Patents

Literature

39 results about "Capillary wave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A capillary wave is a wave traveling along the phase boundary of a fluid, whose dynamics and phase velocity are dominated by the effects of surface tension. Capillary waves are common in nature, and are often referred to as ripples. The wavelength of capillary waves on water is typically less than a few centimeters, with a phase speed in excess of 0.2–0.3 meter/second.

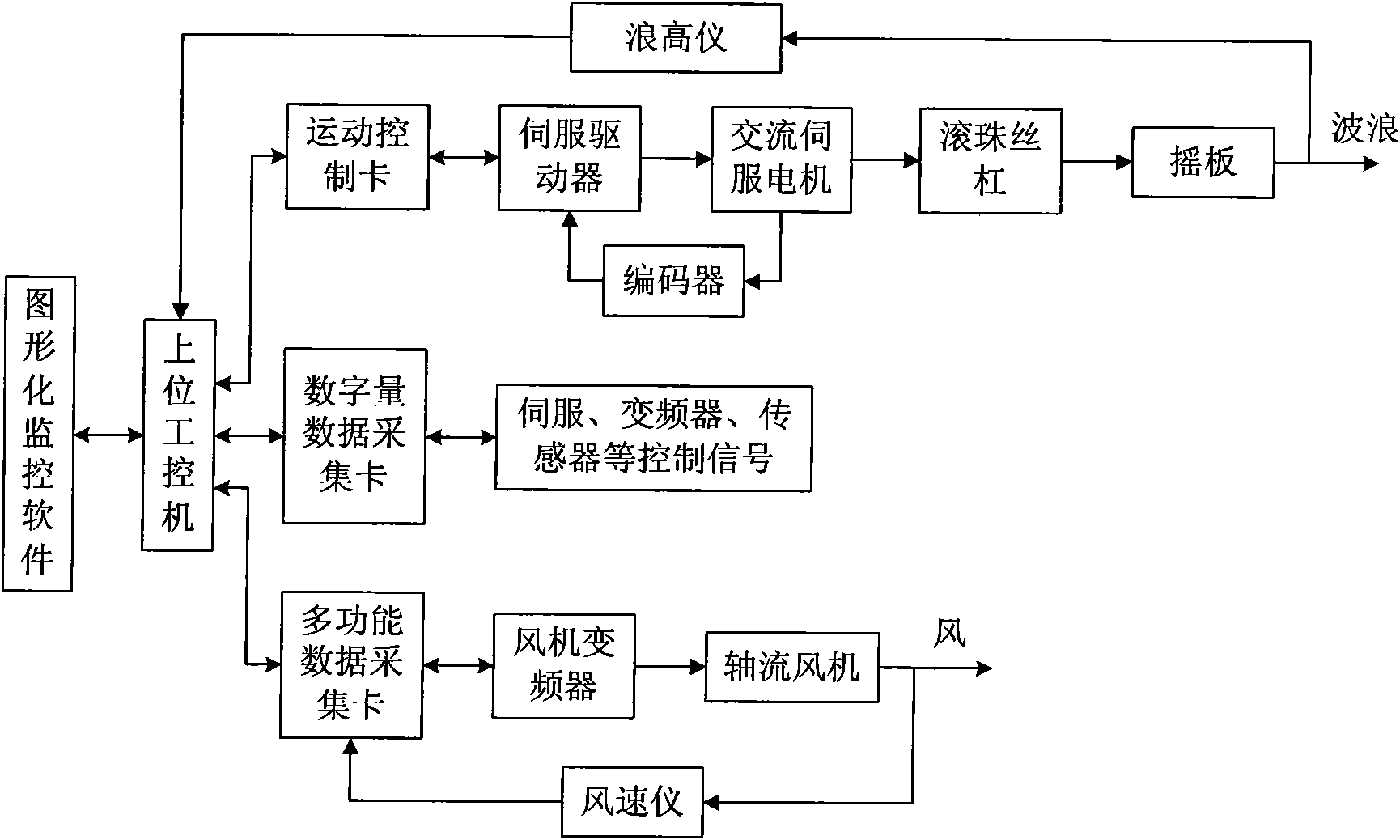

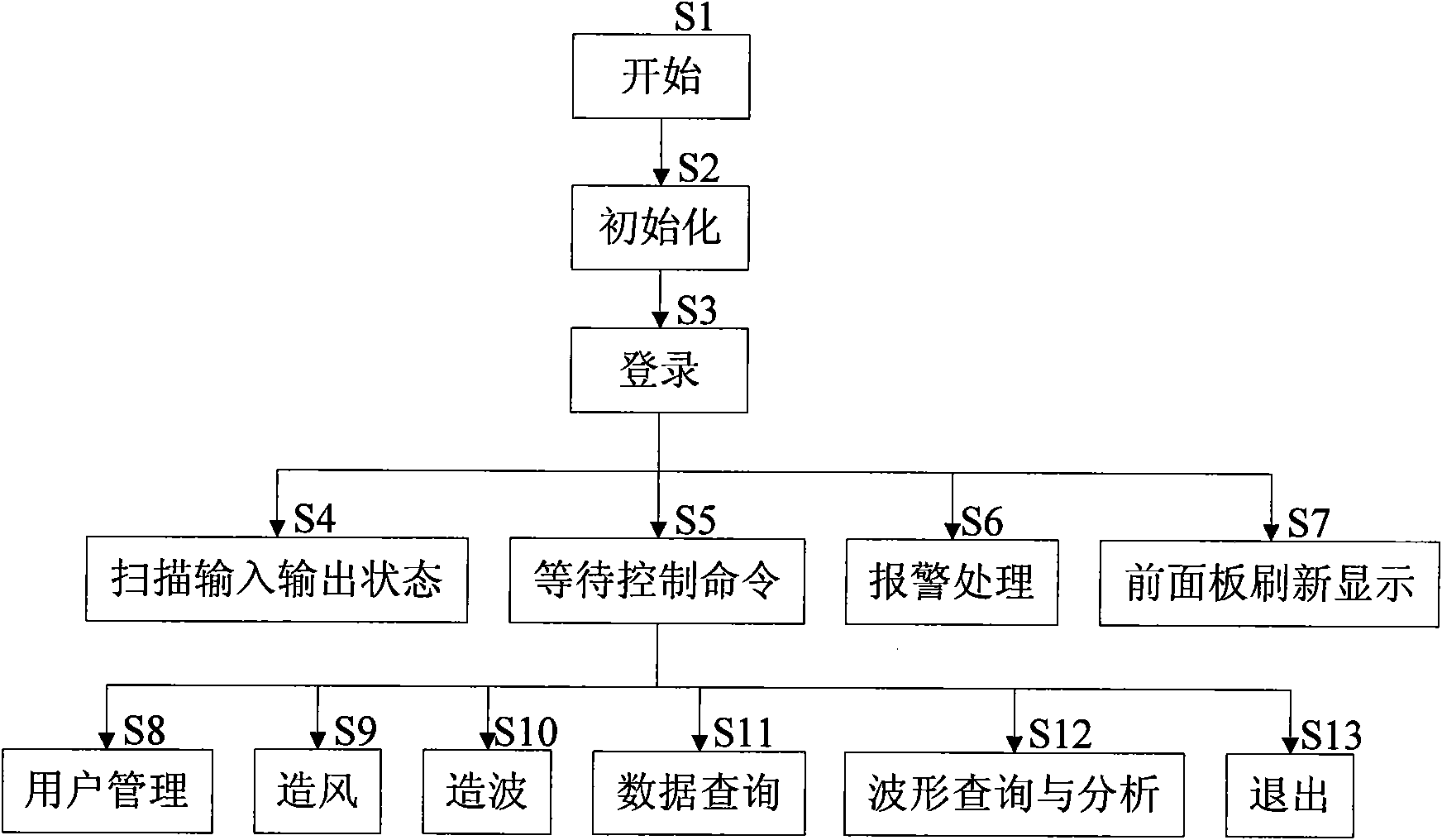

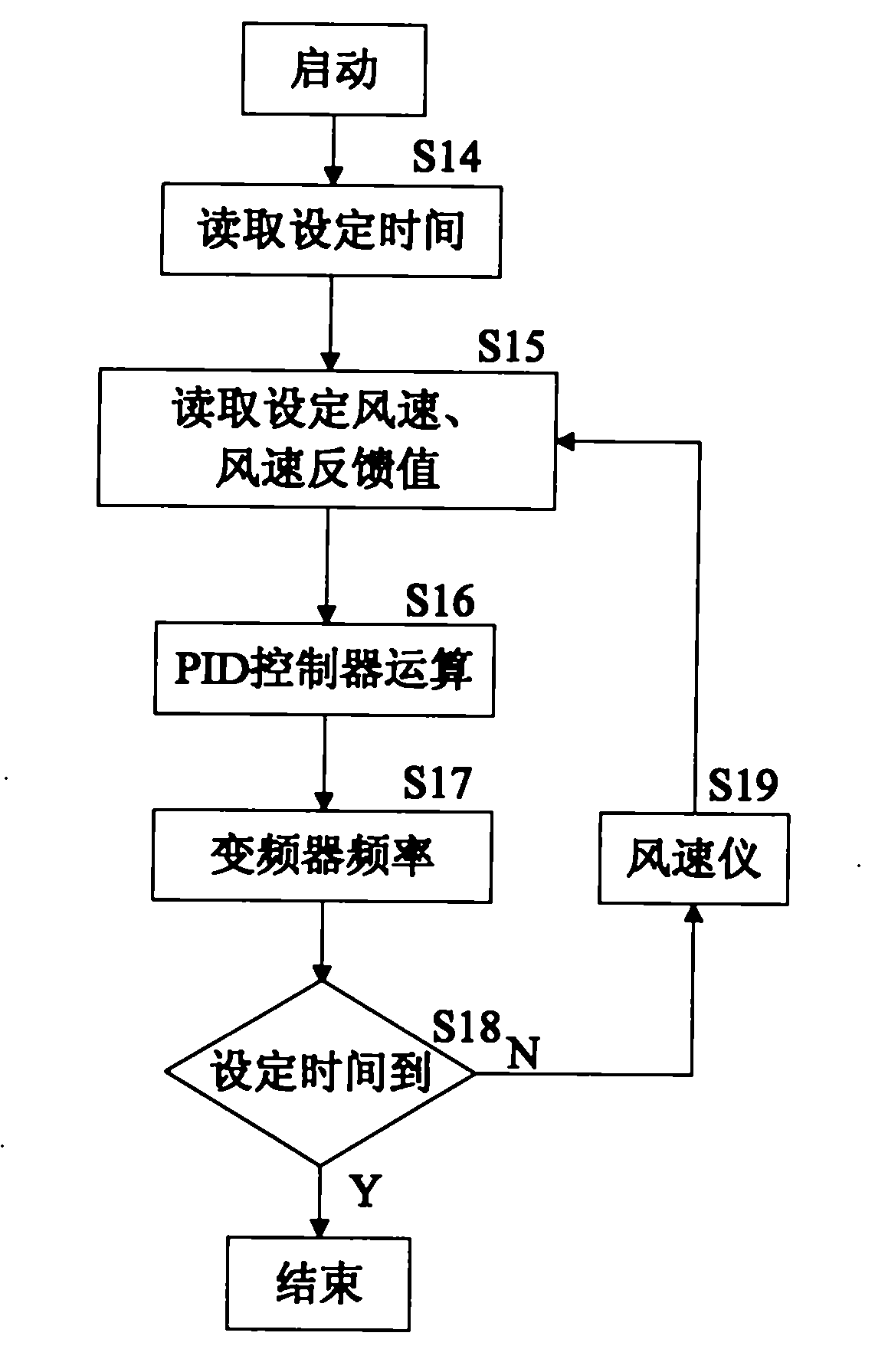

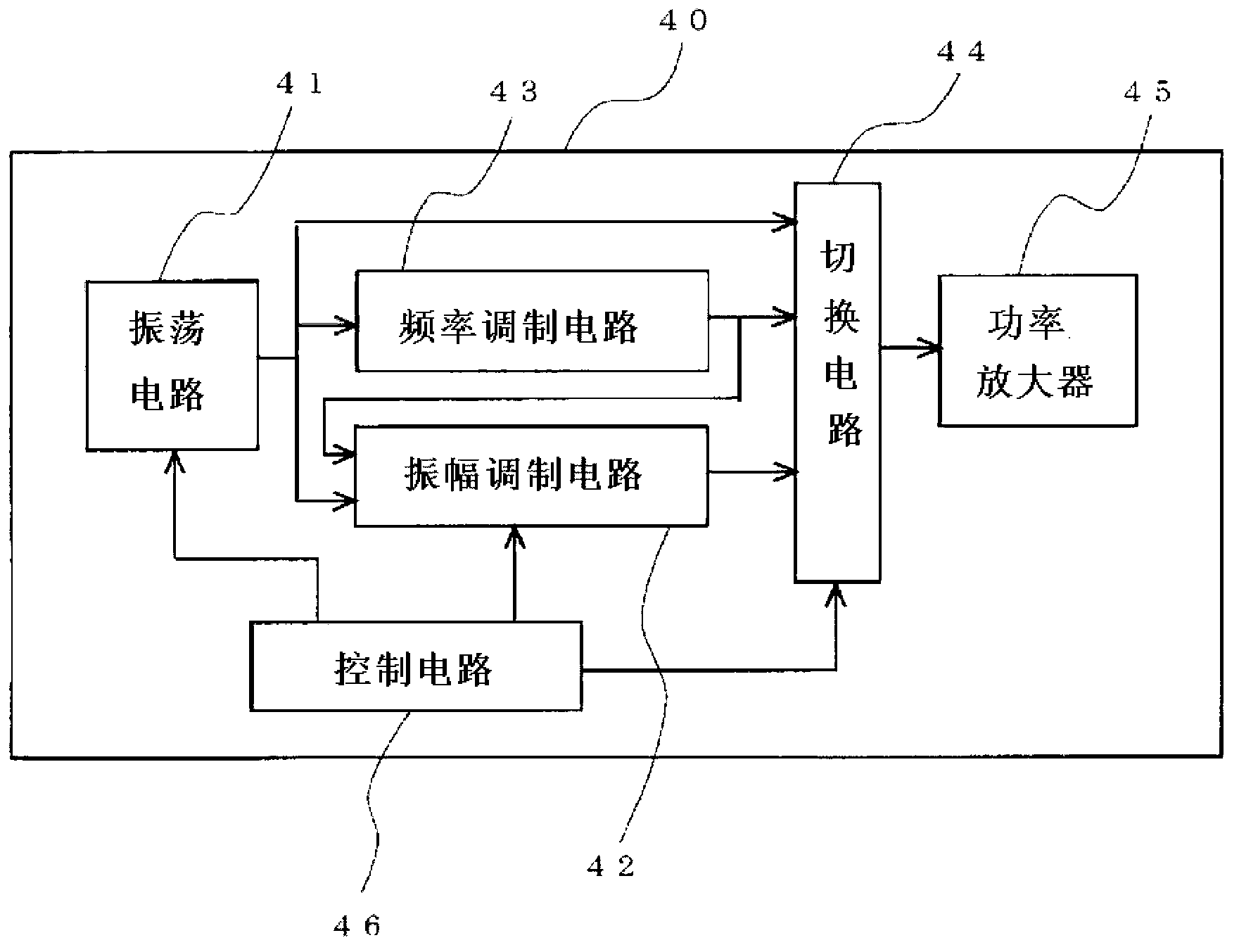

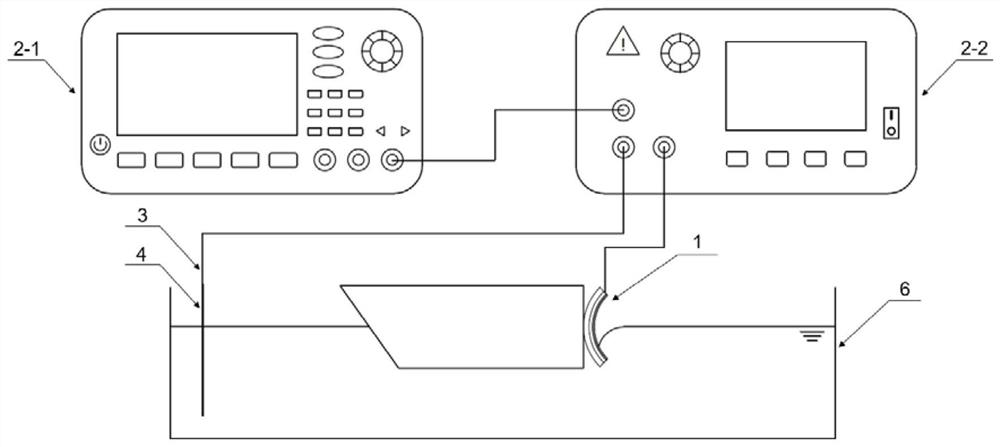

Closed loop control method for indoor wind wave water tank wave maker

InactiveCN101968636AClosed-loop control effect is goodThe control principle is safe and reliableProgramme controlComputer controlLoop controlComputer monitoring

The invention belongs to the technical field of a wave maker control system and relates to a closed loop control method for a small indoor wind wave water tank wave maker, in particular to a closed loop control system integrating hardware with software. In the method, a wave height meter acquires wave height data, serving as a feedback signal for wave-making control, in real time to form the closed loop control for a rocker panel wave making process; an anemometer measures the wind speed, serving as a feedback signal for wind-making control, in real time in an air flue to form the closed loop control for a fan wind making process; and a rocker panel-made shallow water wave and a fan-made capillary wave are in telecommunication with each other to form the closed loop control system. A system device for realizing the closed loop control comprises an upper computer monitoring module, a wave-making module and a wind-making module. The method has a safe and reliable control principle, good closed loop control effect on wave-making and wind-making functions and high automation degree, can realize integrated mechanical wind-making and wind-making wave-making simulation and can be widely applied to the wave-making occasions of various small indoor wave makers to form the integrated closed control systems.

