Clamp for grinding of external spherical surface of spherical surface washer

A spherical gasket and outer spherical technology, applied in spherical grinder, grinding workpiece support, grinding/polishing equipment, etc., can solve the problem of insufficient clamping force of spherical gasket, easy to throw out of spherical gasket, and no way to use grinding Machining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

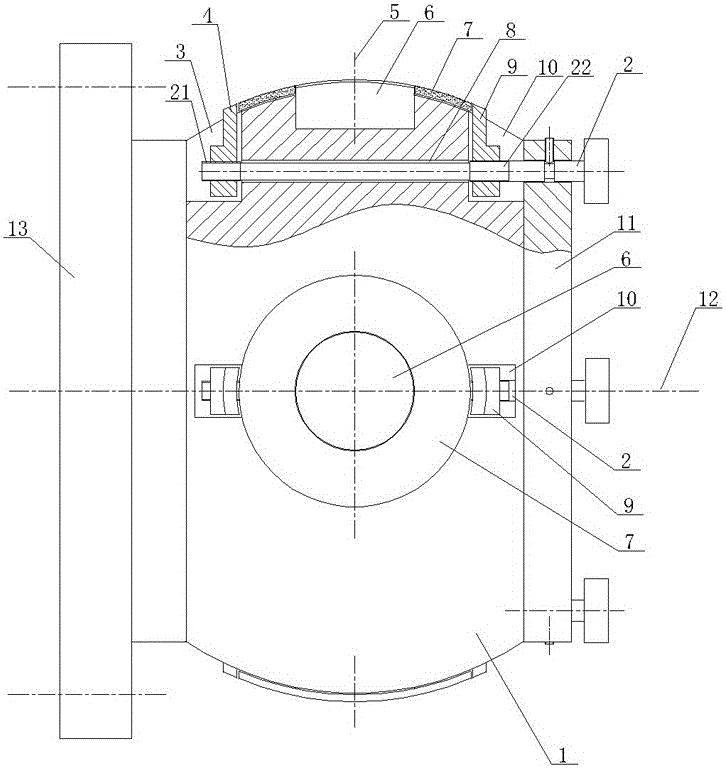

[0010] As shown in the figure, the spherical gasket outer spherical surface grinding fixture of the present invention includes a fixedly connected flange 13 and a chuck 1, the chuck 1 has a spherical arc surface with the same curvature as the inner spherical surface of the spherical gasket 7, and the chuck 1 The spherical arc is provided with four positioning pins 6 (the number of positioning pins can be arranged according to the actual situation). The axis 5 of the positioning pins 6 passes through the center of the spherical surface of the chuck 1 and is perpendicular to the rotation axis 12 of the fixture. The outer diameter of the positioning pins 6 Matching the diameter of the inner hole of the spherical gasket 7, the left clamping block 4 and the right clamping block 9 are arranged on both sides of the positioning pin 6, and the spherical arc surface of the chuck 1 is provided with a left concave cavity 3 corresponding to the left and right clamping blocks. The right cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com