Ink jet recording apparatus

A technology for inkjet recording and recording information, which is applied in printing and other directions, and can solve problems such as the inability to reduce the splitting distance of liquid jets, the inability to print with liquid droplets, and the increase in deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

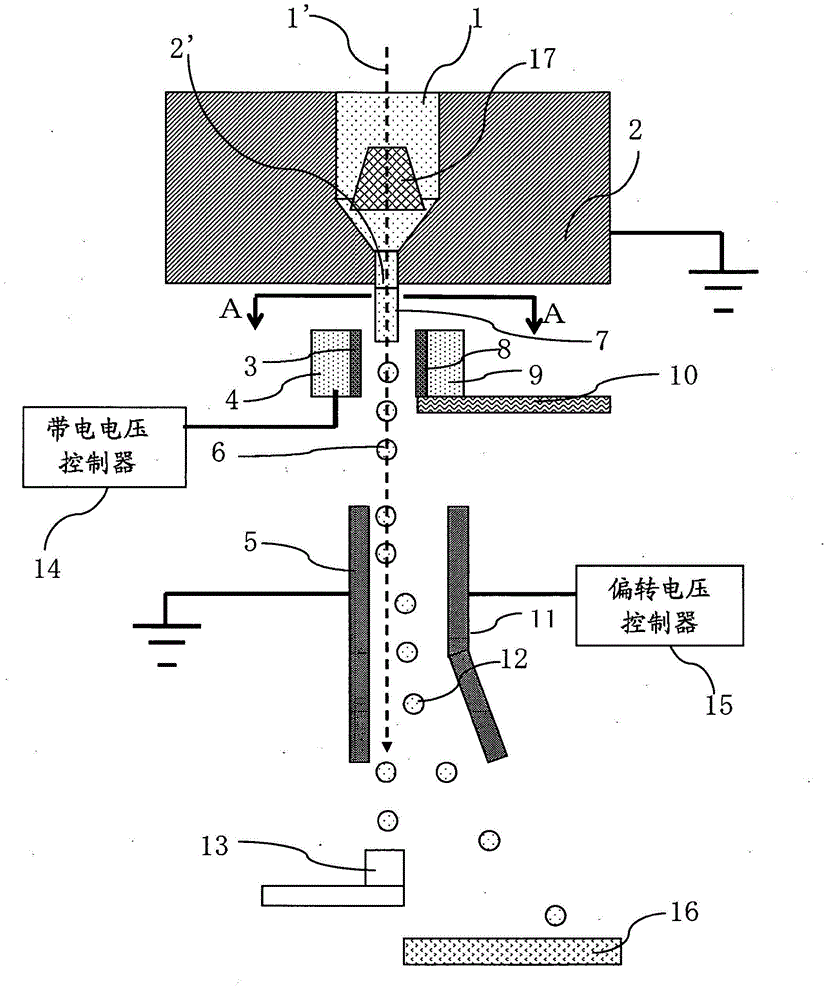

[0045] Embodiments of the present invention described below are applied to Figure 7 An example of the case of a continuous ejection type inkjet recording apparatus among the inkjet recording apparatuses shown.

