are respectively provided with a left-end oblique piezoelectric ceramic 4 and a right-end oblique piezoelectric ceramic 3; There is an upper left driving foot 7 and an upper right driving foot 6. The lower side of the metal elastic body 5 is provided with a lower left d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com