Owner:QINGDAO ZHONGMENG ELECTRONICS TECH

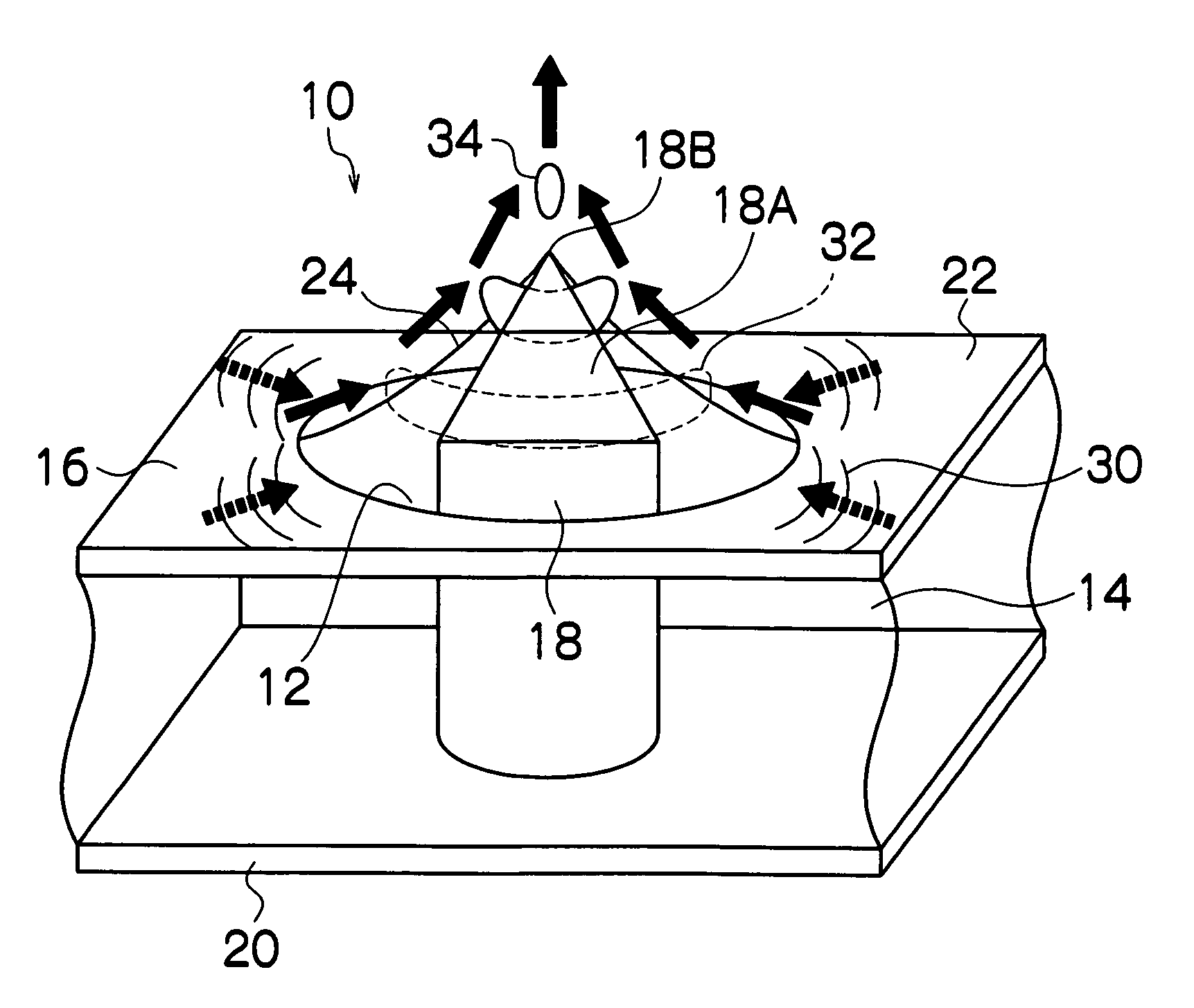

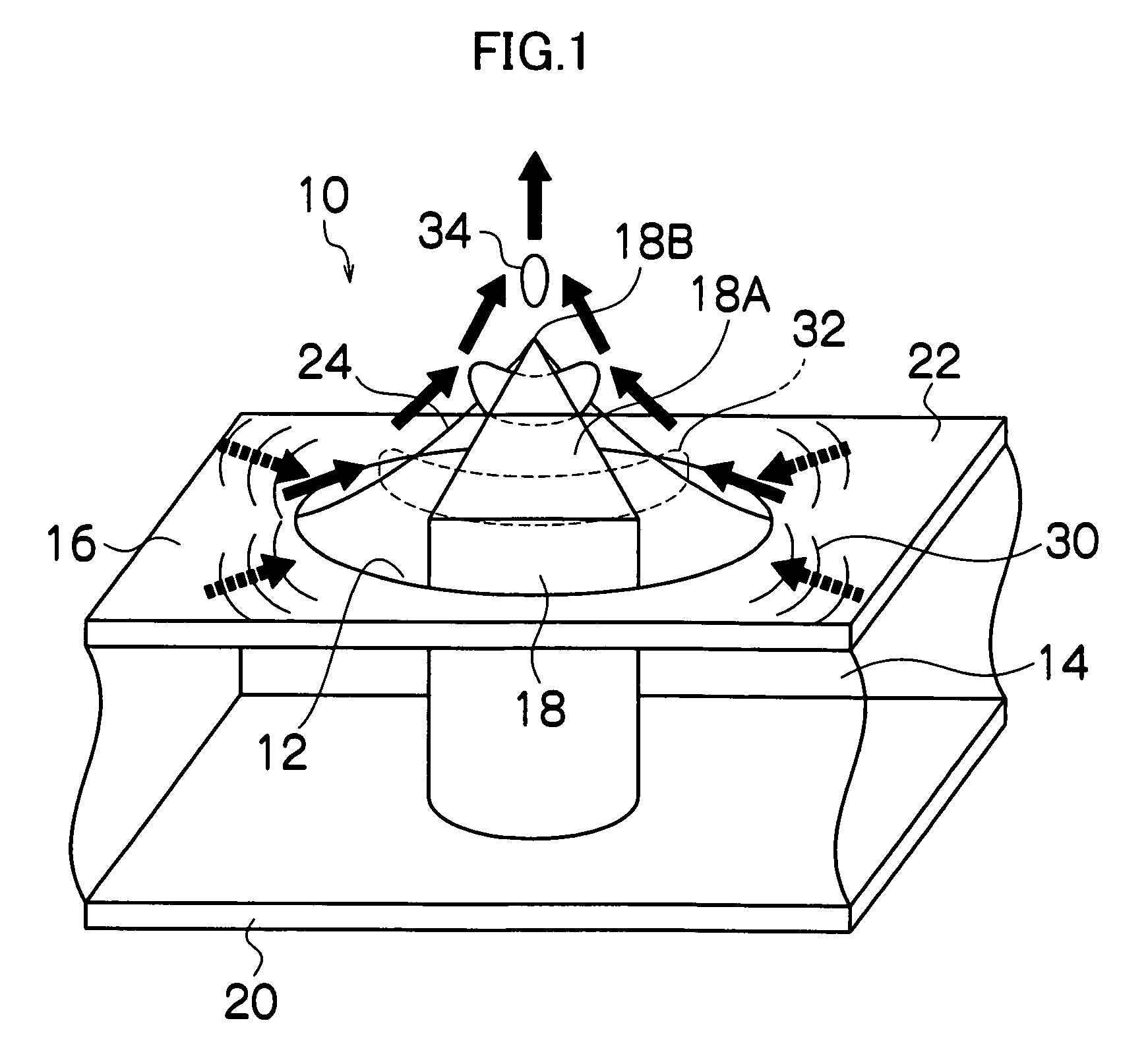

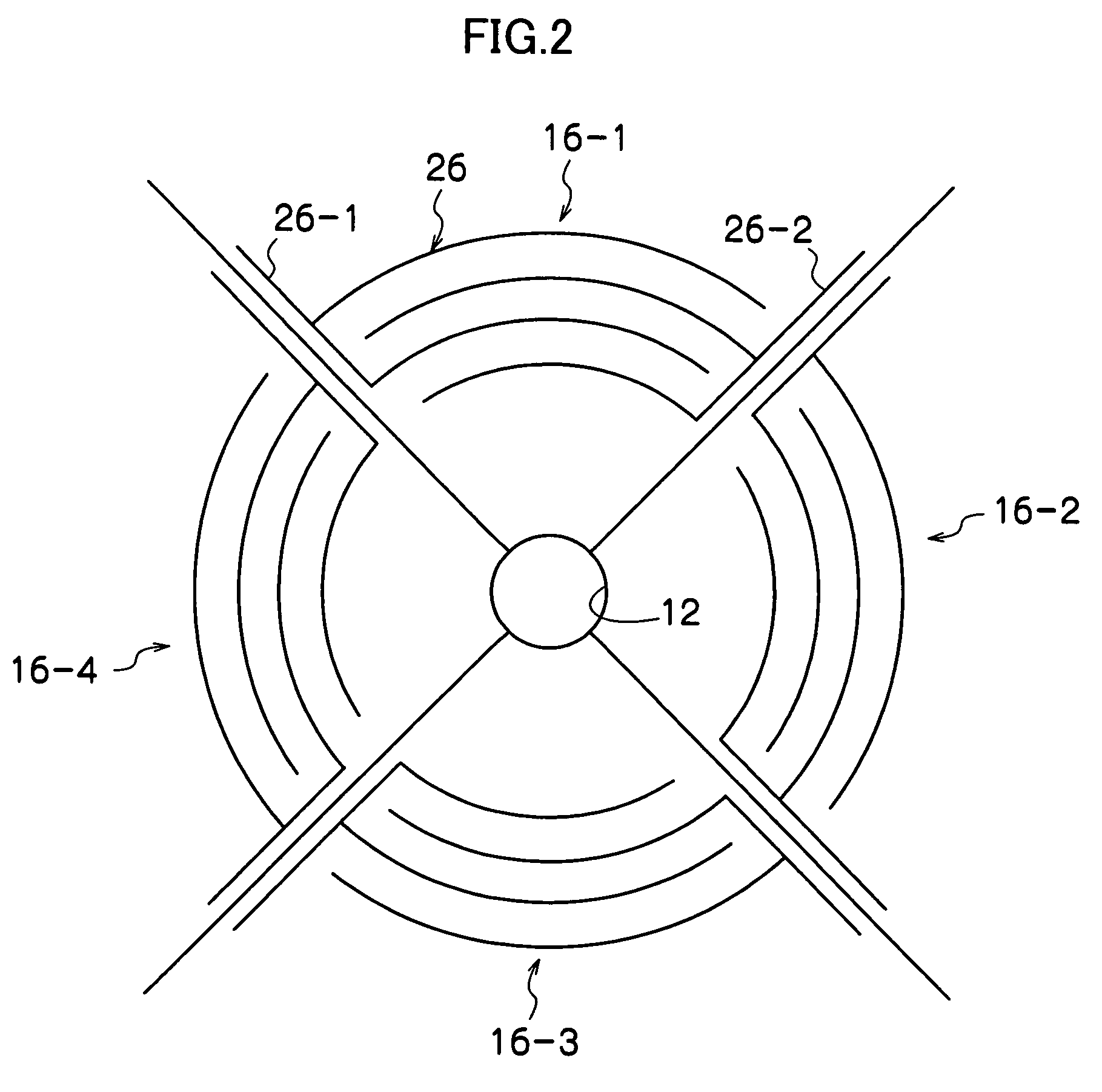

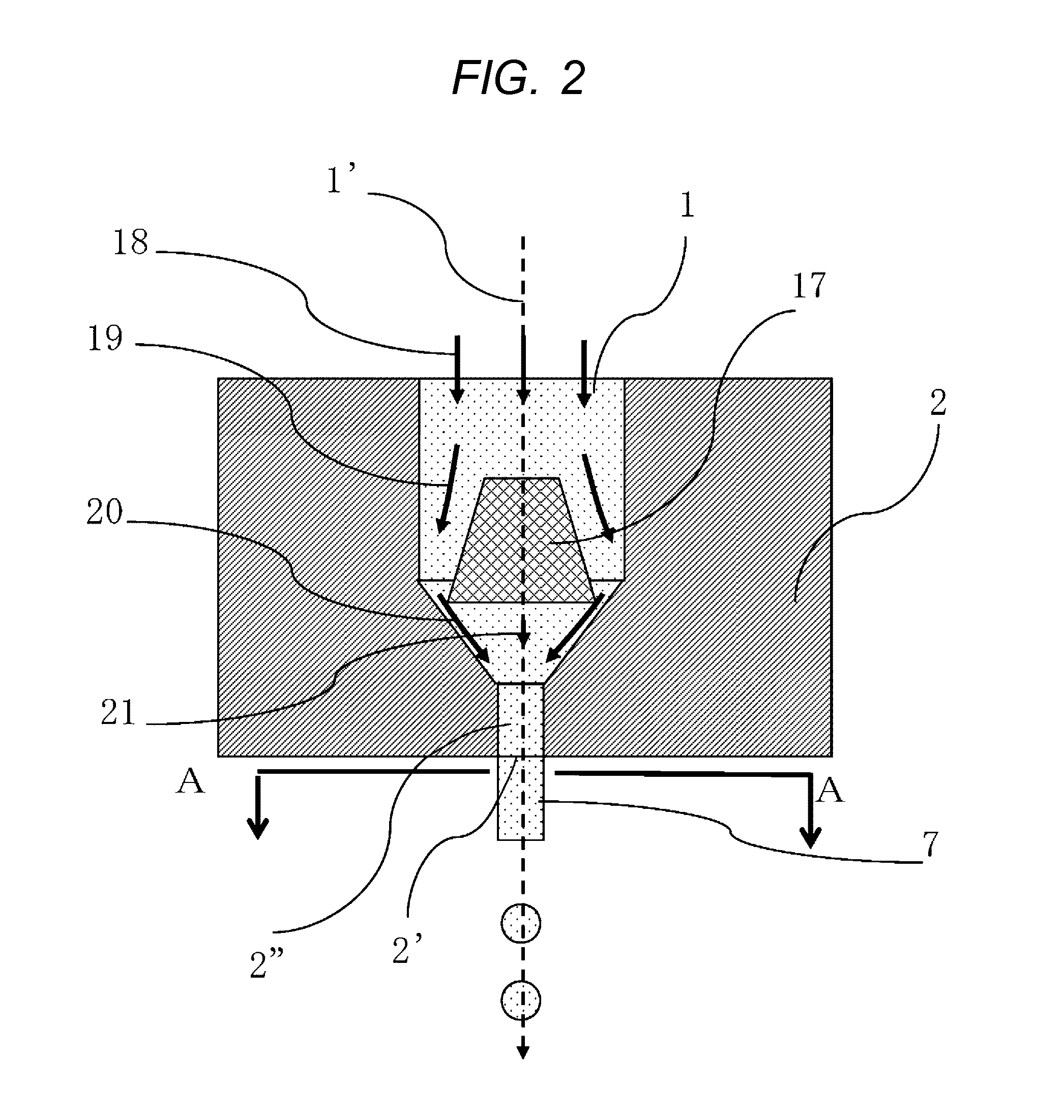

Liquid ejection head and image forming apparatus

InactiveUS7471028B2Easy to controlIncrease volumePiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesAcoustic waveSurface acoustic wave

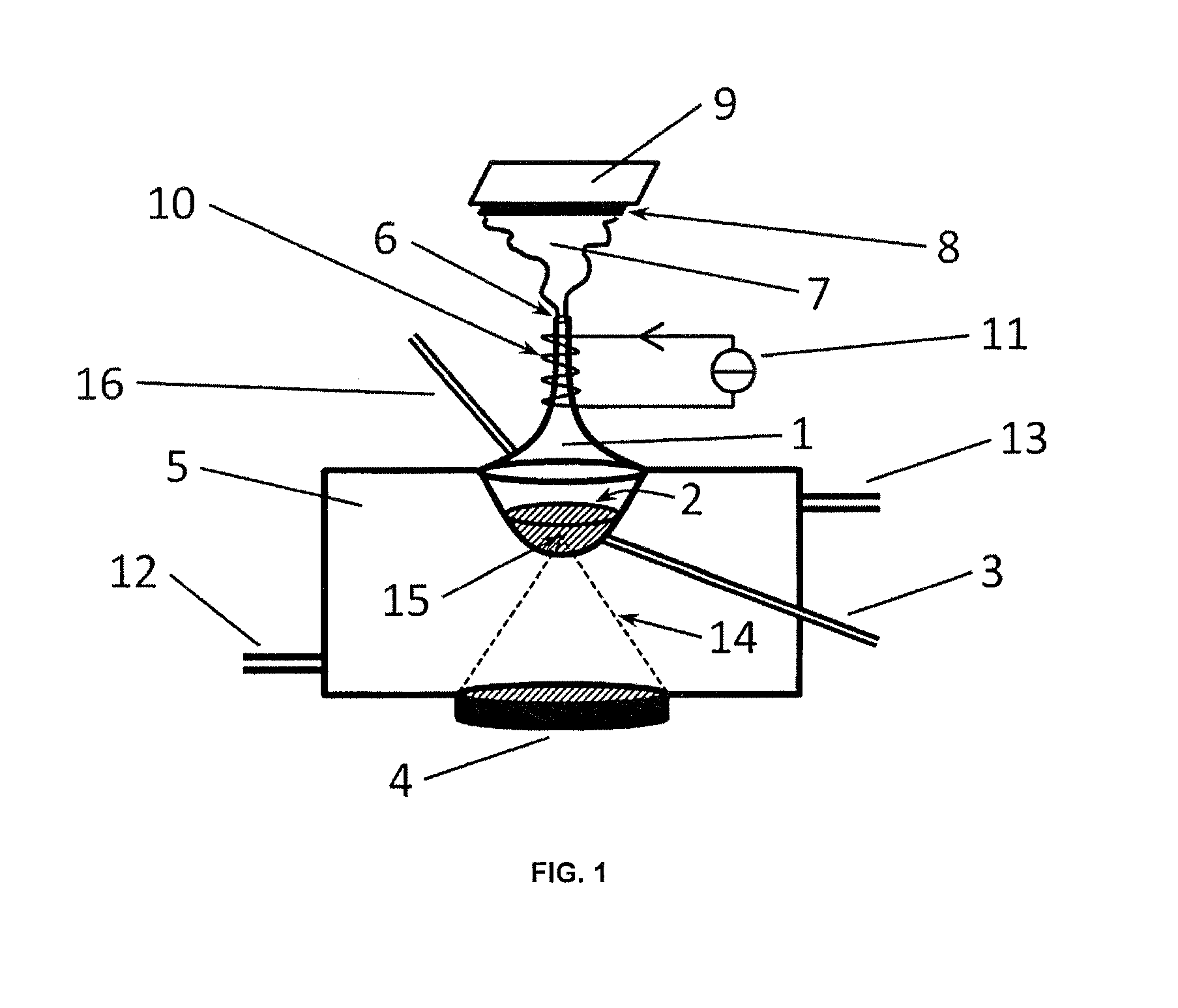

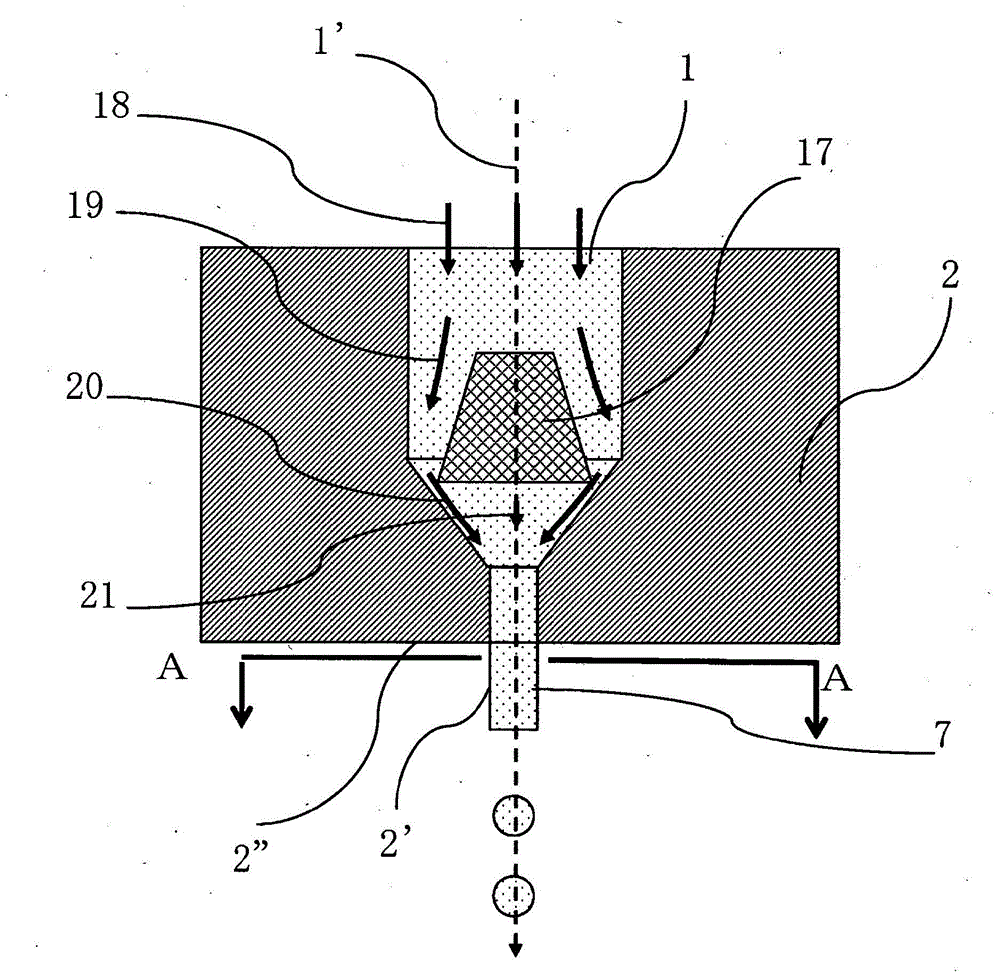

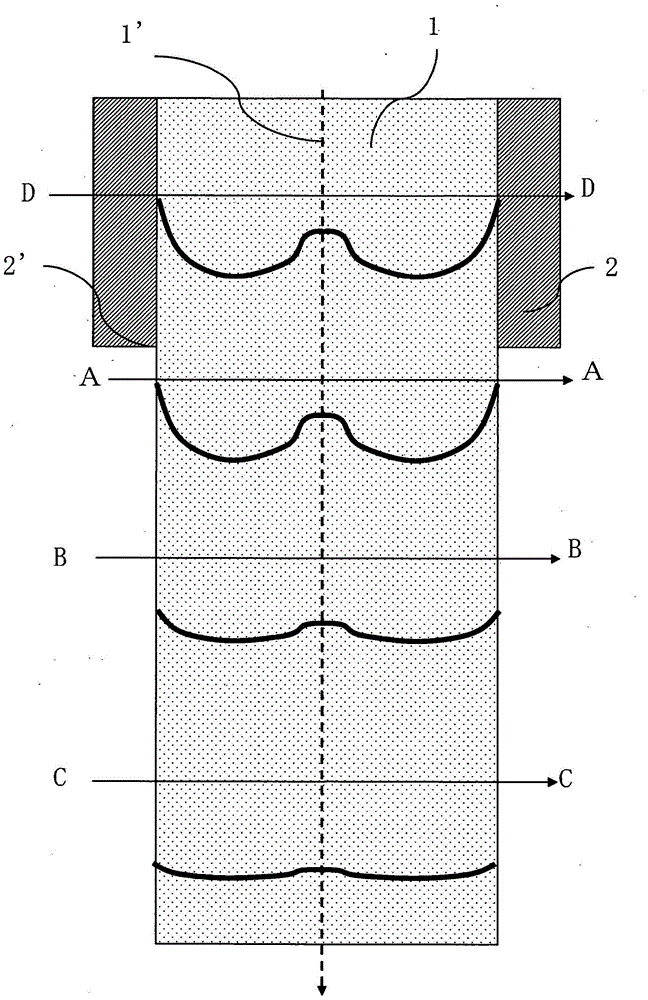

The liquid ejection head has: a surface acoustic wave propagation body in which a surface acoustic wave propagates; a nozzle orifice formed in the surface acoustic wave propagation body; a surface acoustic wave generation device which is provided on the surface acoustic wave propagation body around the nozzle orifice and excites the surface acoustic wave propagation body so that a surface acoustic wave is generated in the surface acoustic wave propagation body; a liquid supply device which supplies liquid to the nozzle orifice; and a guide member which is provided in a center of the nozzle orifice and has a tapered conical surface shape section that projects from an ejection surface of the nozzle orifice in an ejection direction, the liquid forming a curved liquid surface in the nozzle orifice in accordance with the tapered conical surface shape section due to surface tension, wherein the surface acoustic wave generates a capillary wave which propagates through the curved liquid surface in the nozzle orifice and which ejects the liquid from an apex section of the tapered conical surface shape section.