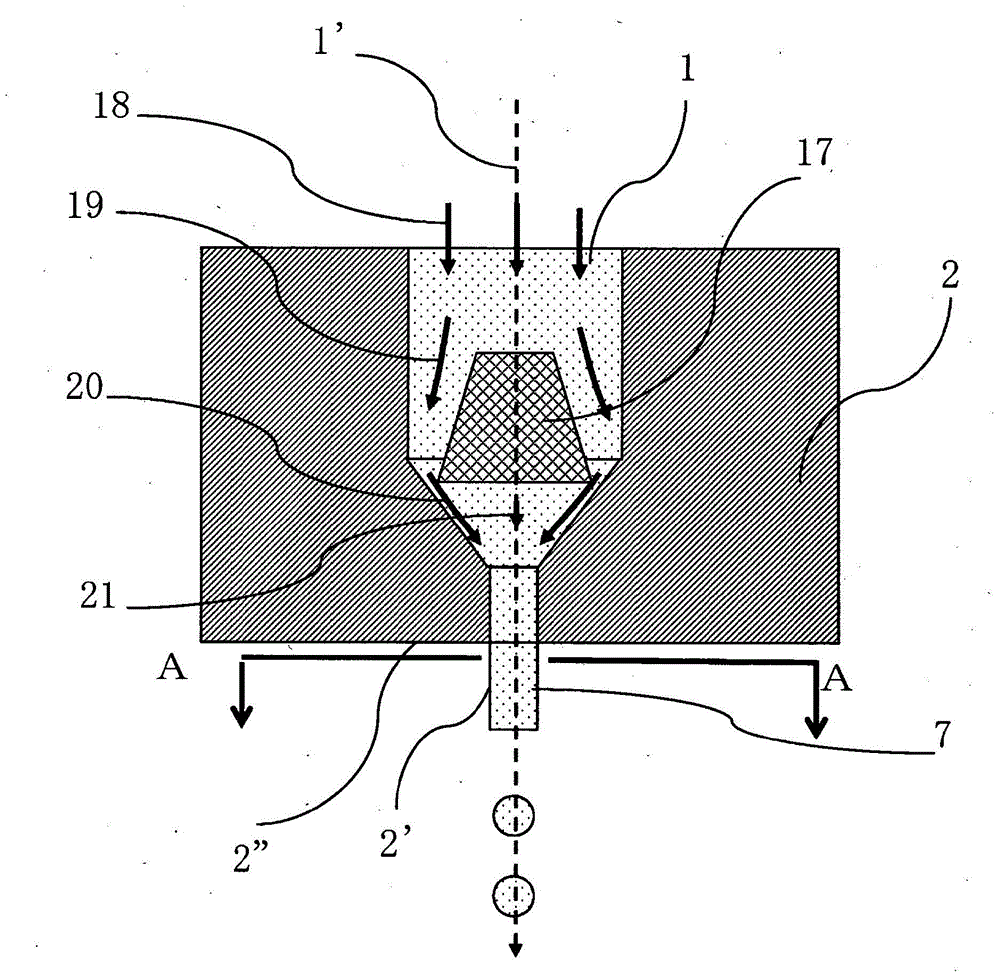

[0046] use figure 1 , 2 , 3, and 4 describe the schematic structure of, in particular, the nozzles of the inkjet head in the continuous discharge type inkjet recording device (or continuous inkjet device) as the first embodiment of the present invention.

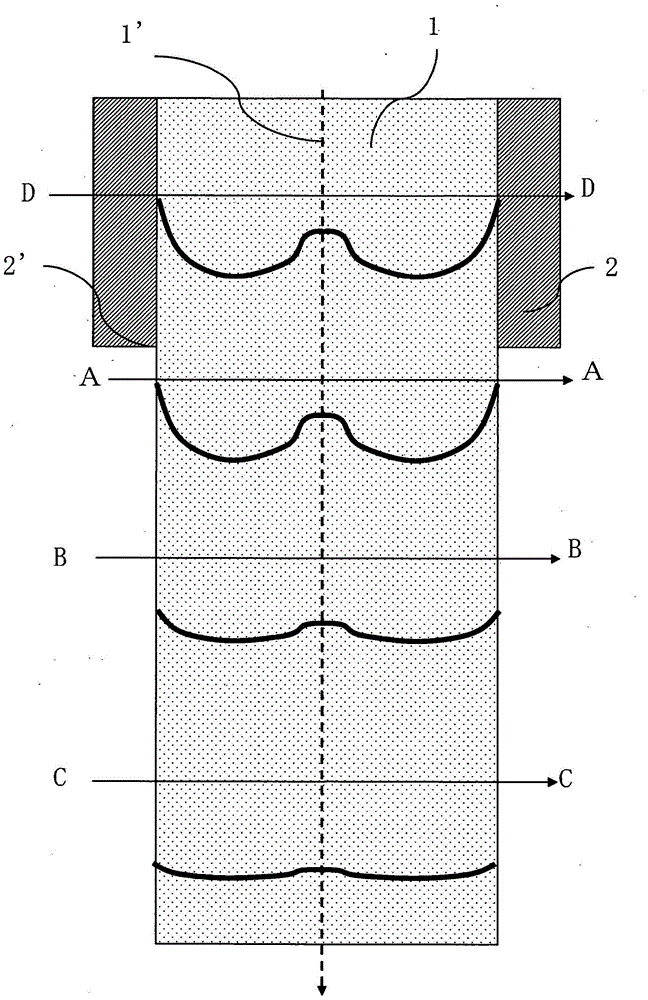

[0047] figure 1 is a structural diagram of main parts of the first embodiment of the present invention, showing Figure 7 A diagram of the internal structure of the inkjet head 32. figure 2 It is a structural diagram of the main part of the sprinkler head 2. image 3 is description figure 1 A detailed diagram of the variation of the velocity distribution of the ink near the AA section near the outlet of the ink chamber 1 in the traveling direction. Figure 4 It is a structural diagram of main parts of the fi...

no. 2 example

[0062] Next, a second embodiment of the present invention will be described.

[0063] Figure 5 It is a structural diagram of main parts of the second embodiment of the present invention. exist Figure 5 Other structures not shown in the figure 1 example of the same structure. exist Figure 5 Among them, the speed suppressing member 17 in the vicinity of the axis has a conical shape whose cross-sectional area becomes smaller along the traveling direction. With such a configuration, since the tip of the cone is brought closer to the nozzle outlet 2', a concave velocity distribution in which the velocity in the vicinity of the center axis can be further reduced can be generated, and there is an effect that the splitting distance can be shortened.

no. 3 example

[0065] Next, a third embodiment of the present invention will be described.

[0066] Figure 6 It is a structural diagram of main parts of the third embodiment of the present invention. exist Figure 6 Other structures not shown in the figure 1 example of the same structure. exist Figure 6 Among them, the speed suppressing member 17 in the vicinity of the axis has a double pipe structure that divides the flow of ink into the inner side and the outer side, and at the outlet, the inner side speed becomes slower than the outer side speed. This velocity distribution is obtained by making the cross-sectional area of the outer side of the double pipe smaller than that of the inner side at the inlet and larger at the outlet.

[0067] With such a configuration, the velocity distribution can be controlled by selecting the inner and outer diameters of the double-layer tube, and therefore, there is an effect that the cutting distance can be easily designed in accordance with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com