Novel edge pressing machine

An edge blanking machine and a new type of technology, applied in the chemical industry, can solve the problems of non-reuse, slow production speed, time-consuming consumables, etc., and achieve the effects of easy promotion, high processing efficiency and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

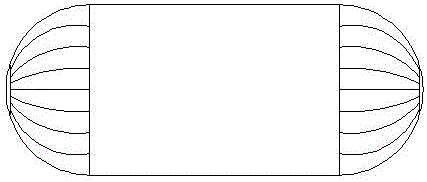

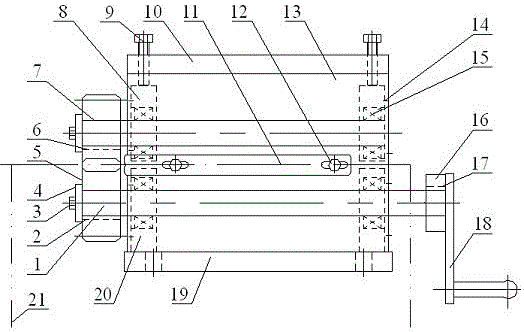

[0026] Such as figure 2 , 3 Shown, a kind of novel edge press machine, it comprises the upper cover plate 10 that is placed on the platform 21 that is connected together, a pair of side plates 13 and bottom plate 20 and the fixed bearing seat 19 that places a pair of side plates 13 inner sides and Floating bearing seat 8.

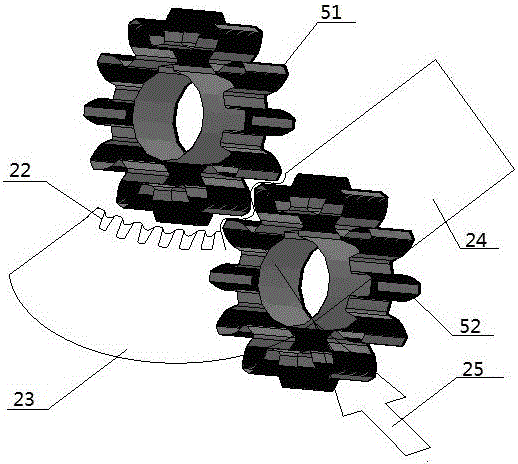

[0027] The upper end of a pair of side plates 13 is provided with an upper cover plate 10, and its lower end is provided with a bottom plate 20, and its inner side is provided with a groove; the middle part of one side plate 13 is provided with two threaded holes, and set screws 12 are arranged in the two threaded holes; The positioning screw 12 fixes the positioning guide ruler 11 with two elongated holes; the driving shaft 1 connected with the motor is arranged in the fixed bearing seat 19; the driven shaft 7 is arranged in the floating bearing seat 8, and the adjusting bolt 9 is arranged on the top thereof ; The fixed bearing seat 19 and the floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com