Owner:FUJIFILM CORP

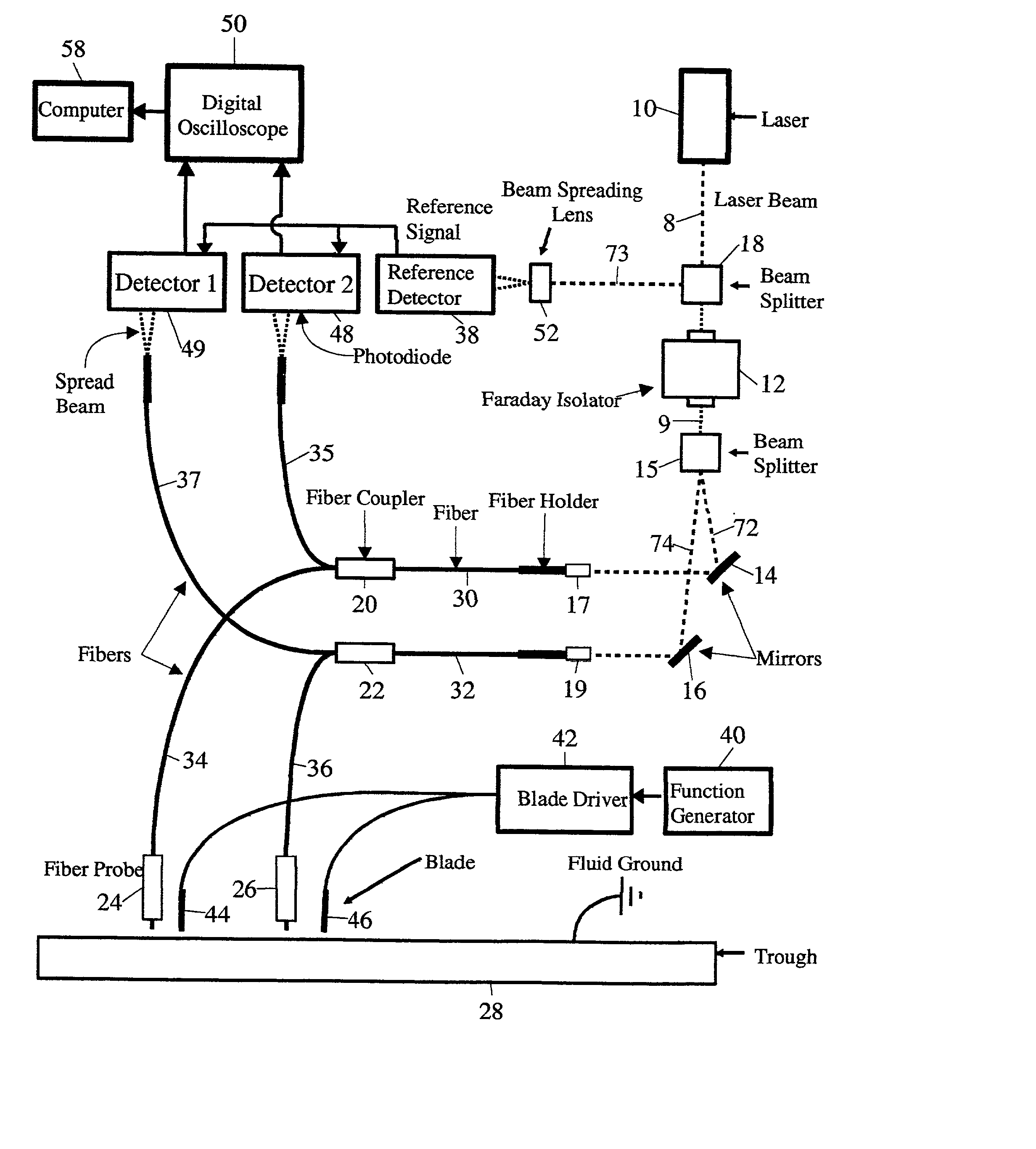

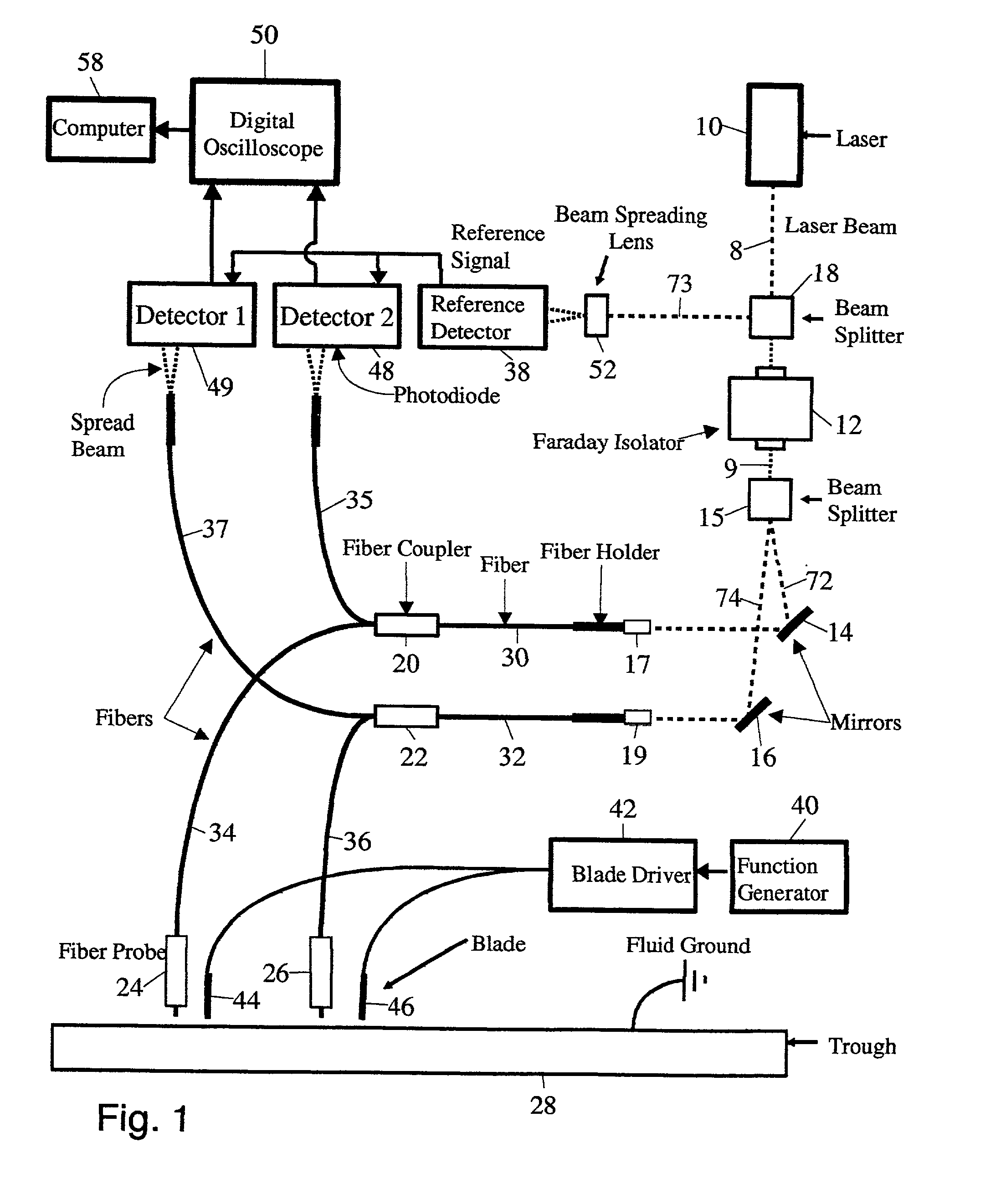

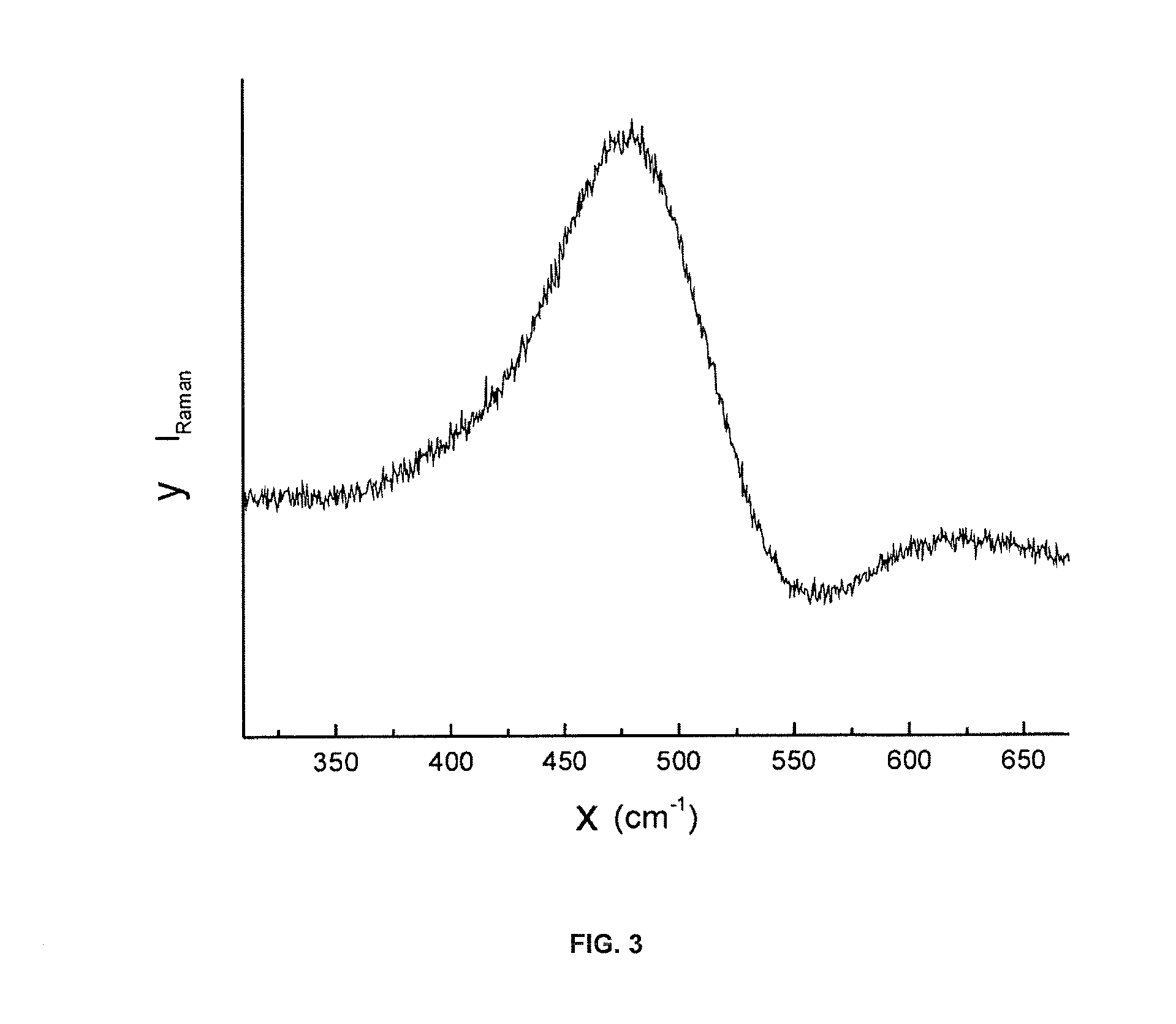

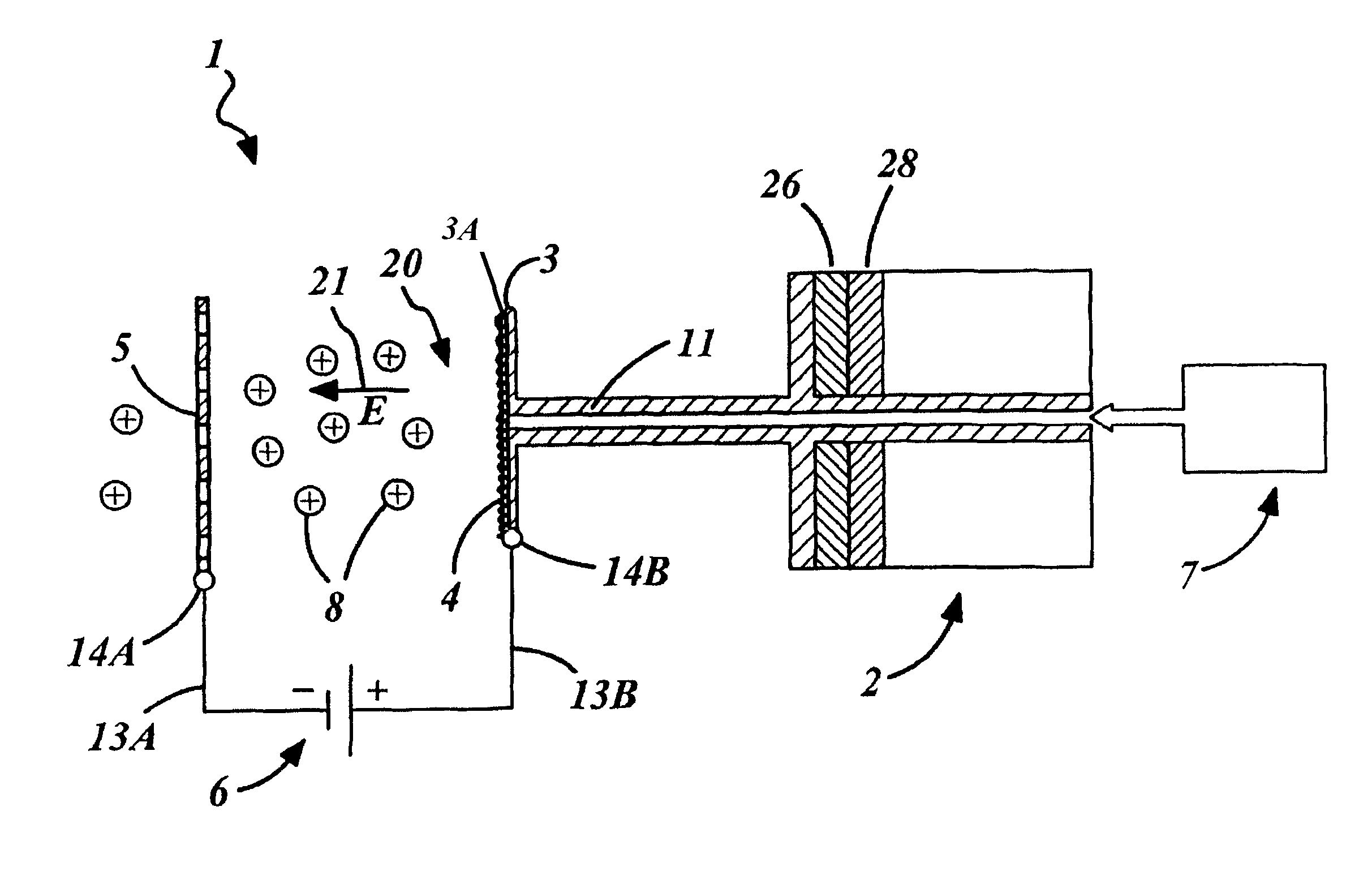

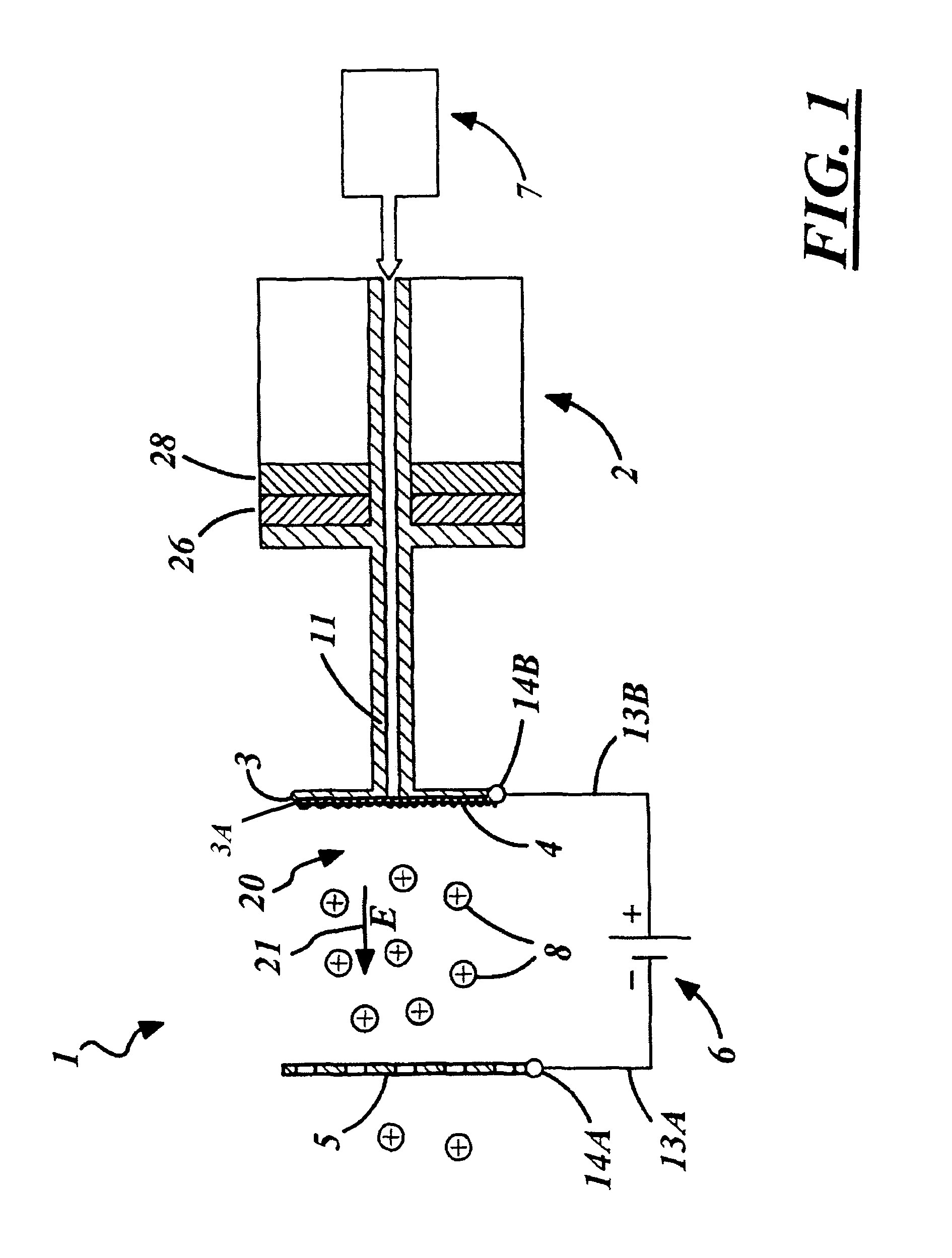

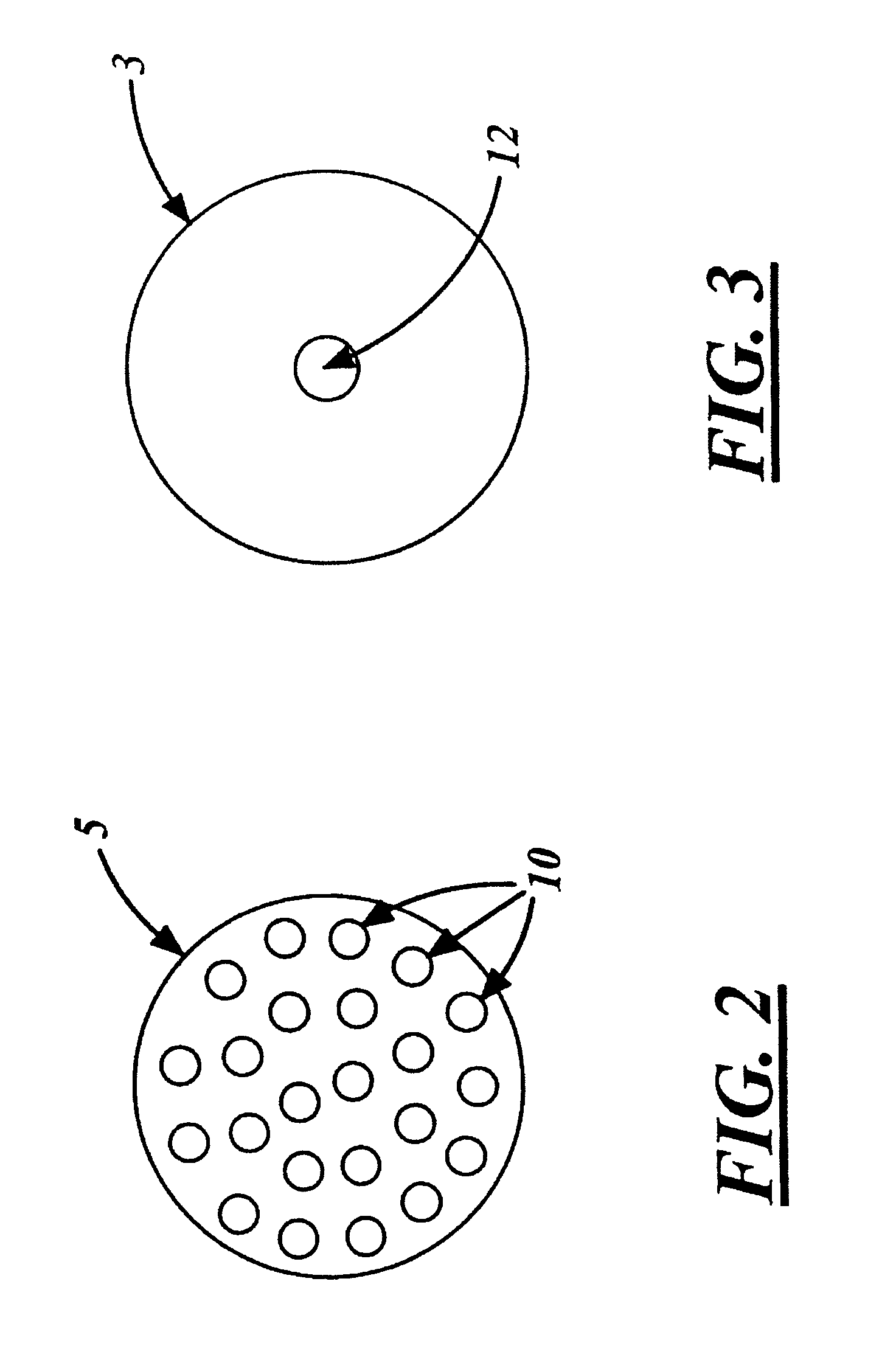

Apparatus and method for measurement of fluid viscosity

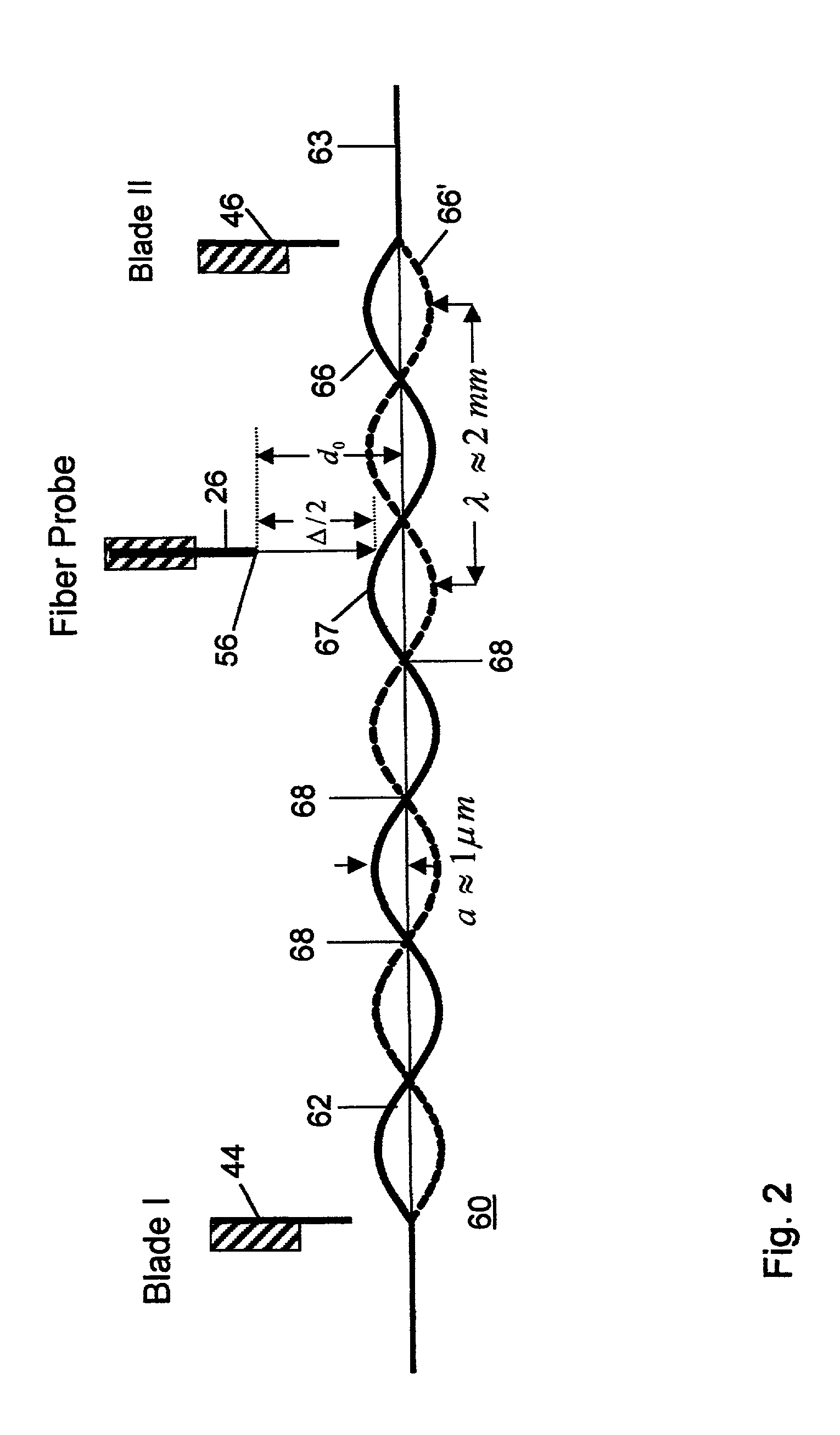

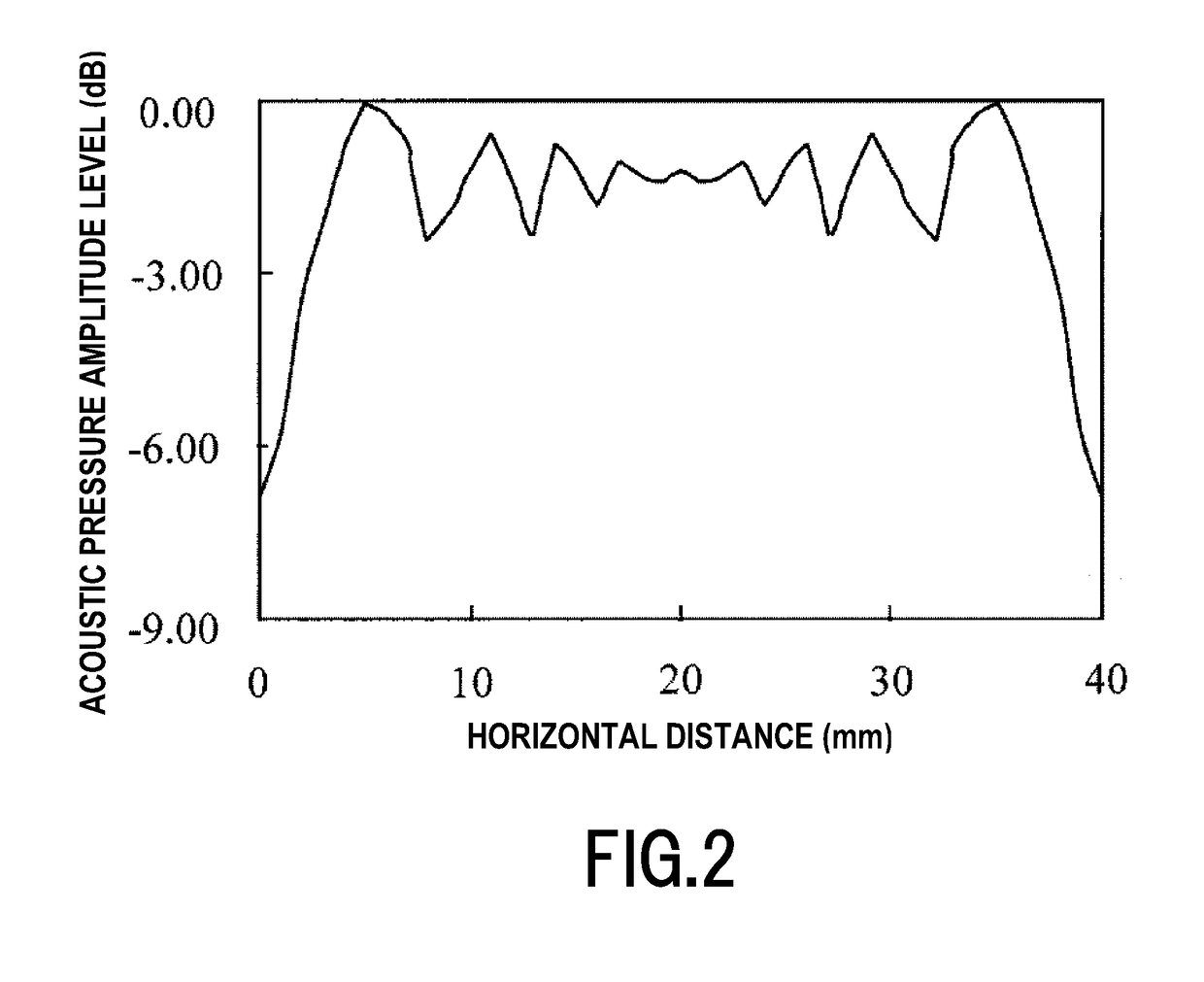

A non-contact apparatus and method for mapping the wave profile of capillary waves on a fluid surface to determine viscosity of the fluid. Two conducting blades coupled to a sine wave generator are positioned spaced laterally above and near the surface of the fluid to generate a standing capillary wave on the fluid surface between the blades. A laterally moveable fiber optic probe is coupled to a laser to transmit laser light toward the fluid surface and to receive reflected light from the fluid surface. Part of the laser light reflects from the end of the probe and creates an interference pattern with the light reflected from the fluid surface. The light reflected from the end of the probe and from the fluid surface are combined to form an interference signal which is analyzed to obtain the amplitude of the wave directly under the probe. By moving the probe laterally, nodes on the standing wave may be detected to find the wavelength of the capillary wave. One blade may be decoupled from the sine wave generator and the fiber optic probe moved laterally to determine the wave amplitude of a traveling wave as a function of distance which is then used to determine viscosity.

