A Shearing Device Convenient for Remote Maintenance

A shearing device, long-distance technology, applied in the direction of shearing device, shearing machine equipment, metal processing equipment, etc., can solve the operation distance, range, means, degree of freedom and flexibility limitations, and equipment cannot be disassembled and replaced. , difficulties in maintenance work, etc., to achieve the effect of reducing radioactive dose, improving maintenance efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

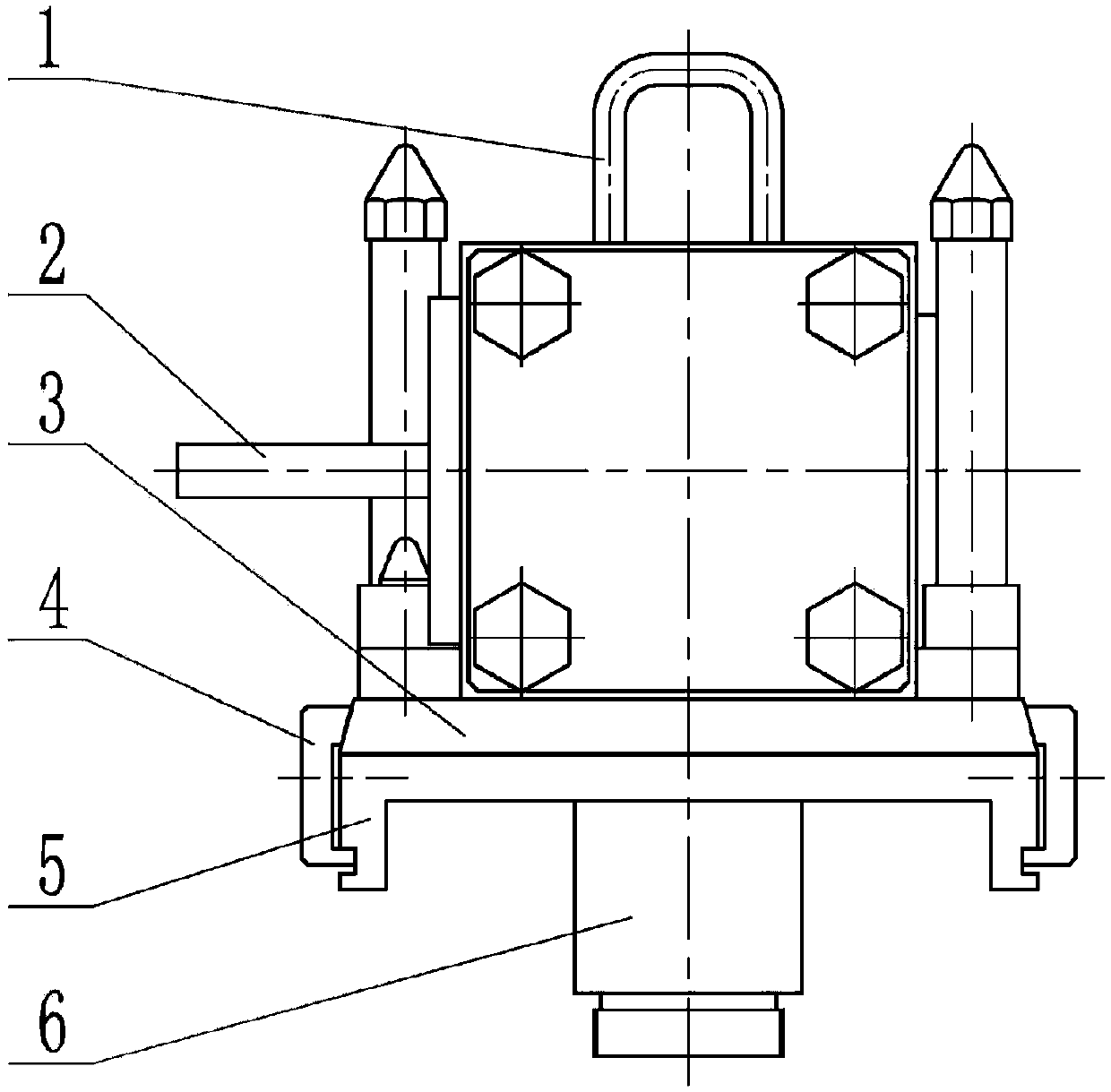

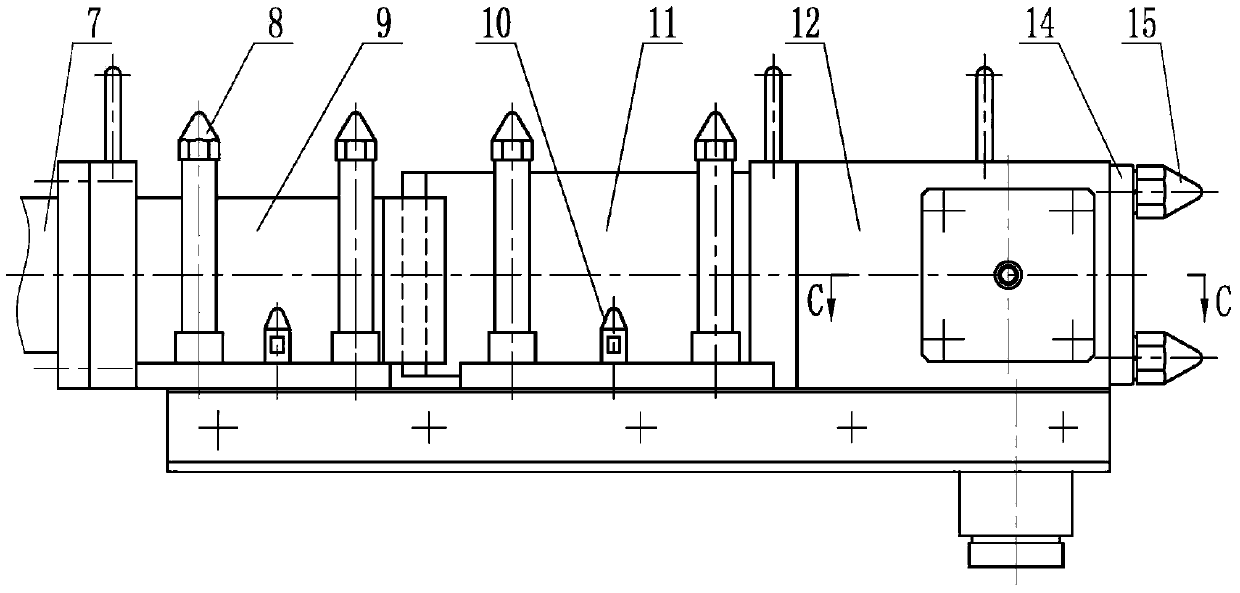

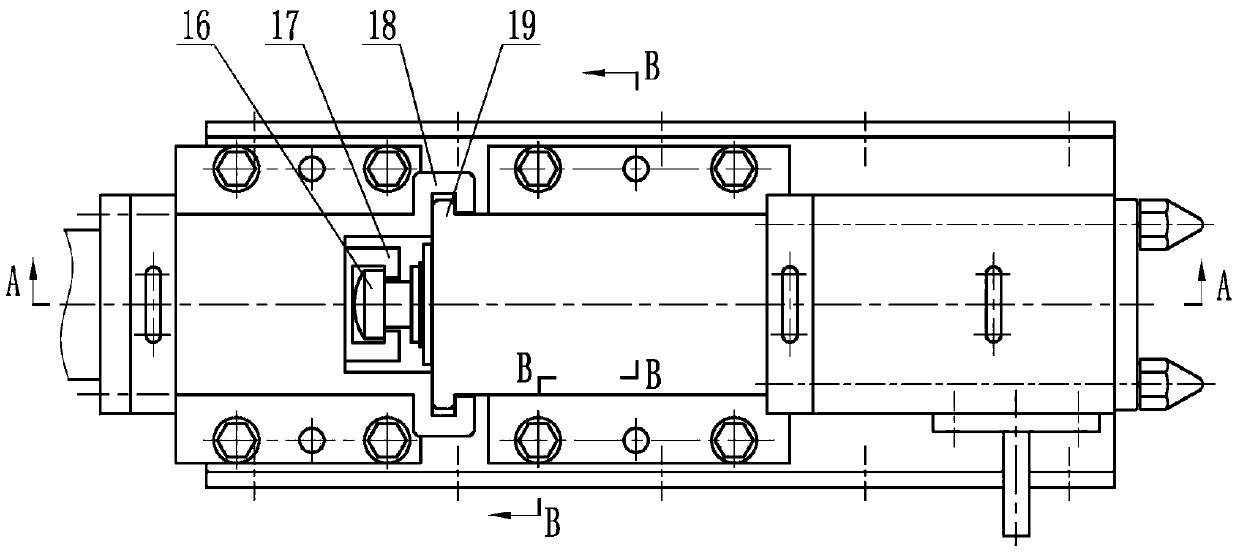

[0035] Such as figure 1 , figure 2 As shown, the present invention is made up of three overhaul modules, fixed part and table top 5.

[0036] Among them, the fixed part is composed of the bottom plate 3, the blanking port 6, the positioning pin 10, the pressure plate 4 and its cone head screw, the blanking port 6 and the positioning pin 10 are fixed on the bottom plate 3, and the bottom plate 3 passes through the pressure plate 4 and its cone head. Screws are fixed on the table top 5 .

[0037] Among them, the three maintenance modules are respectively the drive module, the cutter body module and the shear chamber module.

[0038] The connection and fixing relationship between the three maintenance modules and between each of them and the bottom plate 3 is as follows:

[0039] 1) The drive module is fixed on the bottom plate 3 by its correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com