Machining method for proteiform double-side-cavity square long rod part

A processing method and technology for long rods, which are applied in the inner cavity machining of easily deformable square long rods and thin-walled parts, and in the field of easily deformable square long rods, so as to improve the qualification rate, improve processing efficiency and product qualification. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

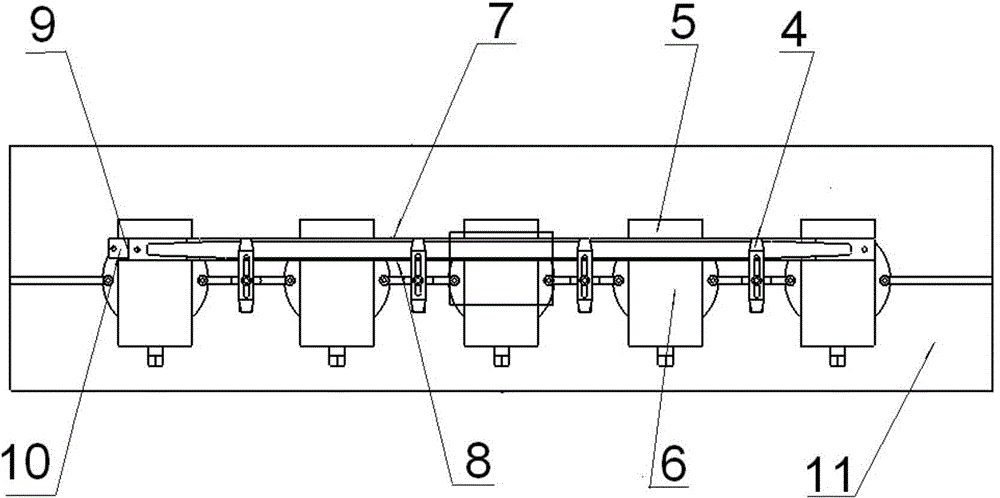

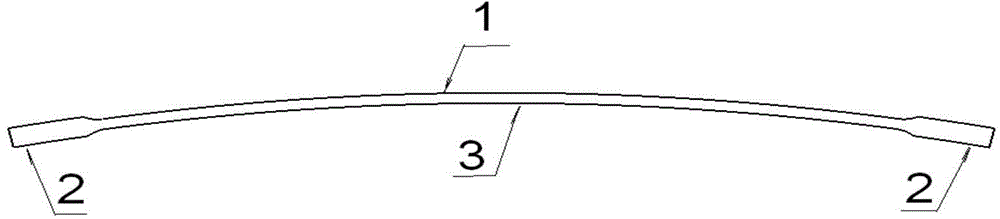

[0022] Refer below figure 1 and figure 2 , the present invention will be further described in detail through specific examples.

[0023] First, fix a group of vises on the machine tool to level the horizontal positioning surface of the vise, align the vise to fix the jaw 5, and press the vise chassis with bolts to make it positioned with the machine tool; The side increases longitudinal reference positioning block 10 in order to longitudinally locate parts, and then the easily deformable double-sided cavity square long rod member that has milled the hexagonal rough reference is positioned and tightened in this group of vices. Flatten and press the parts with the pressure plate from left to right in turn, so that the bottom surface of the part fits perfectly with the horizontal positioning surface of the vise; the clamping force of the active jaws of the vise makes one side 7 of the part fit completely with the fixed jaw 5 of the vise Clamp the part completely. The position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com