Owner:UNIV OF NORTHERN IOWA RES FOUND

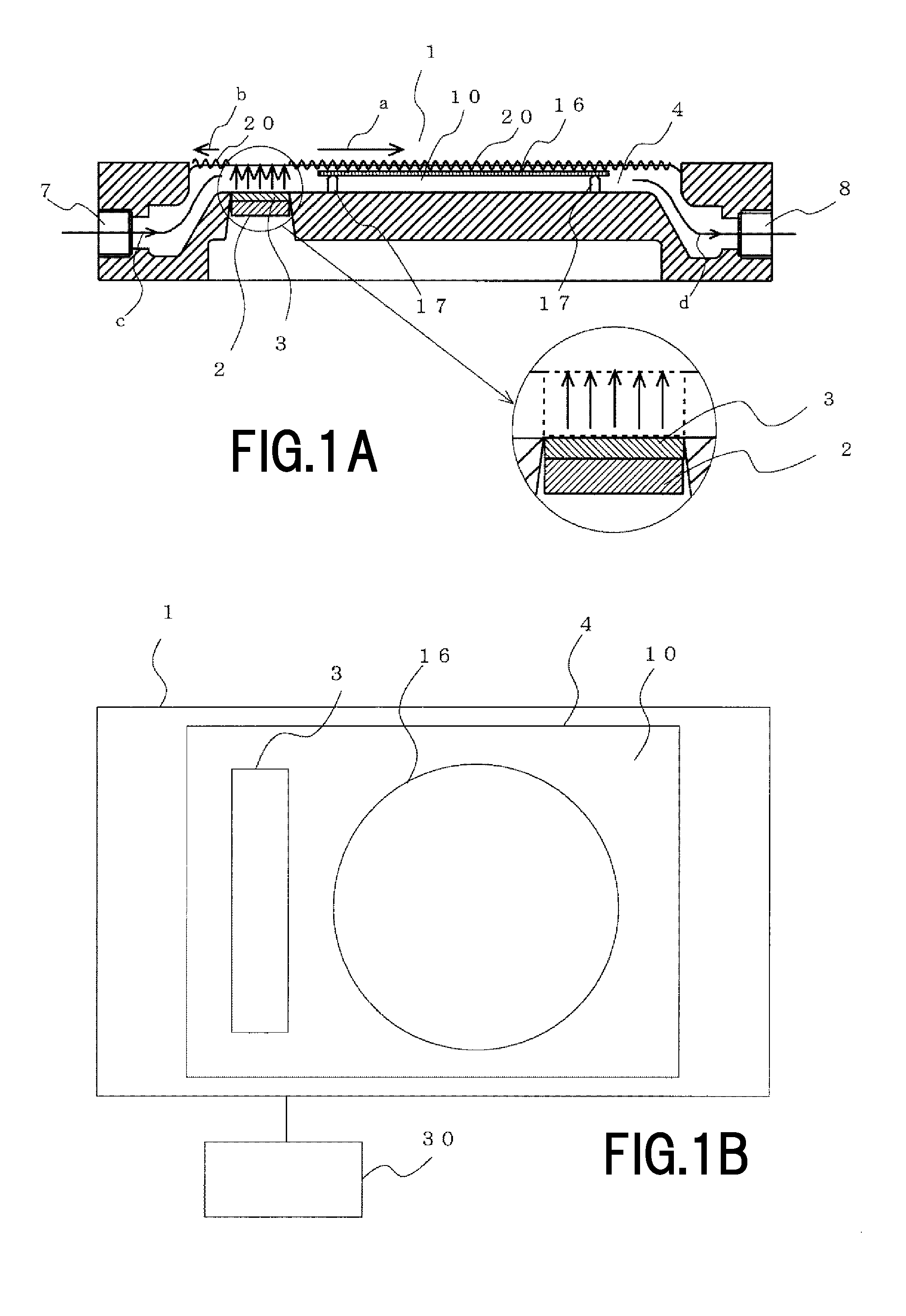

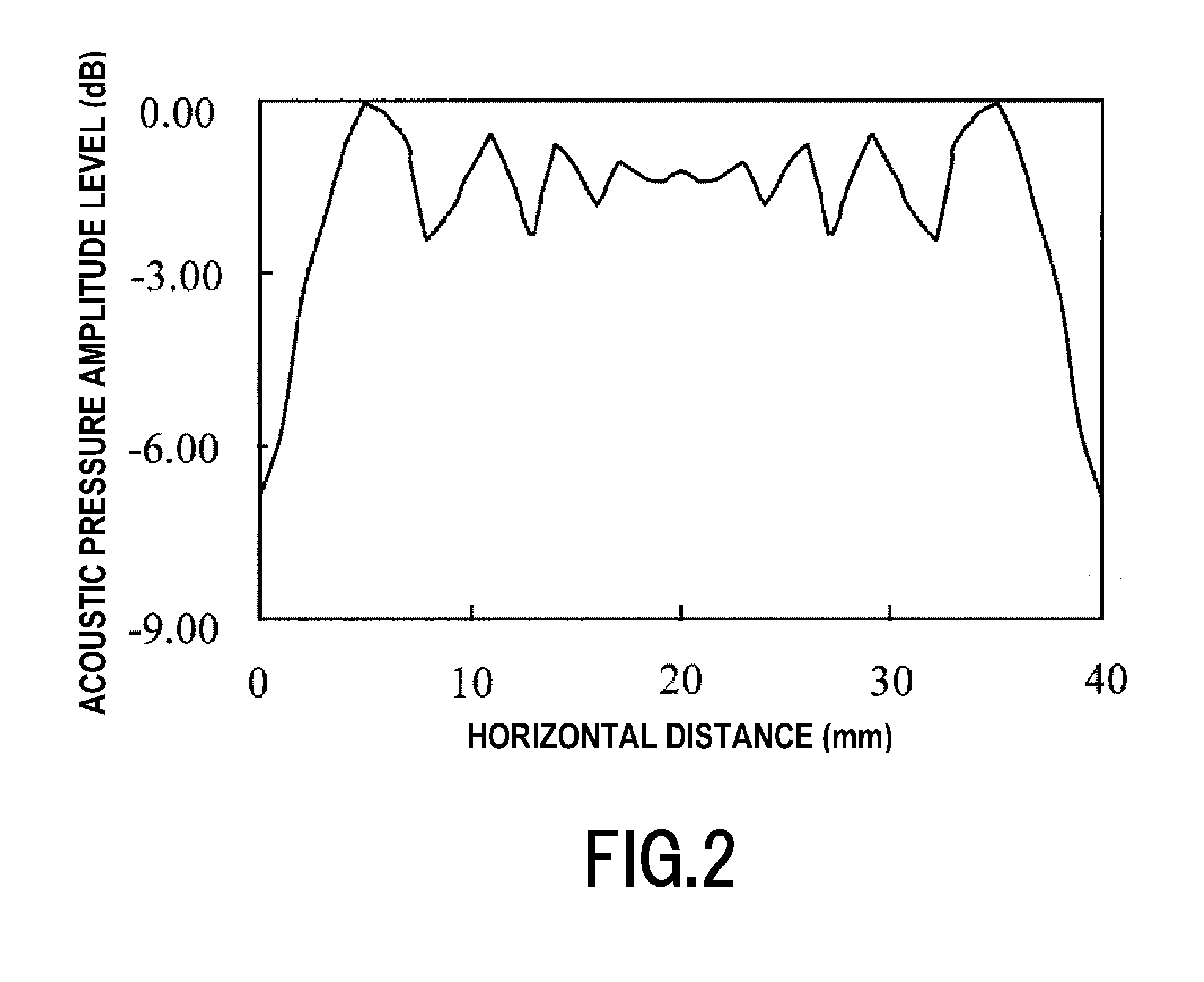

Ultrasonic cleaning device and ultrasonic cleaning method

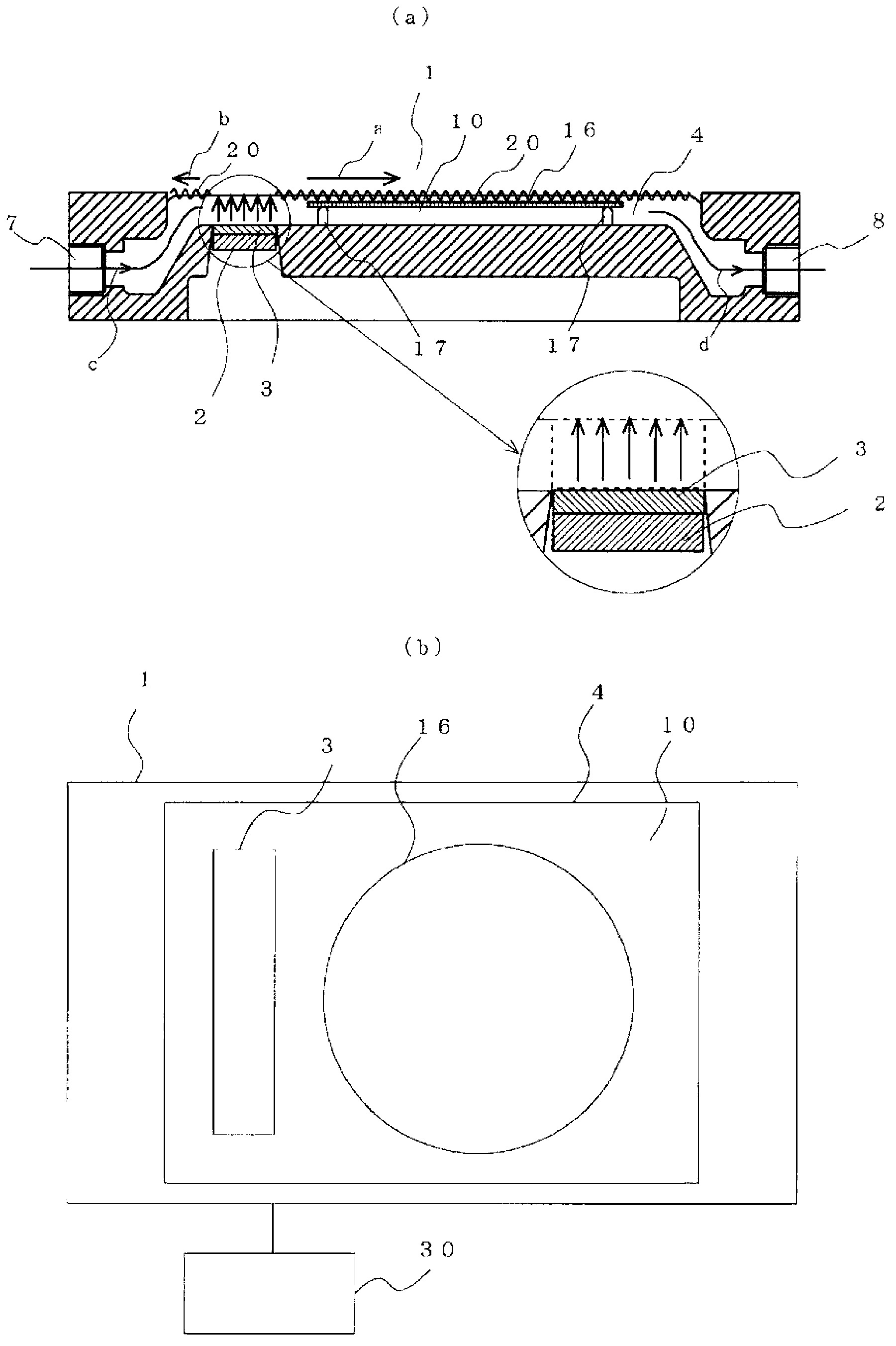

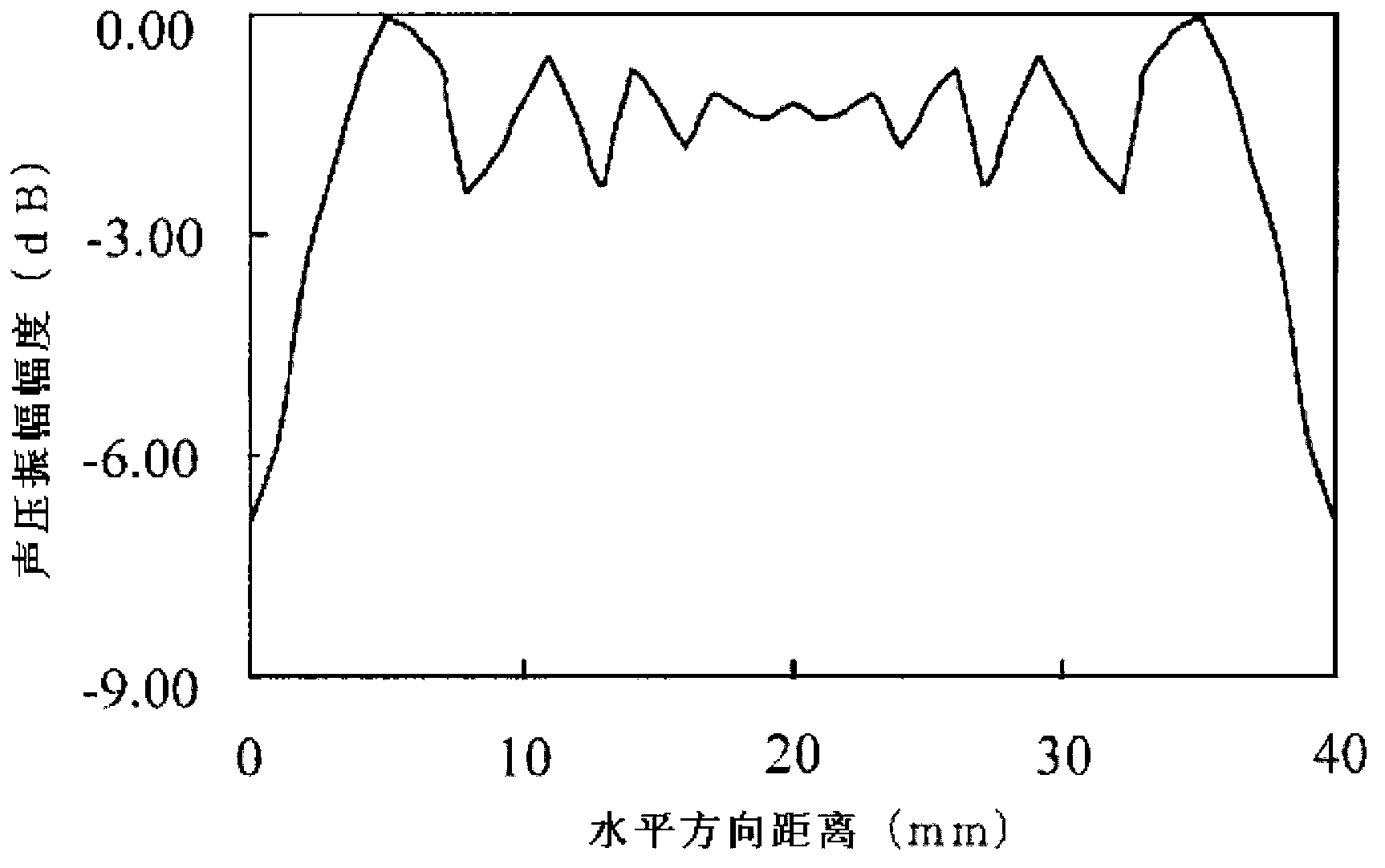

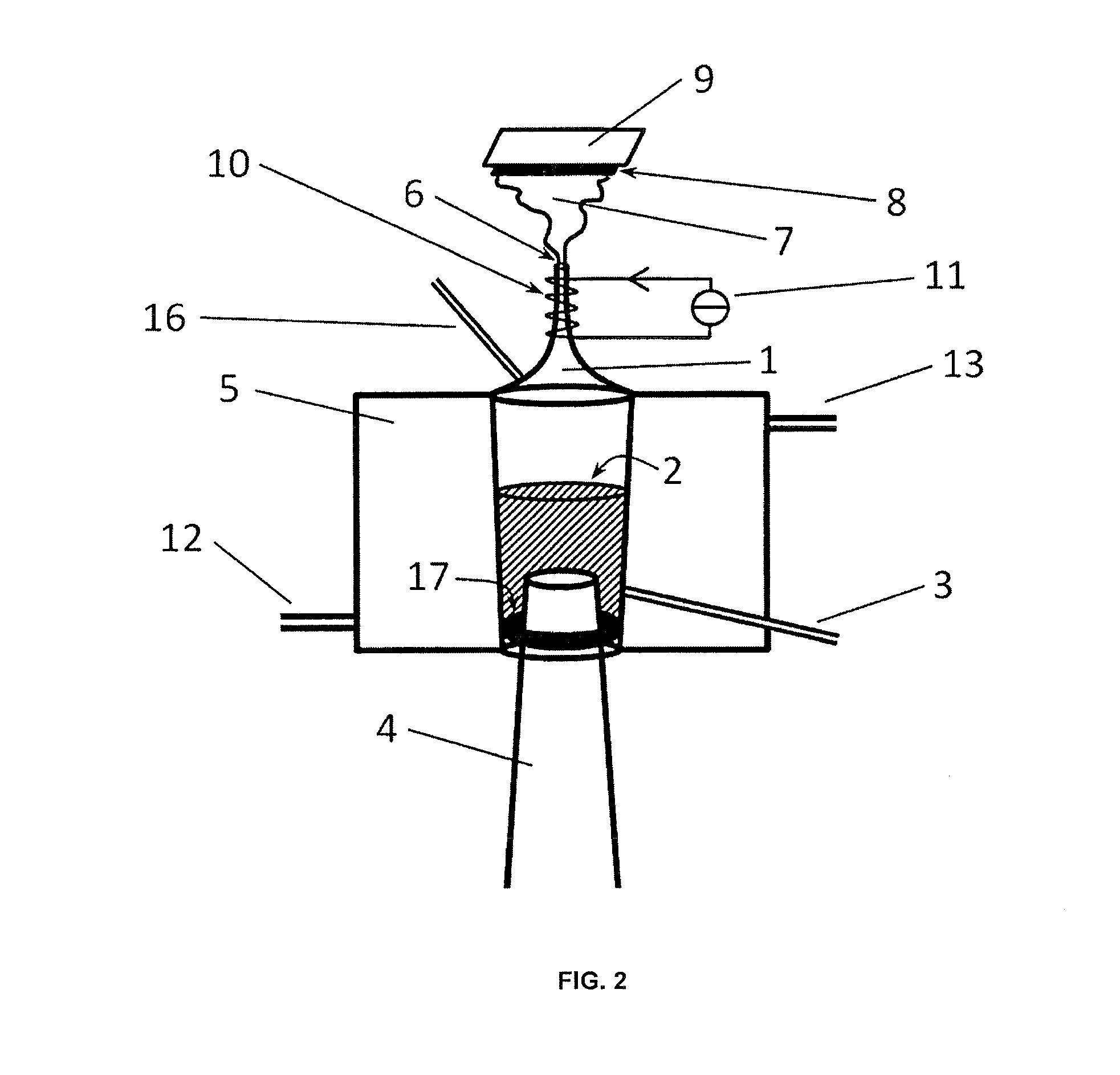

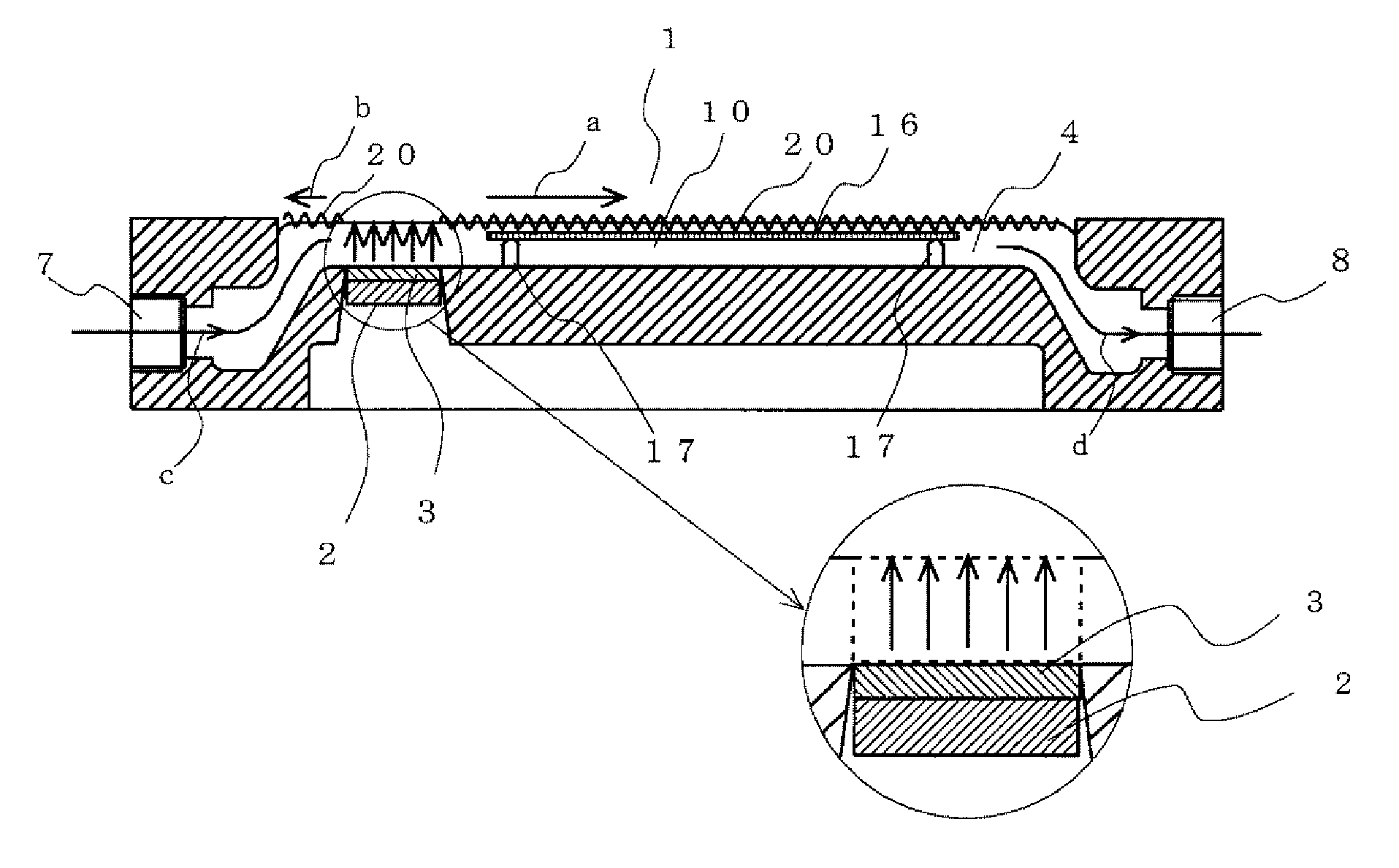

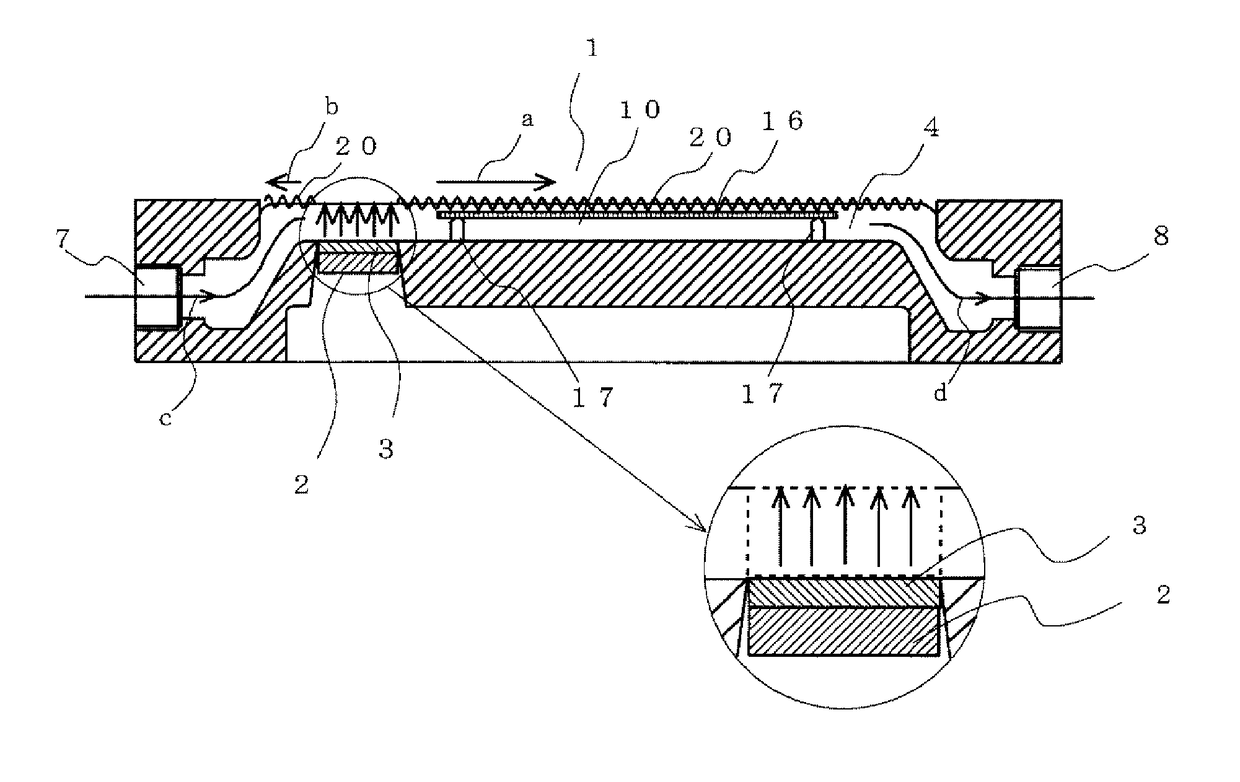

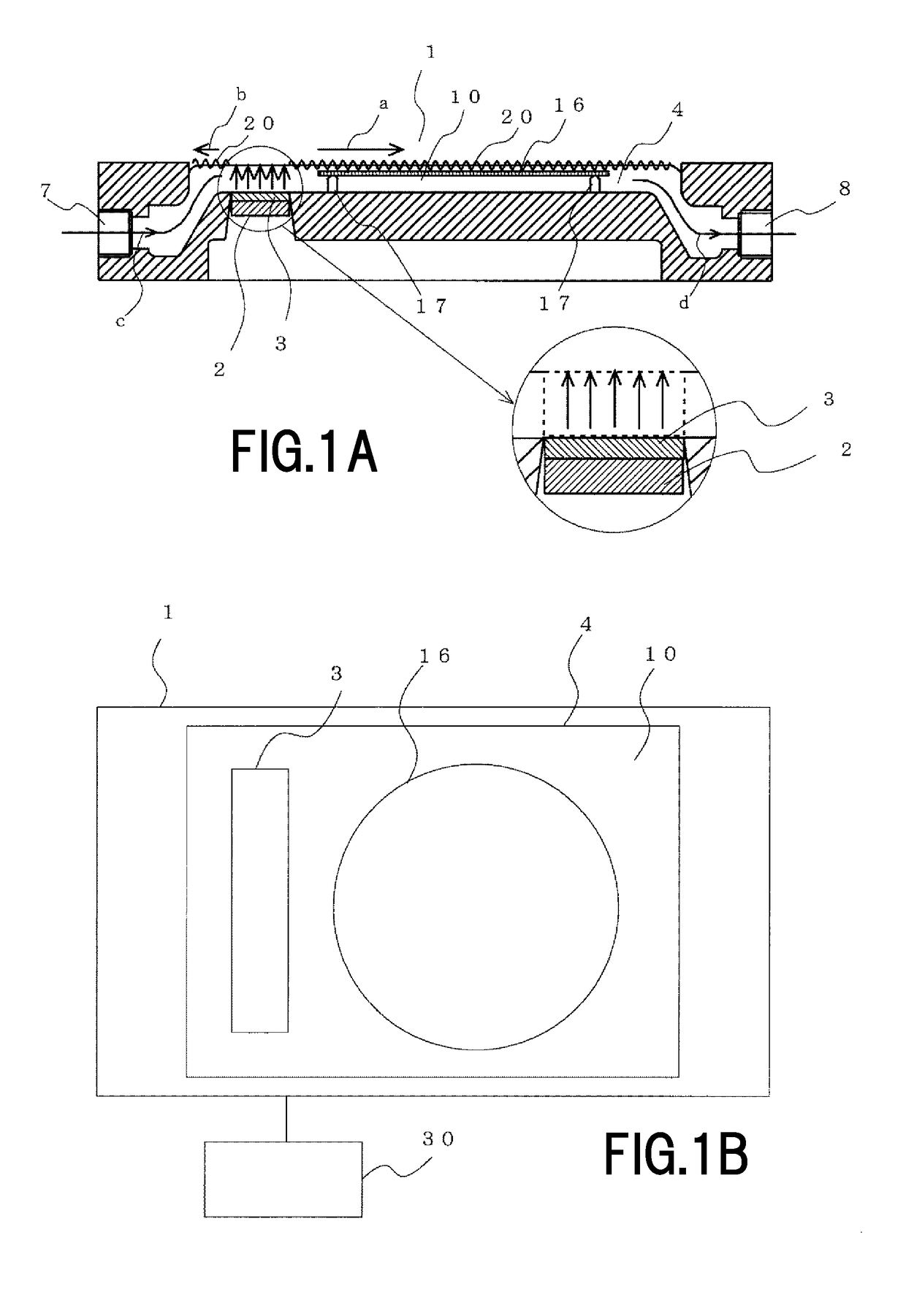

ActiveCN103229279AAvoid damageImprove cleanlinessSemiconductor/solid-state device manufacturingCleaning using liquidsUltrasonic sensorMegasonic cleaning

Provided is an ultrasonic cleaning device and ultrasonic cleaning method that can suppress occurrences of damage to substrates being cleaned and, additionally, can carry out cleaning with a high degree of cleanliness for substrates and the like, which have high degrees of precision and are used by the electronics industry and the like. An article (16) being cleaned is held so as to be positioned in the proximity of below the surface of a cleaning fluid outside of a region (ultrasonic exposure region) formed by perpendicular lines extending from an oscillation surface of an ultrasonic transducer (2) to the fluid surface. Capillary waves (20) are formed on the surface of the cleaning fluid by ultrasonic waves, and without directly exposing the article being cleaned (16) to the ultrasonic waves, microparticle contamination on the article being cleaned (16) is detached by the sound pressure made by the capillary waves (20), thus suppressing occurrences of damage to the substrate being cleaned.

Owner:KAIJOO KK

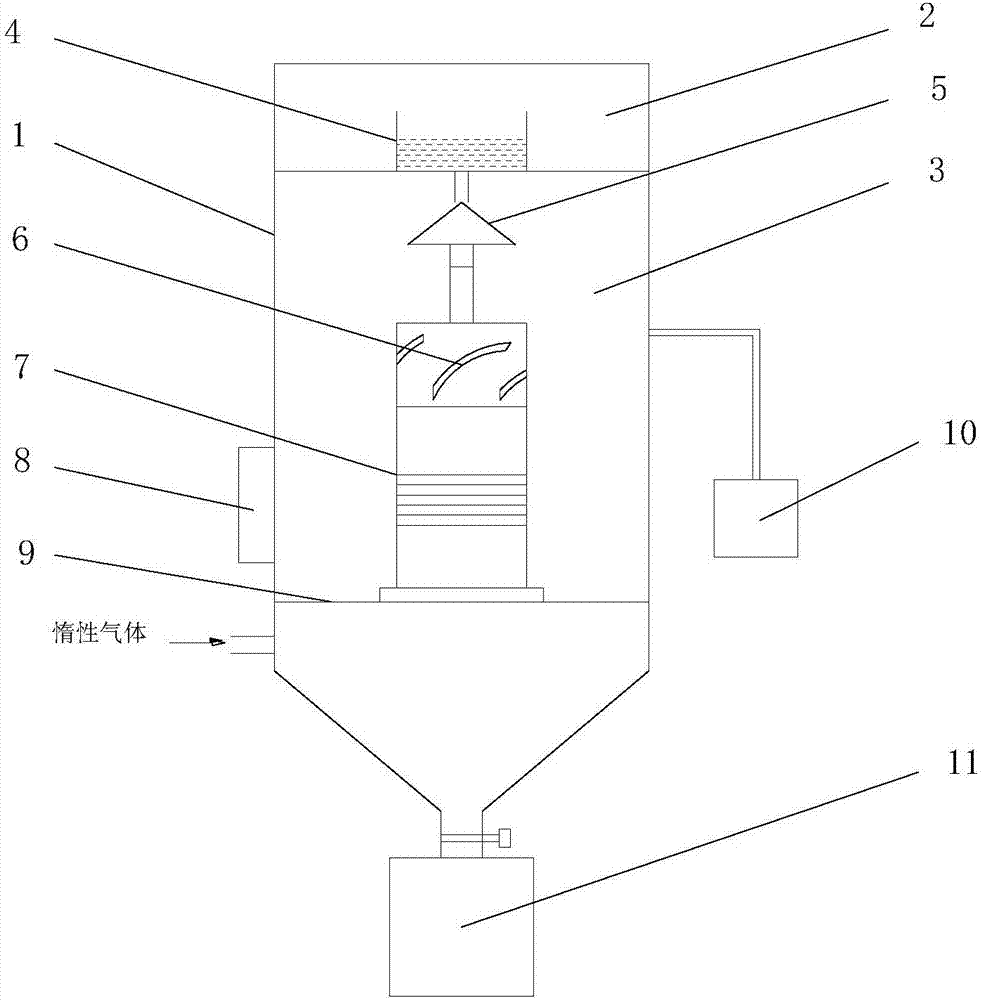

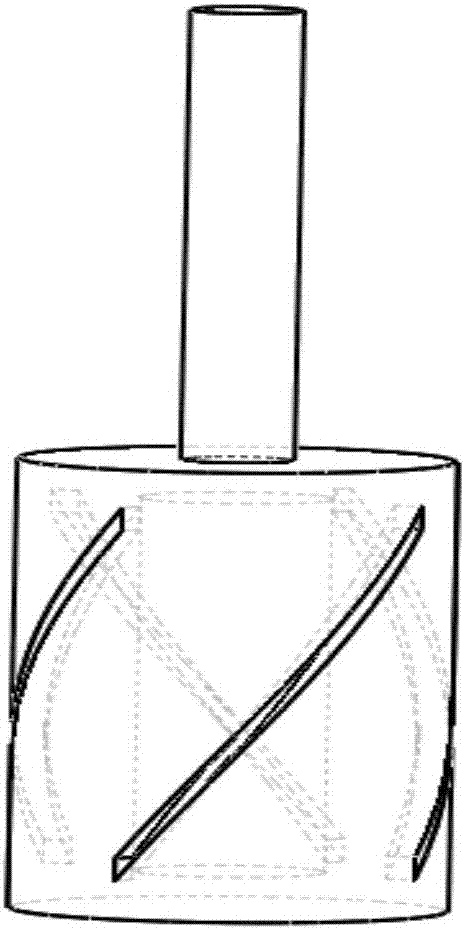

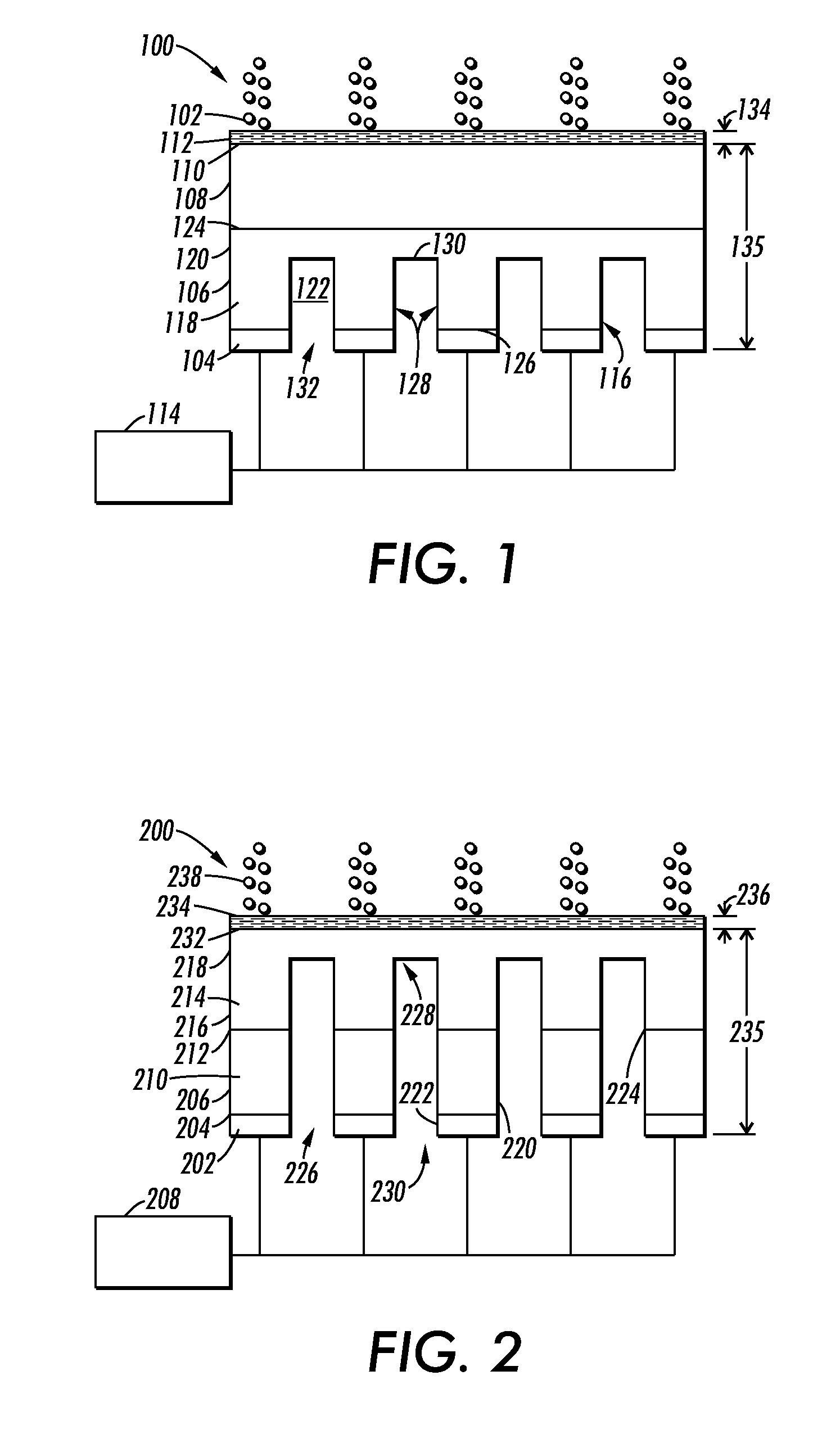

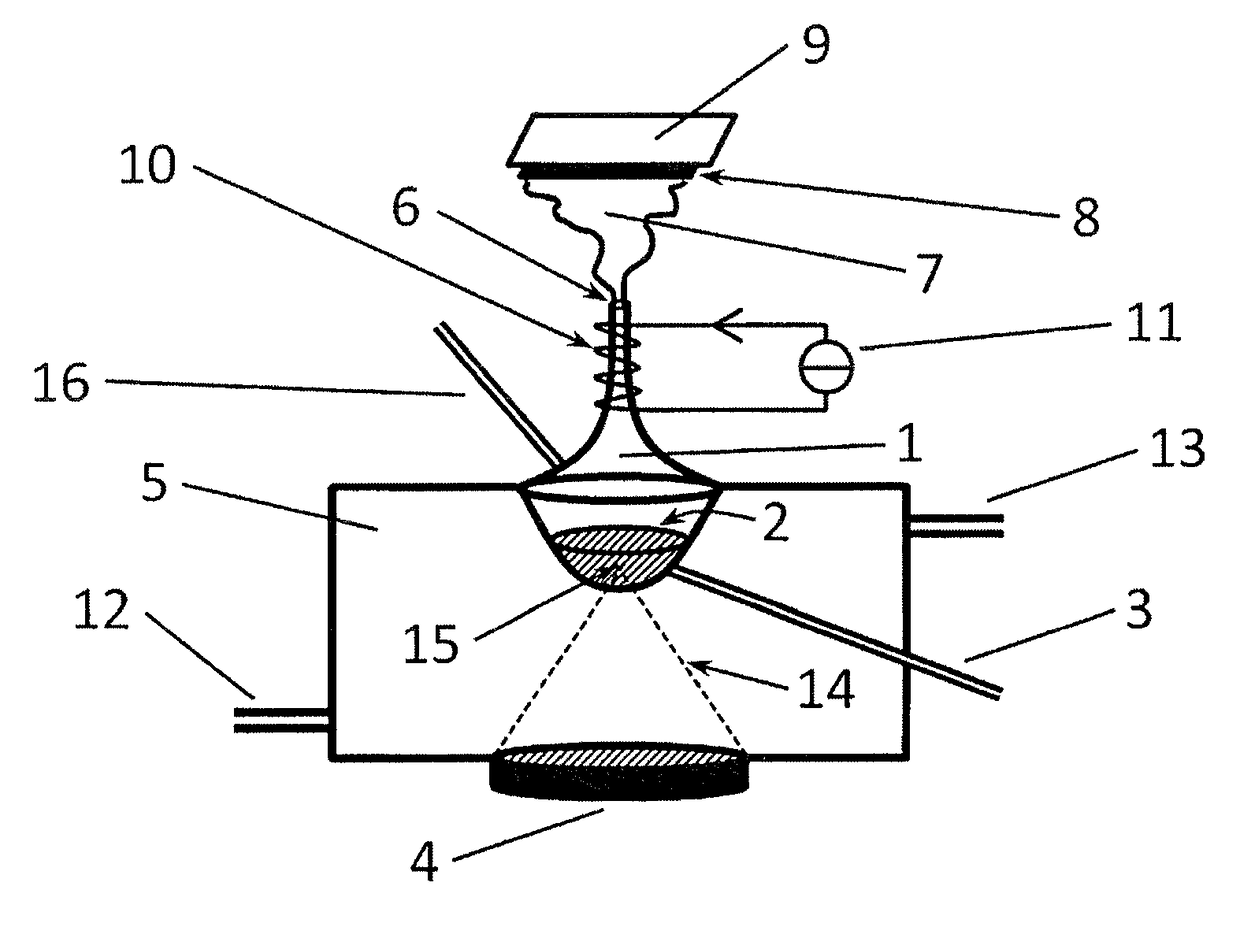

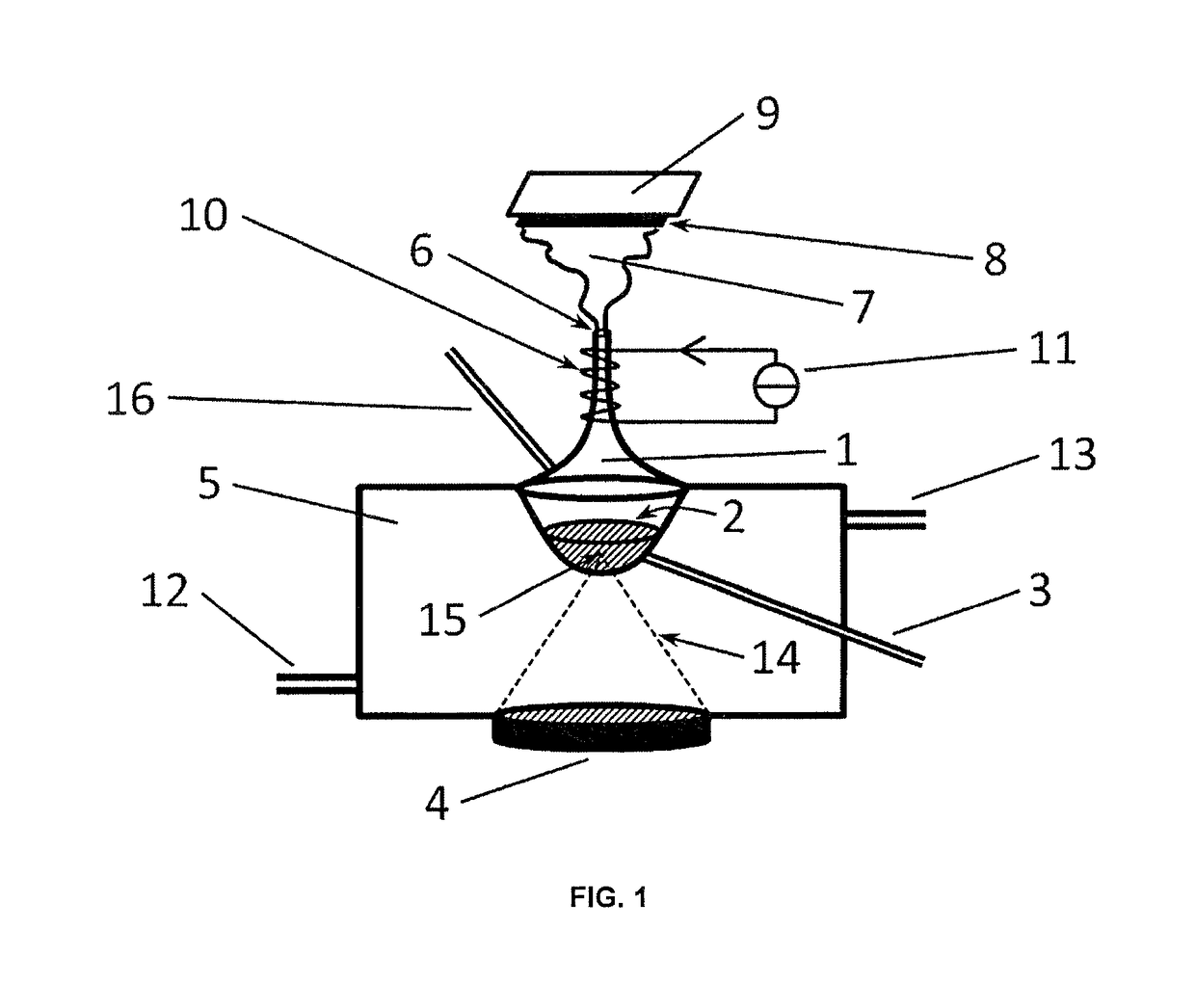

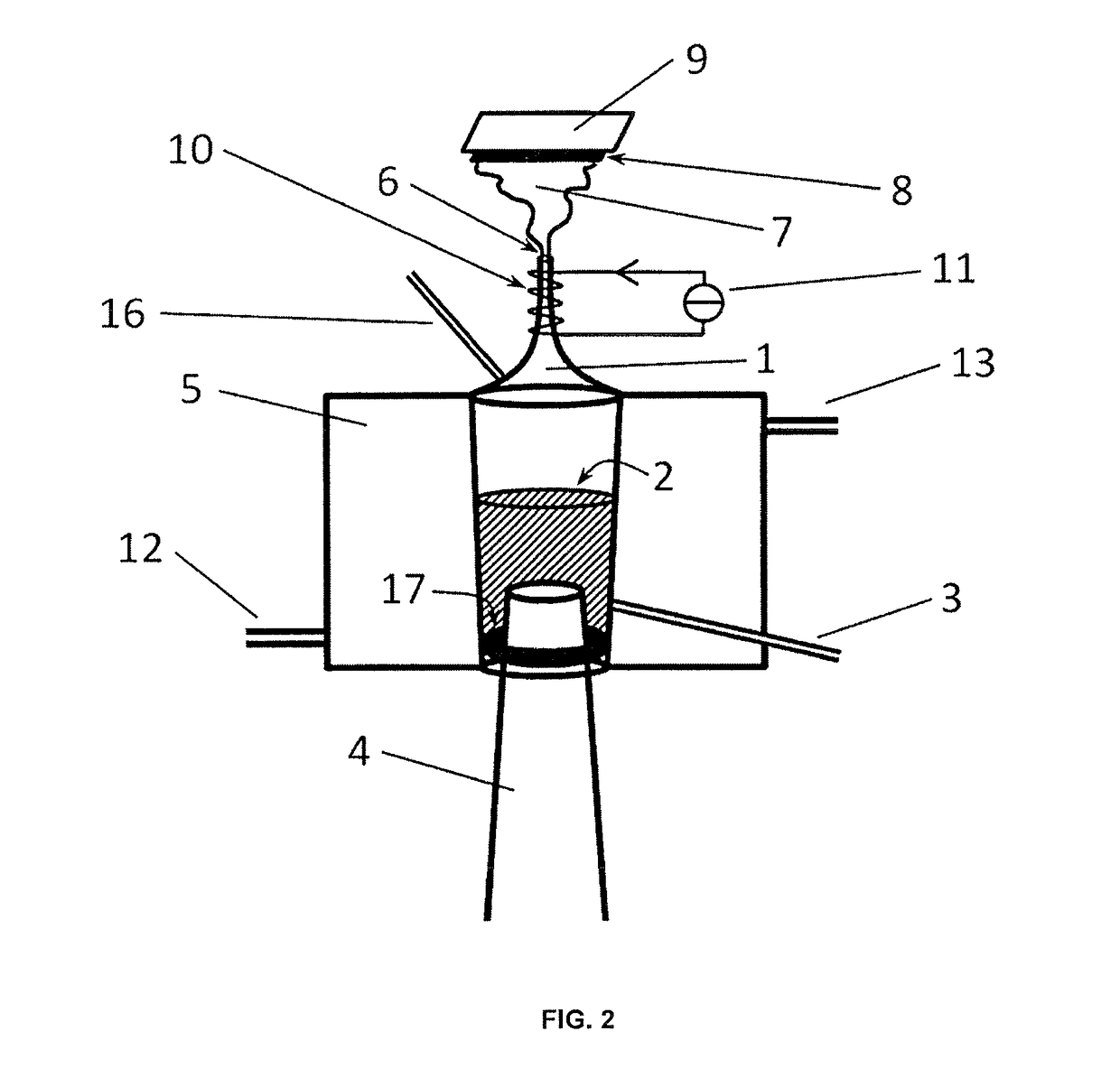

Method and device for polymerizing a composition comprising hydridosilanes and subsequently using the polymers to produce silicon-containing layers

ActiveUS20160297997A1Liquid/solution decomposition chemical coatingSemiconductor devicesNoble gasCavitation

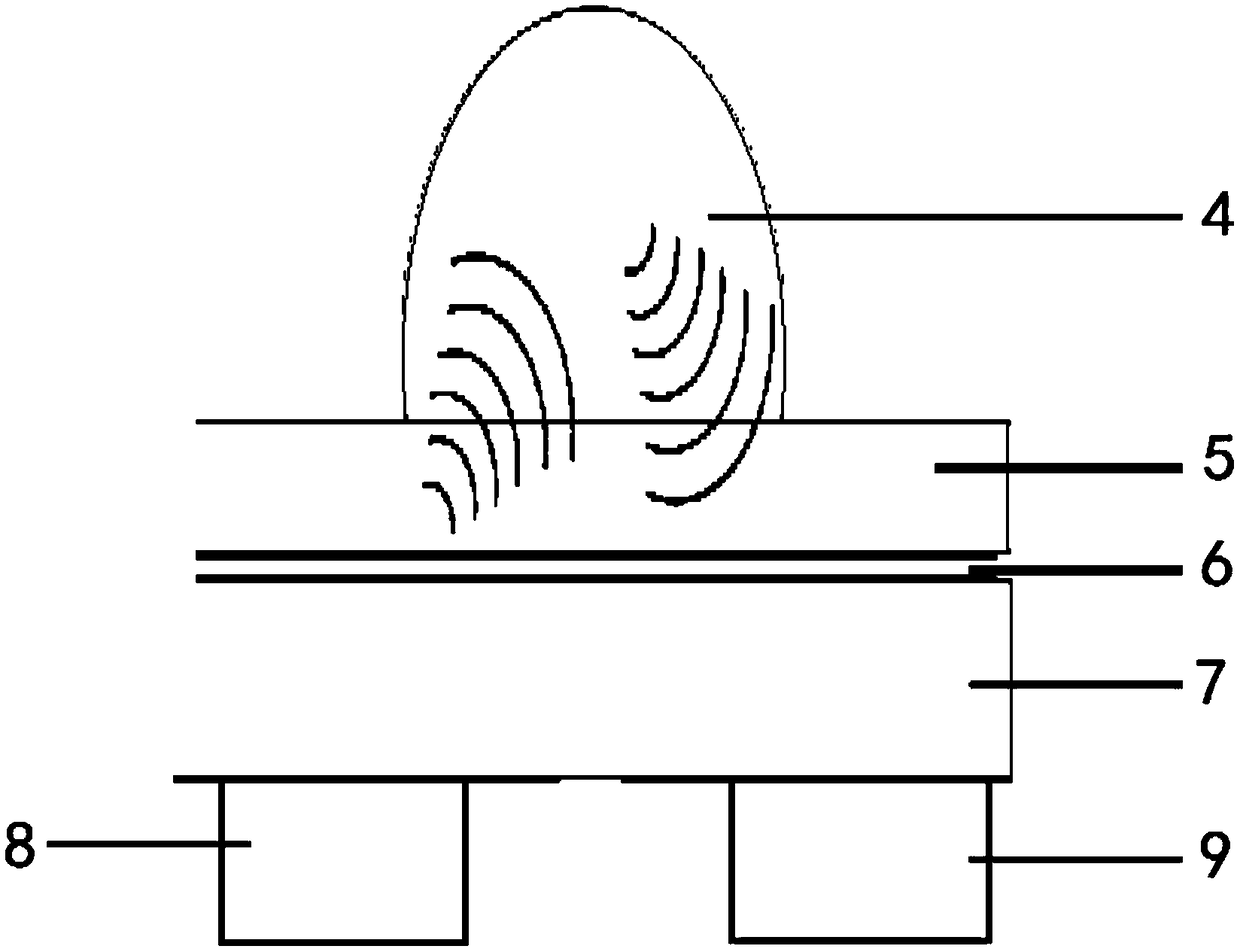

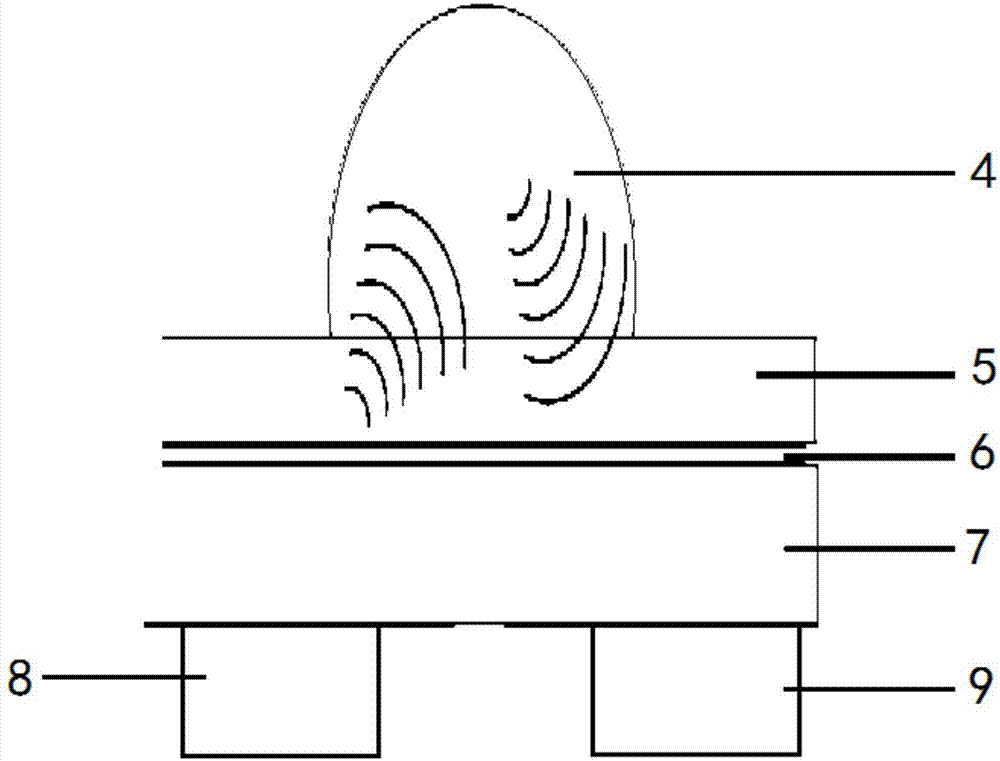

A method for polymerizing a composition including hydridosilanes and subsequently using the polymers to produce silicon containing layers, comprising the following steps: a) providing a substrate; b) providing a composition including at least one hydridosilane that is dissolved in at least one organic and / or inorganic solvent, or including at least one hydridosilane that is already present in liquid form without solvent, wherein the hydridosilanes comprise at least one linear and / or one branched hydridosilane of the general formula SinH2n+2, where n≧3, and / or a cyclic hydridosilane of the general formula SinH2n, where n≧3; c) polymerizing the composition from step b) by way of acoustic cavitation; and d) coating the surface of the substrate with reaction products from step c). A device for polymerizing a composition including hydridosilanes and subsequently using the polymers to produce silicon containing layers, comprising at least one reaction vessel (1) containing a composition that includes at least one hydridosilane that is dissolved in at least one organic and / or inorganic solvent, or at least one hydridosilane that is already present in liquid form without solvent, wherein the hydridosilanes comprise at least one linear and / or branched hydridosilane of the general formula SinH2n+2, where n≧3, and / or a cyclic hydridosilane of the general formula SinH2n, where n≧3, and / or containing the abovementioned hydridosilane solution or the pure liquid hydridosilane, to which at least monosilane and / or disilane and / or boron containing dopant and / or phosphorus containing dopant and / or a noble gas from the group Ar, He and / or nanoparticles and / or a polymerization initiator and / or a catalyst and / or surface tension modifying agents can be added, and an ultrasound source and / or a sound transducer (4) for generating acoustic cavitation and / or capillary waves, wherein the reaction vessel (1) has at least one closable opening (6), the substrate (8) to be coated is disposed opposite the opening (6), and the substrate (8) comprises a heating source (9) on the surface that faces away from the coating surface.

Owner:FORSCHUNGSZENTRUM JILICH GMBH

Ultrasonic cleaning apparatus and ultrasonic cleaning method

ActiveUS20130312787A1Damage can be be suppressedImprove cleanlinessSemiconductor/solid-state device manufacturingElectrostatic cleaningUltrasonic radiationMegasonic cleaning

There are provided an ultrasonic cleaning apparatus and an ultrasonic cleaning method capable of suppressing occurrence of damage on a substrate to be cleaned and capable of performing cleaning at a high cleaning level for highly precise substrates and the like used in an electronics industry. Occurrence of damage on the substrate to be cleaned is suppressed by holding an object to be cleaned so as to be positioned out of a region where perpendiculars extend from an oscillating surface of an ultrasonic transducer to a liquid surface (an ultrasonic-irradiated region) under and in the vicinity of the liquid surface of a cleaning solution, exciting a capillary wave on a surface of the cleaning solution by an ultrasonic wave, and separating particulate contamination of the object to be cleaned by an acoustic pressure generated by the capillary wave without irradiating the object to be cleaned directly with the ultrasonic wave.

Owner:KAIJOO KK

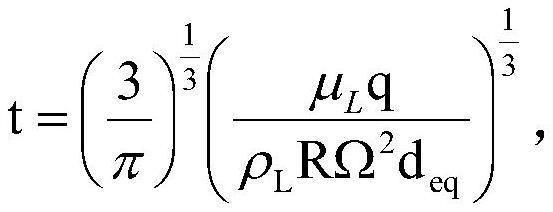

Large-amplitude ultrasonic spherical metal powder preparing device and method

ActiveCN107876787AFine granularityGood sphericityTransportation and packagingMetal-working apparatusVibration amplitudeLiquid layer

The invention relates to a large-amplitude ultrasonic spherical metal powder preparing device and method, and belongs to the technical field of metal powder preparing. The device comprises a tank body, an inner cavity of the tank body is divided into a fusion chamber and an atomizing chamber from top to bottom, and a support, an energy converter arranged on the support and connected with an ultrasonic generator, a slotting amplitude-change pole arranged along a longitudinal vibration output shaft of the energy converter and an umbrella-shaped tool head connected with the output end of the slotting amplitude-change pole are arranged in the atomizing chamber; the energy converter is stimulated under external voltage to generate weak mechanical vibration, the slotting amplitude-change pole can amplify particle displacement of the mechanical vibration, the large vibration amplitude can be obtained, a metal thin liquid layer formed on the umbrella top of the umbrella-shaped tool head arouses capillary waves under the supersonic vibration effect, when the vibration amplitude of the vibration face is larger, liquid drops fly out from wave crests to form met frog, the particle size of theprepared metal powder is small, and the degree of sphericity is good.

Owner:SHAANXI NORMAL UNIV

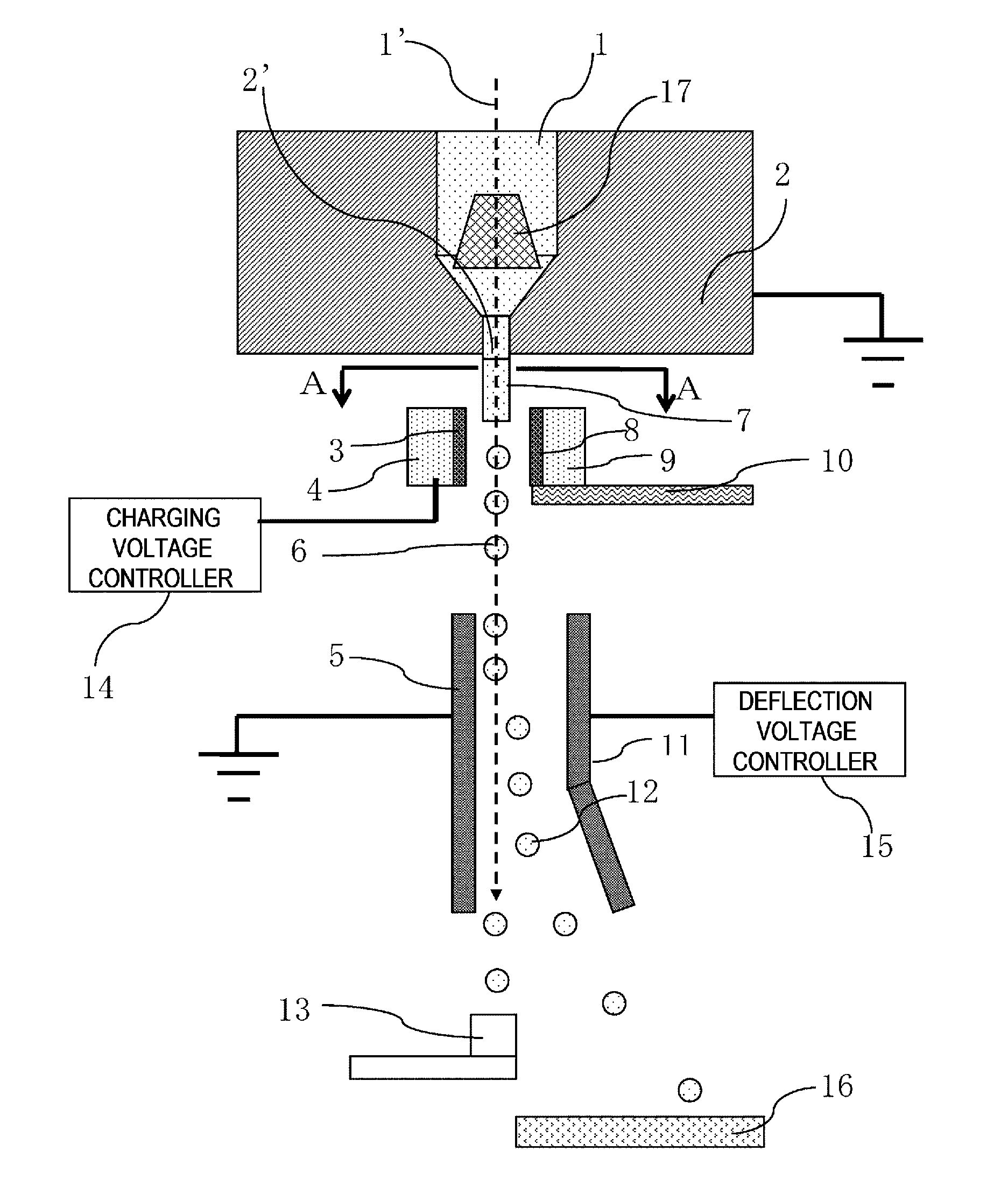

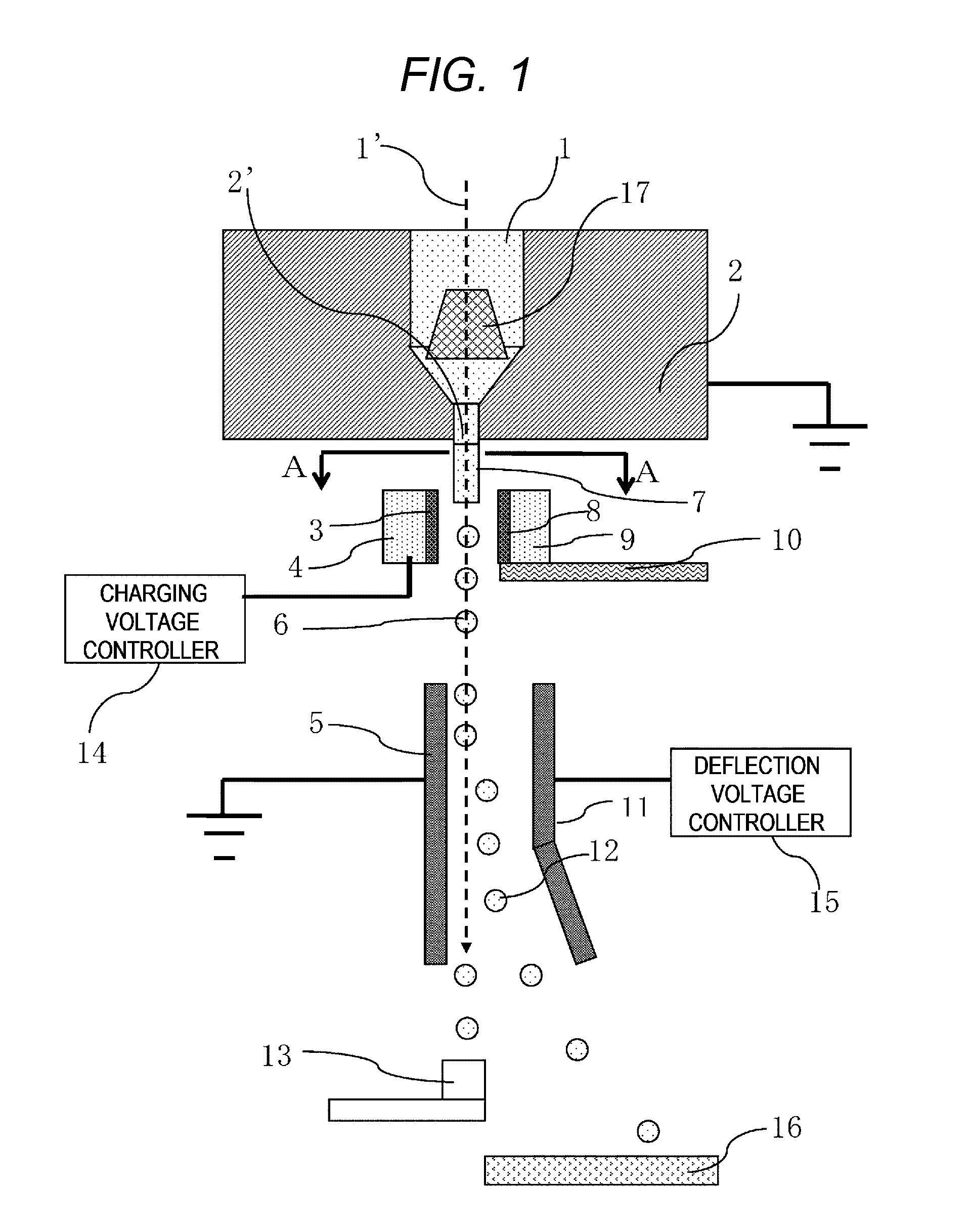

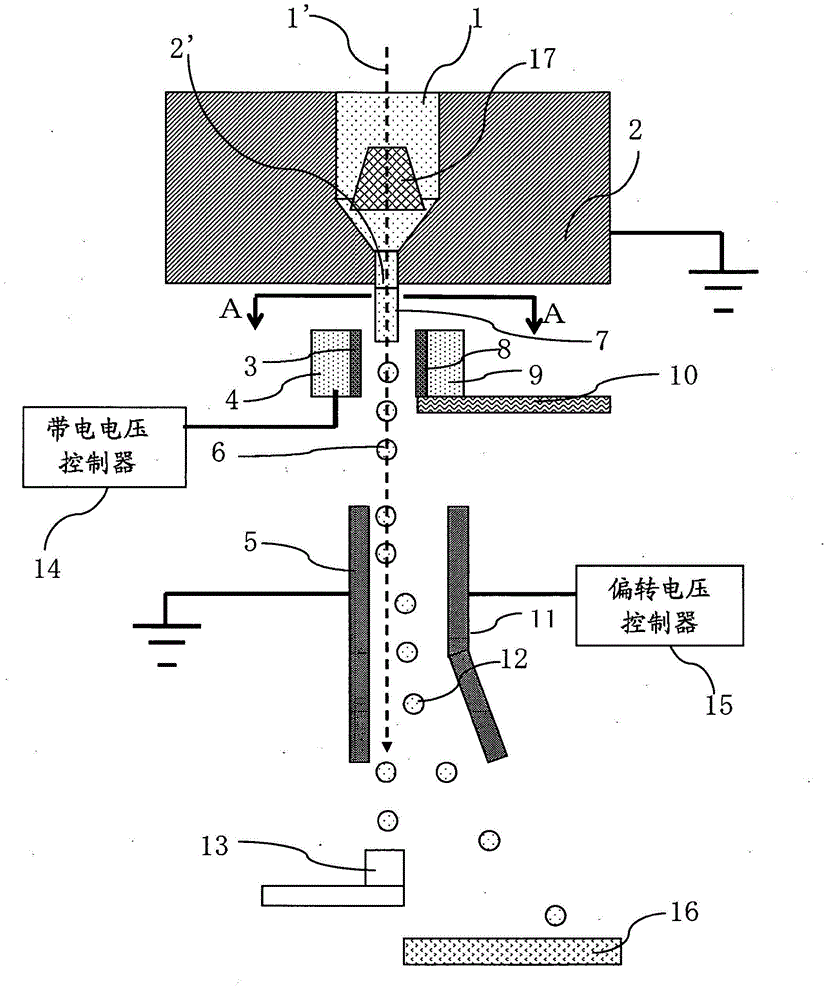

Ink Jet Recording Apparatus

An ink jet recording apparatus that can perform high velocity printing without printing distortion is realized. In a continuous discharge type ink jet recording apparatus, a unit that suppresses a velocity in the vicinity of a center axis is disposed in a unit that injects ink droplets in which because a velocity in an outer periphery is higher than that in a center of a discharged liquid column, a velocity on a surface of the liquid column becomes quickly high, and a capillary wave that propagates on a surface of the liquid column in a travel direction is quickly amplified because the velocity becomes quickly a velocity suitable for droplet breakup, the droplet breakup is quickly generated, and the droplet breakup is surely generated within a charging electrode located next to the nozzle. As a result, an ink jet recording apparatus stable in printing quality performance is provided.

Owner:HITACHI IND EQUIP SYST CO LTD

Ink jet recording apparatus

Owner:HITACHI IND EQUIP SYST CO LTD

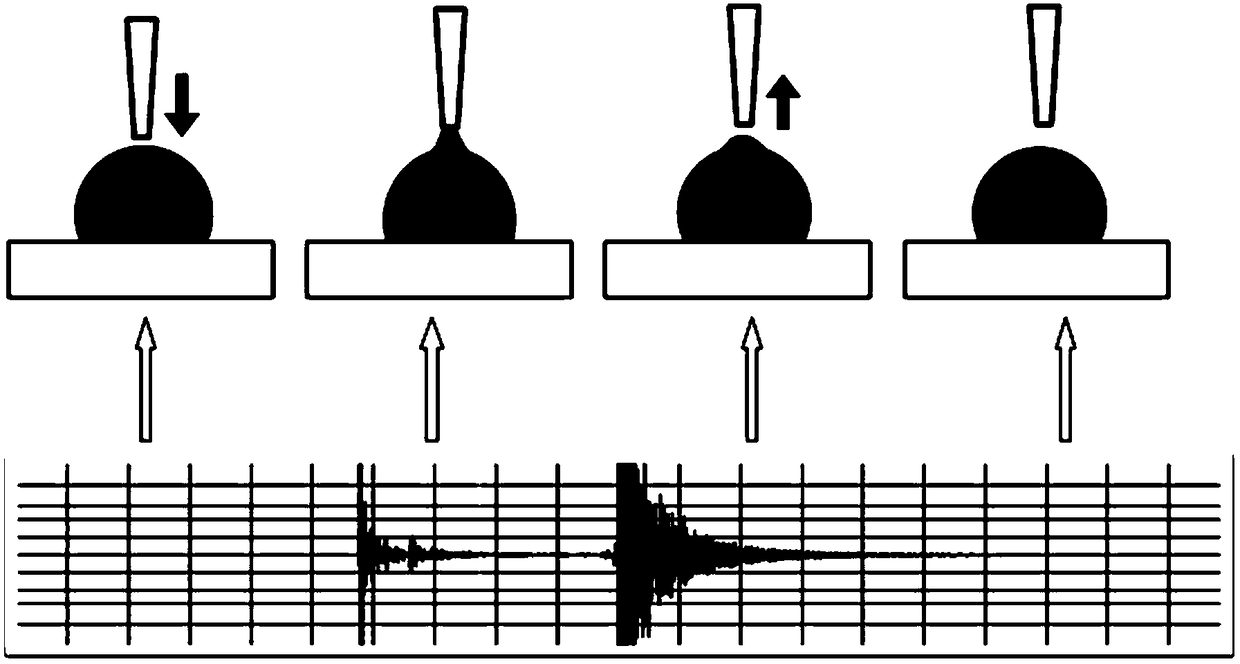

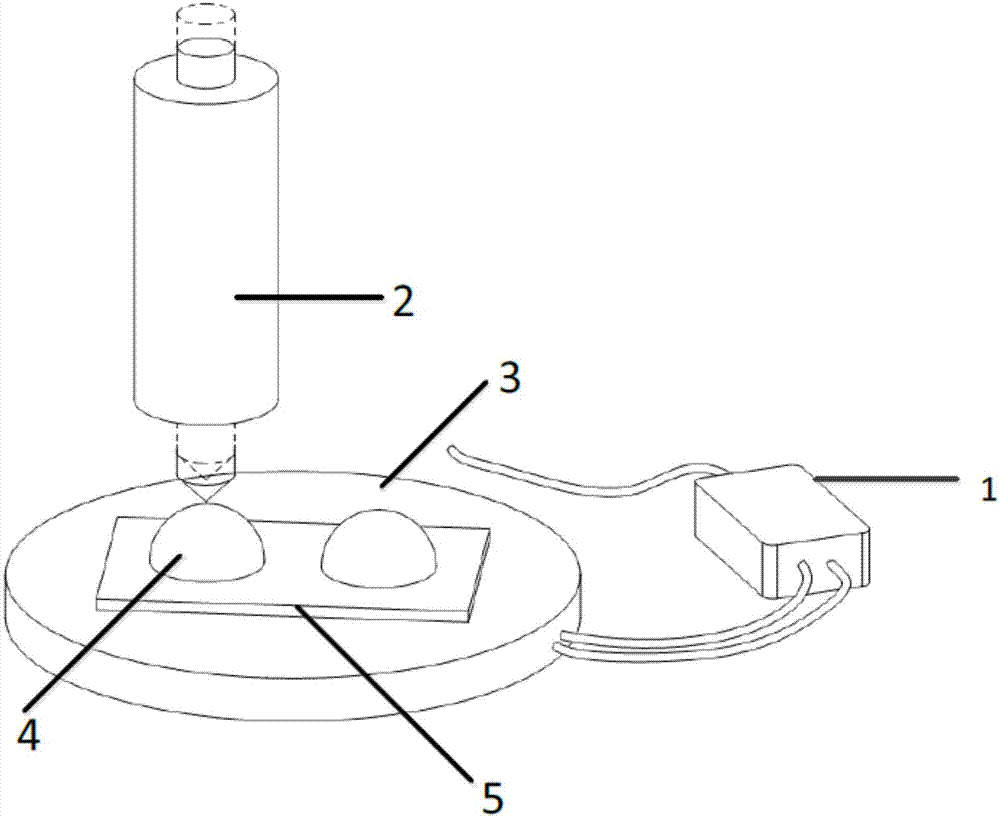

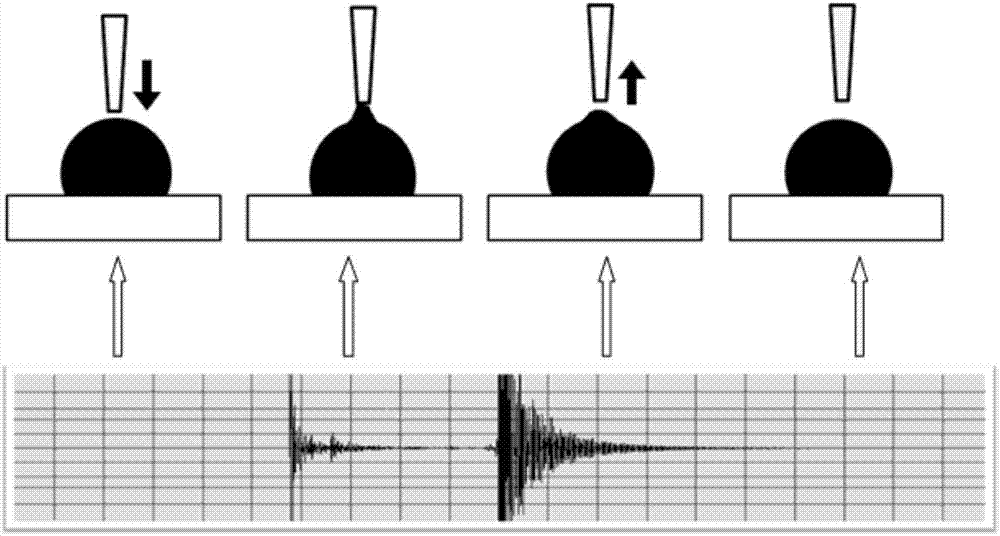

Liquid surface tension testing method based on mechanical vibration of liquid droplet

ActiveCN108318384AReduce dosageGood value for moneySurface tension analysisFrequency measurementsUltrasound doppler

The invention relates to a liquid surface tension testing method based on mechanical vibration of a liquid droplet. The method specifically comprises the following steps: placing a hydrophobic substrate on a Doppler ultrasonic probe, and generating a liquid droplet on the hydrophobic substrate; vibrating a triggering device to freely vibrate the liquid droplet; converting free vibration of capillary waves on the surface of the liquid droplet into an ultrasonic Doppler frequency shift signal through the ultrasonic probe by using a non-focusing continuous wave Doppler method, and amplifying theultrasonic Doppler frequency shift signal; acquiring a free vibration characteristic diagram of the liquid droplet from the ultrasonic Doppler frequency shift signal by using a computer signal processing module, performing Fourier transform so as to obtain a vibration frequency characteristic diagram, analyzing the vibration frequency characteristic diagram, and reading frequency of a second harmonic generation peak; by taking the reciprocal of the mass of the liquid droplet as a transverse coordinate, and the square of the frequency of the second harmonic generation peak as a longitudinal coordinate, drawing diagrams, fitting straight lines, calculating a straight slope, and further calculating the surface tension of the liquid droplet. The method based on ultrasonic Doppler frequency shifting is capable of carrying out frequency measurement on ultrasonic signals, and has the advantages of reagent conservation, high performance cost ratios and portability.

Owner:TONGJI UNIV

Liquid viscosity test method based on liquid drop mechanical vibration

The invention relates to a liquid viscosity test method based on liquid drop mechanical vibration. The method concretely comprises the following steps that a hydrophobic substrate is placed on a ultrasonic probe of a Doppler ultrasonic instrument; liquid drops are generated on the hydrophobic substrate through a microinjector; the liquid drops are vibrated through a vibration triggering device with an automatic rebounding function; then, the vibration triggering device rebounds; the liquid drops generate free vibration; the free vibration of liquid drop surface capillary waves is converted into ultrasonic wave Doppler frequency shift signals by a non-focusing continuous wave Doppler method through the ultrasound probe, and the signals are amplified; a computer signal processing module collects and processes the Doppler frequency shift signals to obtain a liquid drop free vibration characteristic pattern; the free vibration characteristic pattern is subjected to fitting to obtain the decay rate of the liquid drop amplitude along with the time; further, the liquid viscosity is obtained through calculation. When the method is used for measuring the liquid drop viscosity, the responsespeed is high; the application range is wide; the reliability is high; the equipment is portable; the cost performance is high; the reagent consumption is little.

Owner:TONGJI UNIV

Ultrasonic spray-forming method

The invention relates to an ultrasonic spray-forming method, which is technically characterized in that: a novel molten metal atomization and deposition manner is provided according to the fundamental principle that molten metal flow is atomized into fine grains by spray-forming; and the fundamental principle of the manner is that: the molten metal flows on the surface of a tool head which vibrates at ultrasonic frequency to form a thin liquid layer; surface tension waves are surged under the action of ultrasonic vibration; liquid drops depart from wave crests when the amplitude of a vibrating surface reaches a certain value; the liquid drops rapidly hit a deposition plate or a collector and are fast solidified under the drive of high-speed inert gas; and metal blanks with required shapescan be manufactured through controlling the position and the angle of a receiver by using different shapes of collectors. The crystal grain of a microstructure of the manufactured blanks is finer.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

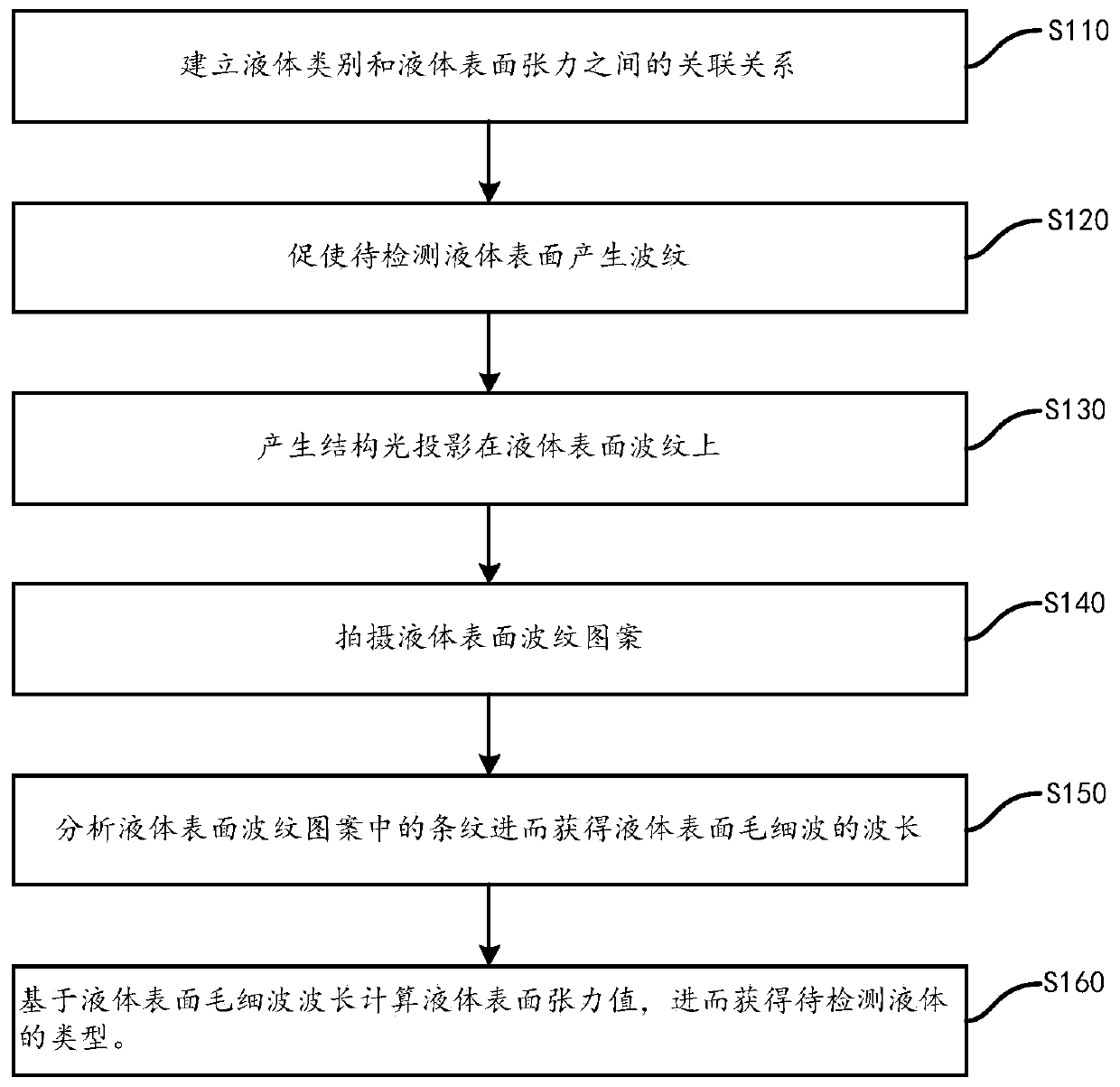

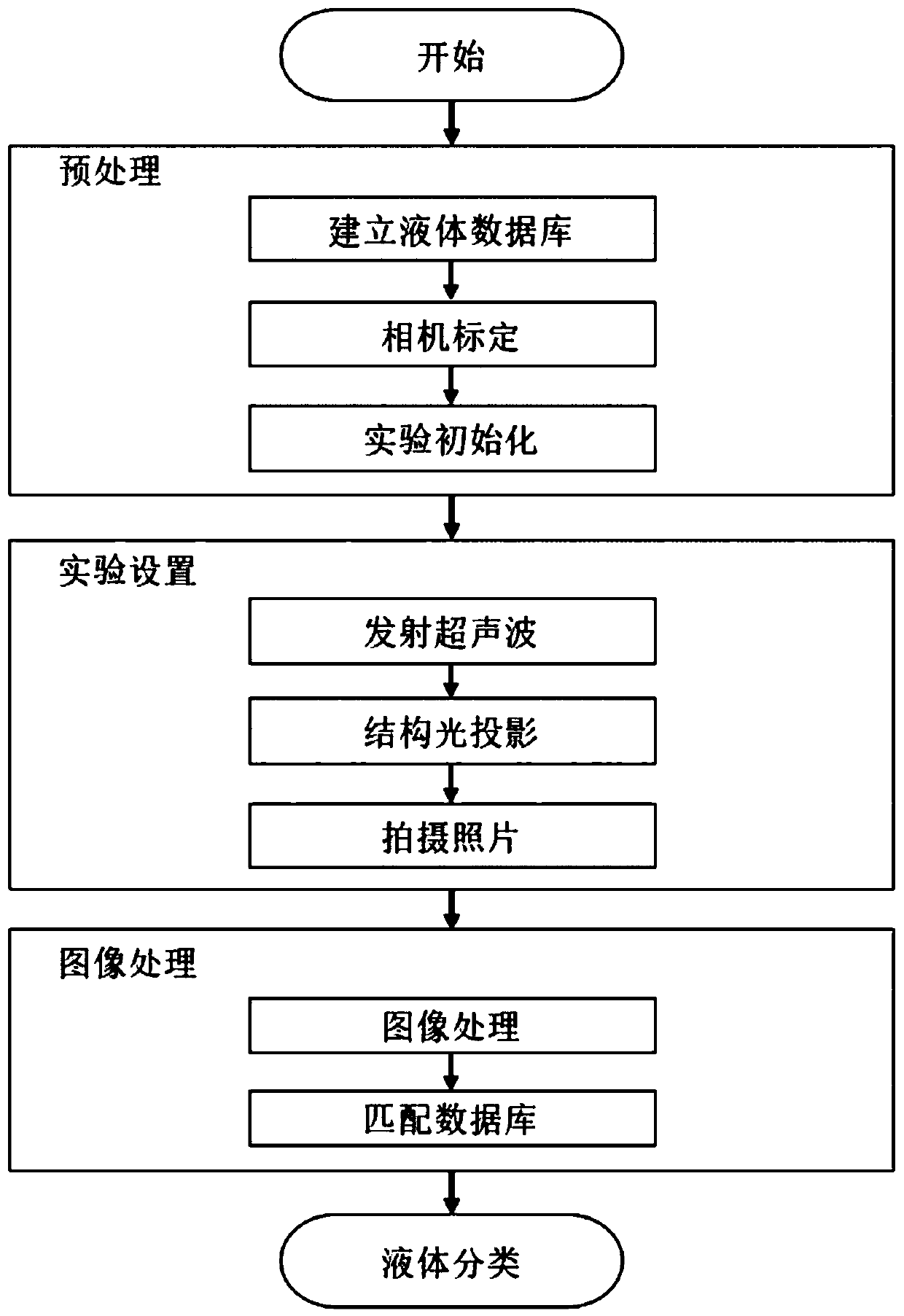

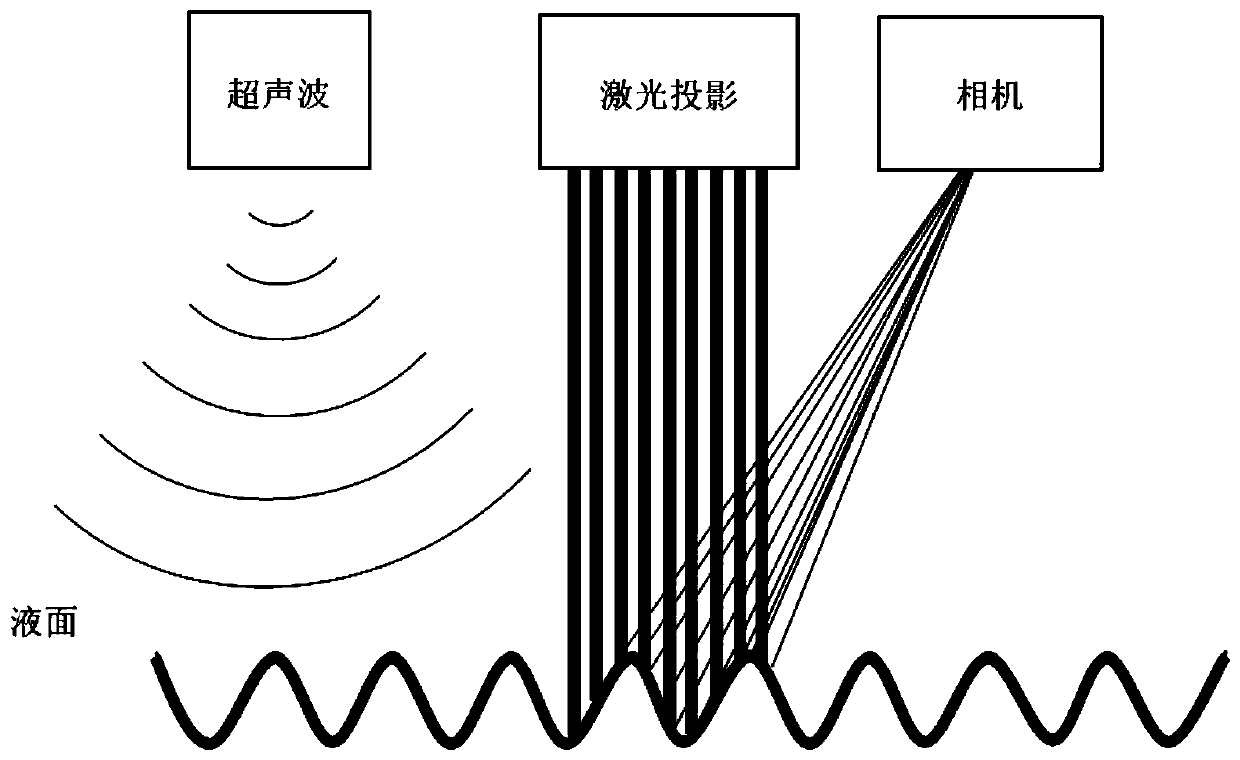

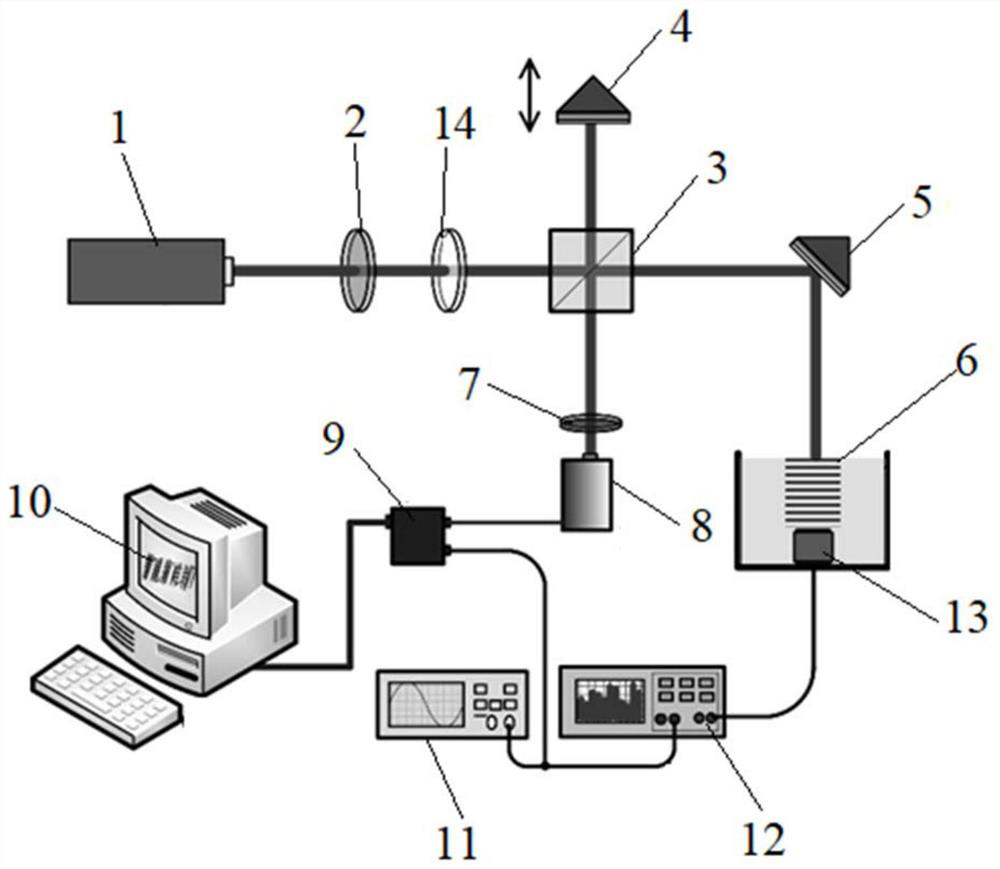

Liquid detection method and system based on measurement of surface capillary waves with structured light

ActiveCN110749528AHigh precisionImprove accuracySurface tension analysisSurface tension forceLiquid surfaces

The invention provides a liquid detection method and a system based on measurement of surface capillary waves with structured light. The liquid detection method comprises steps of generating surface waves of liquid to be measured and projecting the predetermined structured light onto the surface of the liquid to be measured; analyzing actual height change represented by stripes of the surface waves of the liquid to be measured to obtain a wavelength of the surface capillary waves of the liquid to be measured; calculating surface tension of the liquid to be measured based on the wavelength of the surface capillary waves, and obtaining a type of the liquid to be measured according to an established relationship between the liquid type and the surface tension of the liquid. The method and thesystem of the present invention use the characteristics of surface capillary waves of the liquid to propose a high-precision, low-cost, and universal detection mechanism.

Owner:SHENZHEN UNIV

Method of ionizing a liquid and an electrostatic colloid thruster implementing such a method

ActiveUS7872848B2Spraying power supplyDecorative surface effectsSpacecraft propulsionColloid thruster

A method of ionizing a liquid is disclosed herein. The method includes the steps of dispensing an electrically conductive liquid onto an electrically conductive membrane so as to form a liquid film on the surface of the membrane, applying an electrical charge to the liquid film on the membrane, generating ultrasonic waves to vibrate the membrane so as to induce capillary waves in the liquid film, and electrostatically attracting the electrically charged crests in the capillary waves so that electrically charged droplets are extracted from the capillary waves and accelerated therefrom for emission. The method is generally utile in various applications including, for example, spacecraft propulsion, paint spray techniques, semiconductor fabrication, biomedical processes, and the like. In addition to the above-described method, an electrostatic colloid thruster for implementing the method is disclosed herein as well.

Owner:THE BOEING CO

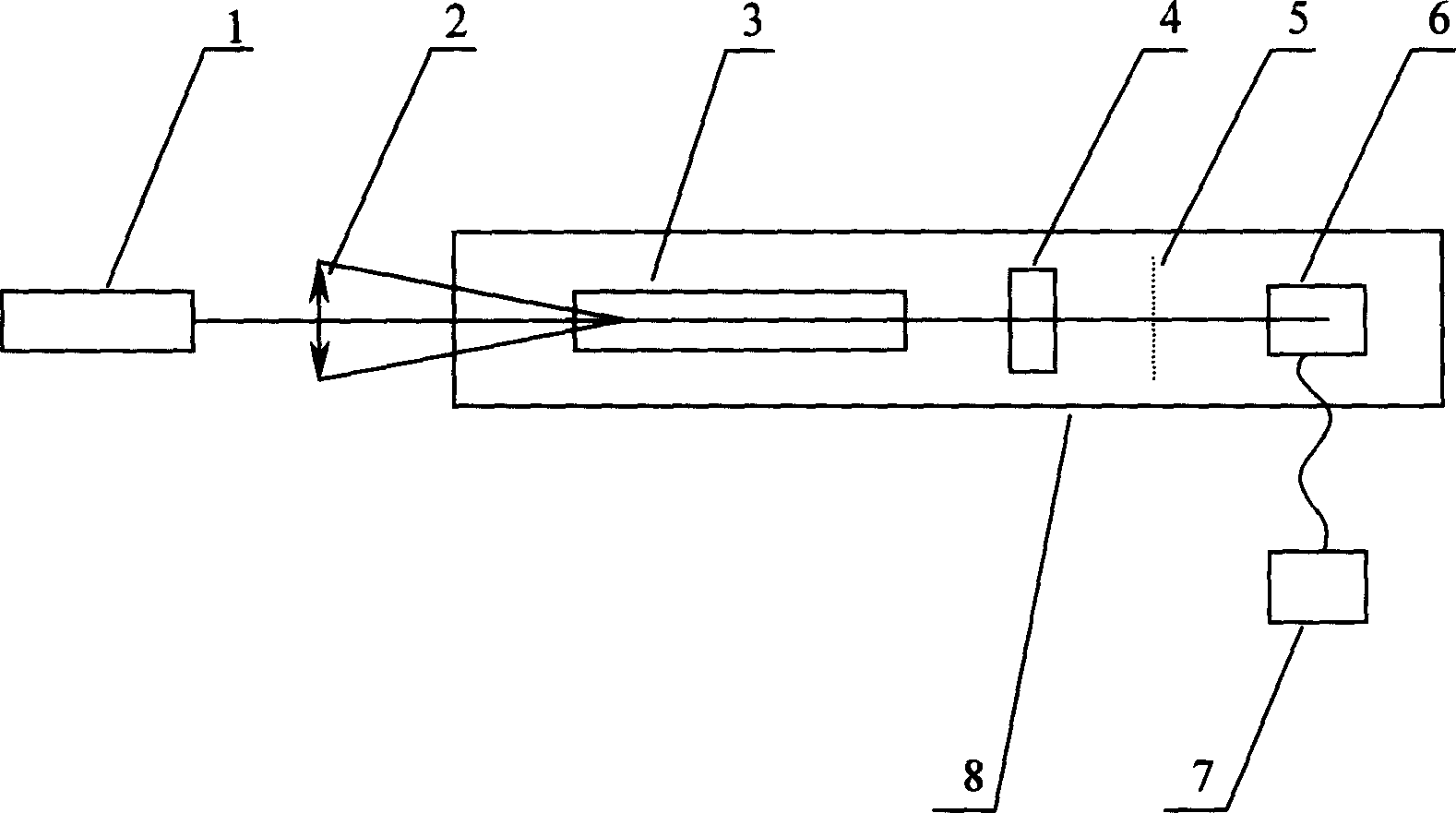

High subharmonic soft x-ray lining microscope

InactiveCN1564046AHigh-resolutionImprove spatial coherenceMicroscopesHigher order harmonicsVacuum chamber

The phase contrast microscope includes femtosecond laser, and convergent lens, hollow capillary wave-guide, sample cell, zone plate and detector arranged in sequence on optical path. Capillary wave-guide, sample cell, zone plate and detector are setup inside vacuum chamber. The detector though wire is connected to computer outside the chamber. Laser through convergent lens is focused on capillary wave-guide, causing ionization of gas in capillary wave-guide to generate high order harmonic soft X-ray. The said soft X ray irradiates sample to be tested inside sample room. Then zone plate between sample room and detector forms a magnified image on the detector, which sends phase contrast image to computer for processing. The device possesses higher resolution and real time processing capability, being applicable to study ultra quick physical process of superfine structure.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

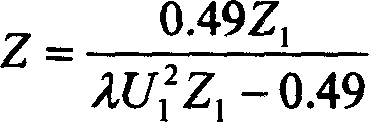

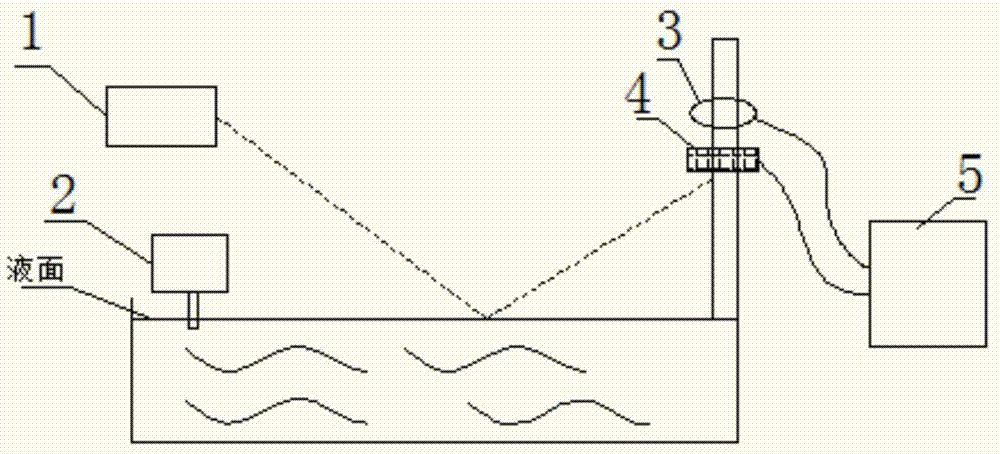

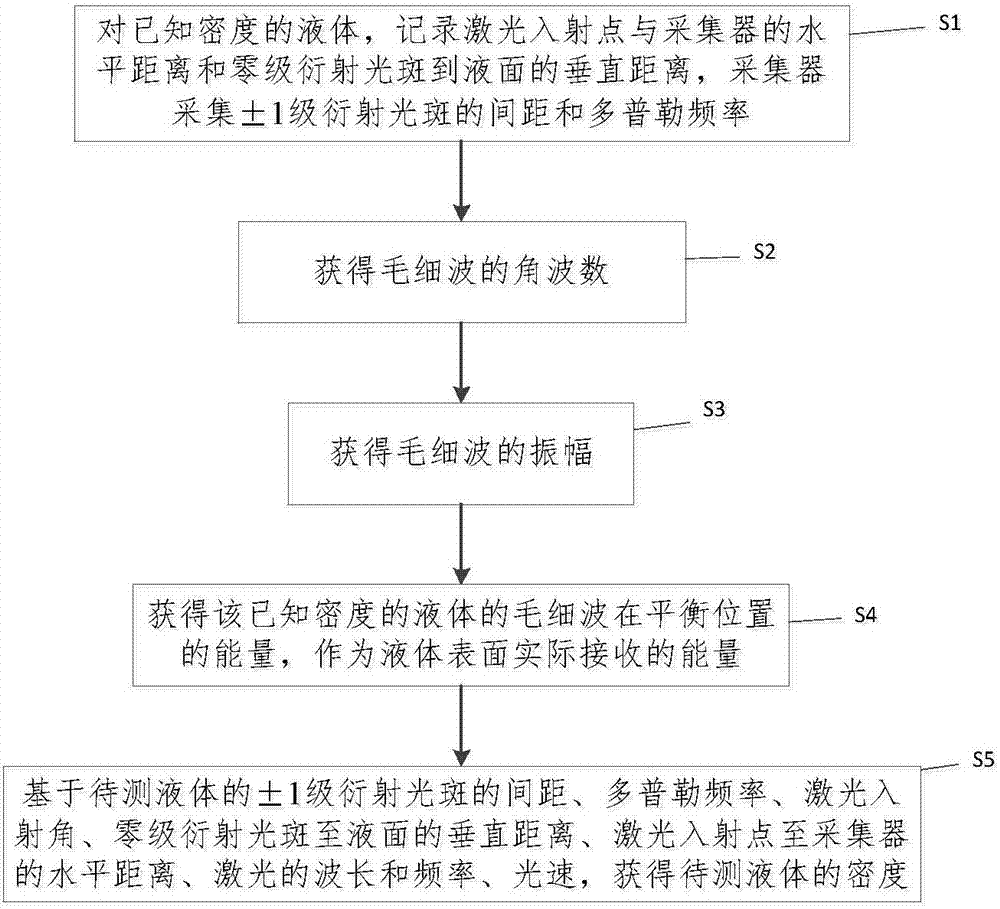

System, method and application for detecting liquid density

ActiveCN107063923AReduce the impactImprove stabilitySpecific gravity measurementGratingLiquid density

The invention provides a system, method and application for detecting liquid density. The system comprises a laser generator, a capillary wave exciter, a collector, a geometrical parameter collector and a data processing device, wherein the laser generator is used for jetting a laser light in a certain wavelength to a liquid surface at a certain angle; the capillary wave exciter is used for generating a capillary wave on the liquid surface; the collector is used for collecting Doppler frequency and an interval of + / - level diffraction spot corresponding to the present liquid; the geometrical parameter collector is used for collecting the wavelength of the laser light, the frequency of the laser light, the incidence angle of the laser light, the frequency of the capillary wave exciter, a vertical distance from the zero level diffraction spot to the liquid surface and a horizontal distance from the incidence point of the laser light to the collector; and the data processing device is used for receiving the data collected by the collector and the geometrical parameter collector and calculating the liquid density. On the basis of a Doppler measuring principle and an optical grating diffraction principle, the system can achieve the effect of non-contact detection for liquid density, can realize convenient and quick real-time detection, is high in operation efficiency, can promote the detection efficiency and has continuous detection capacity.

Owner:CHINA AGRI UNIV

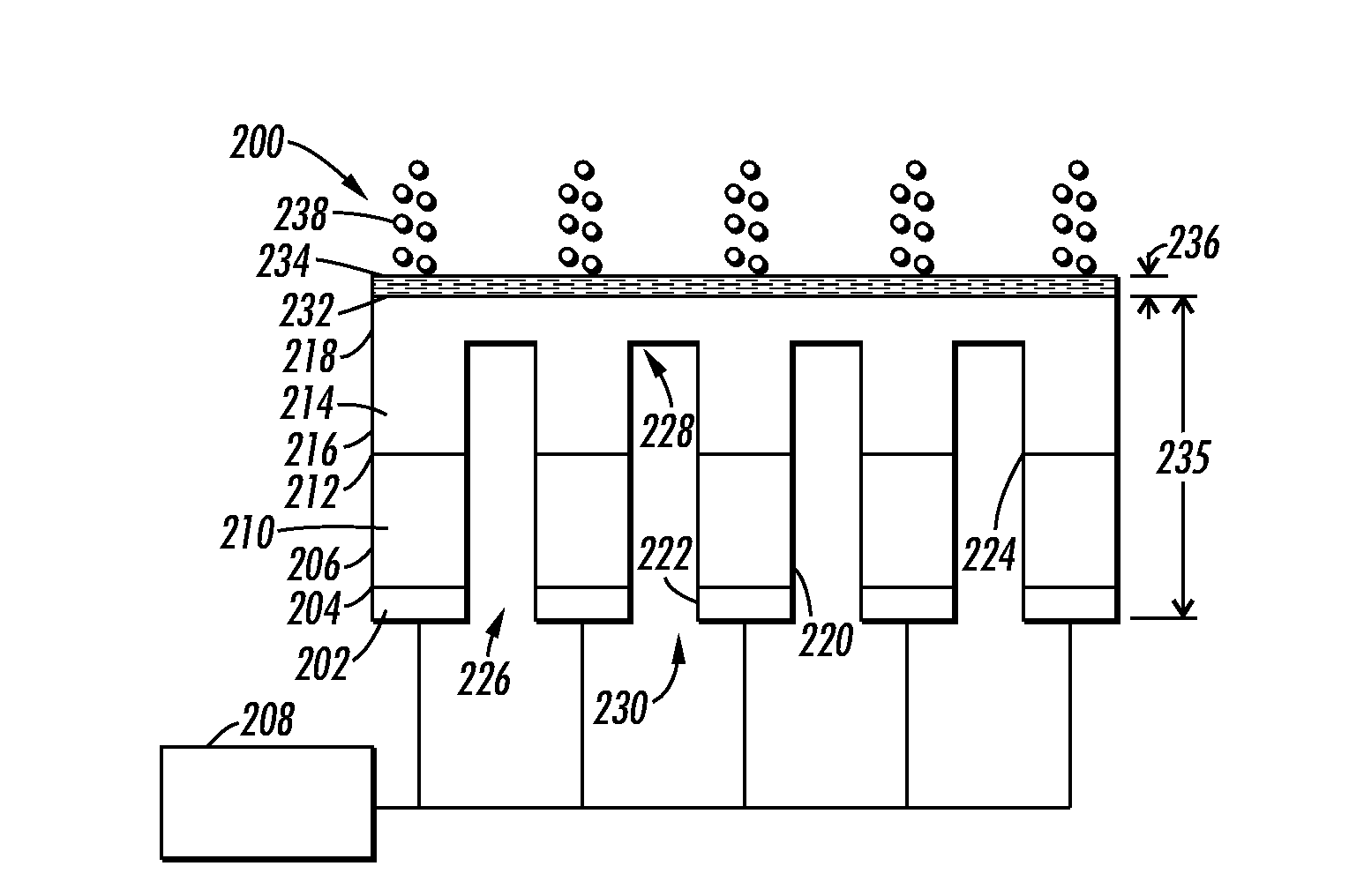

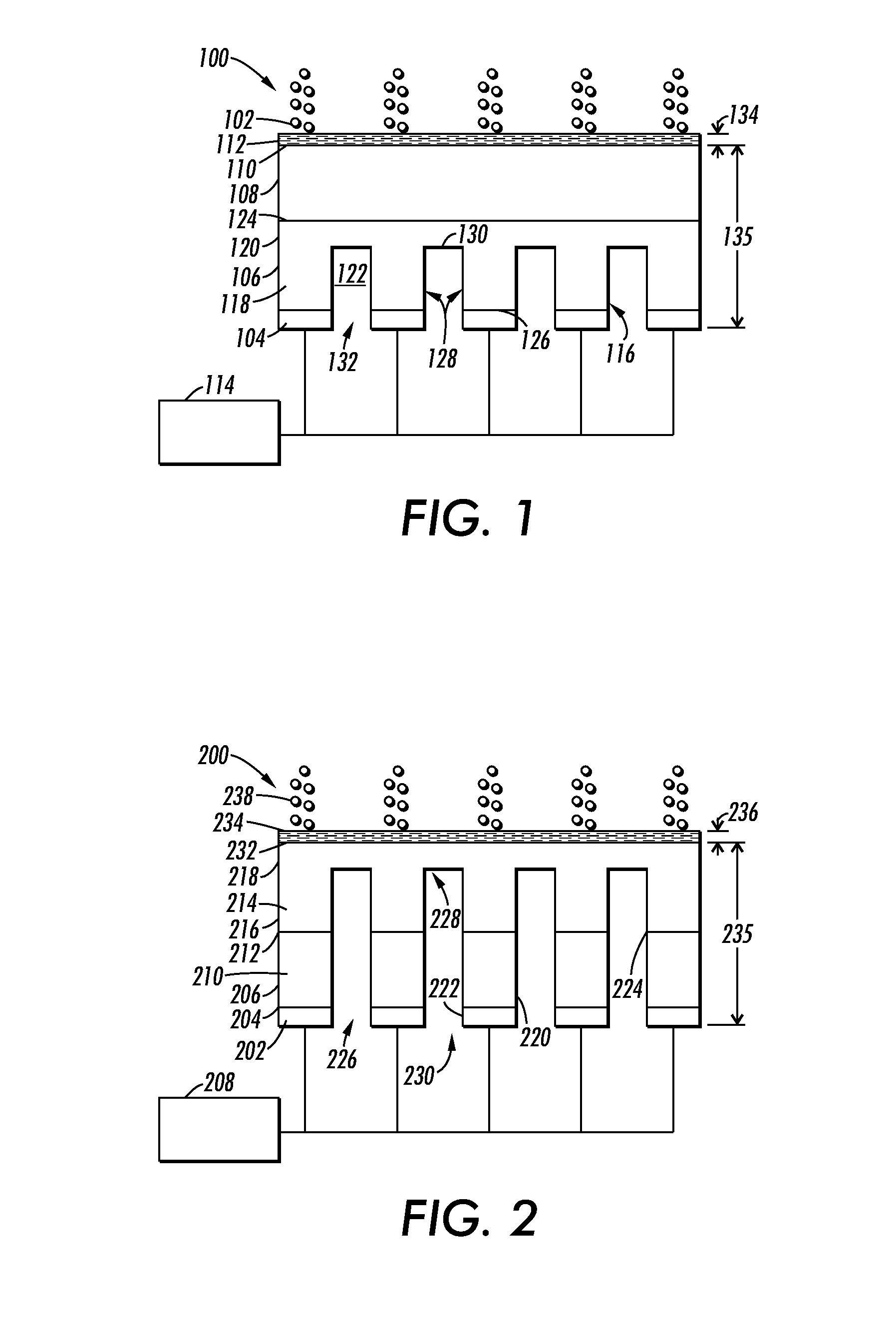

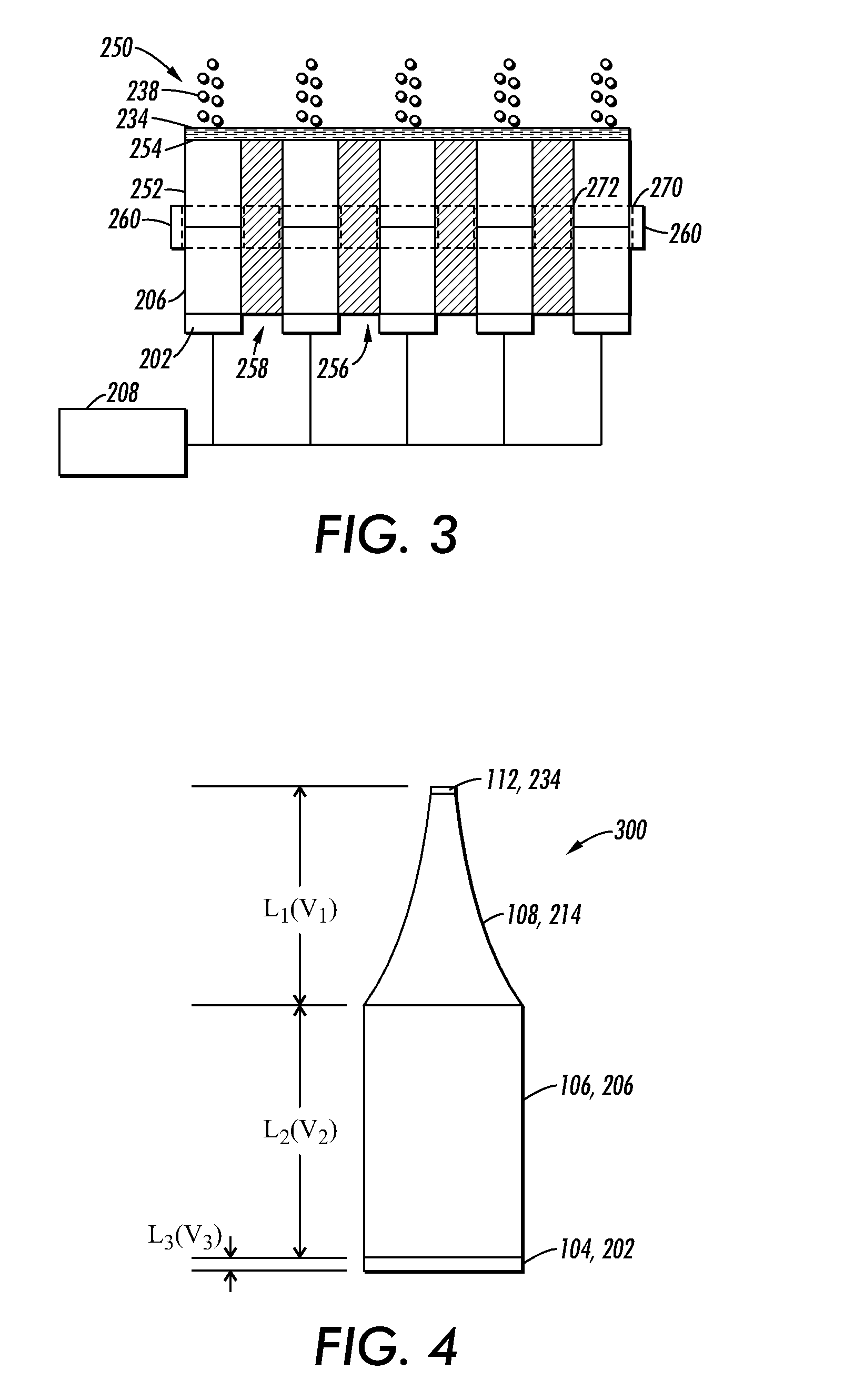

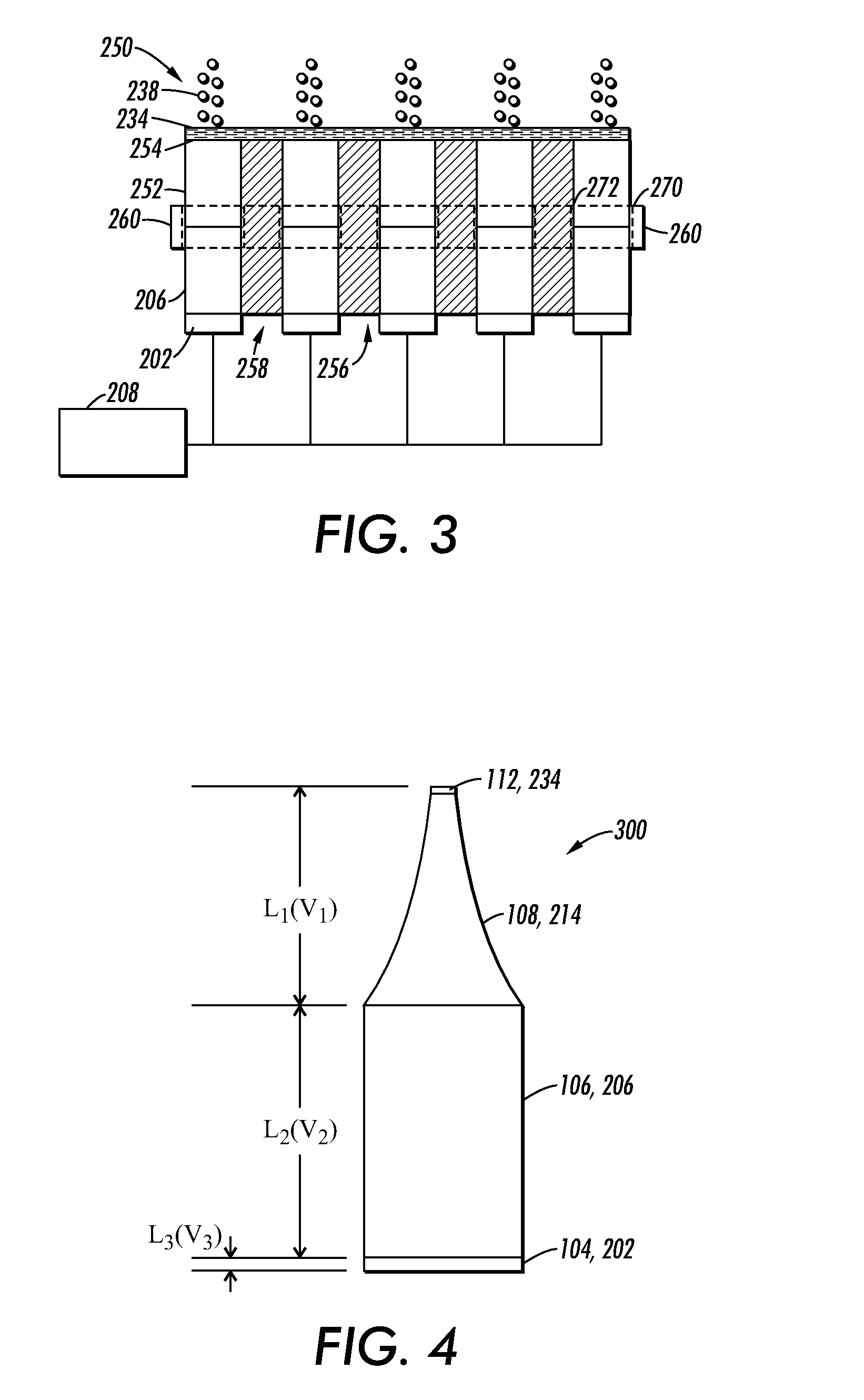

System and method for acoustic ejection of drops from a thin layer of fluid

Features described herein relate to ejecting drops from a thin layer of fluid. Piezoelectric elements can generate a uniform high acoustic field, which is transferred through a segmented metal support structure and an acoustic horn. The sound waves generate capillary waves on a thin layer of fluid on a top surface of the acoustic horn. At sufficiently high amplitudes, the capillary waves begin to break apart, resulting in the ejection of drops from the thin layer of fluid.

Owner:PALO ALTO RES CENT INC

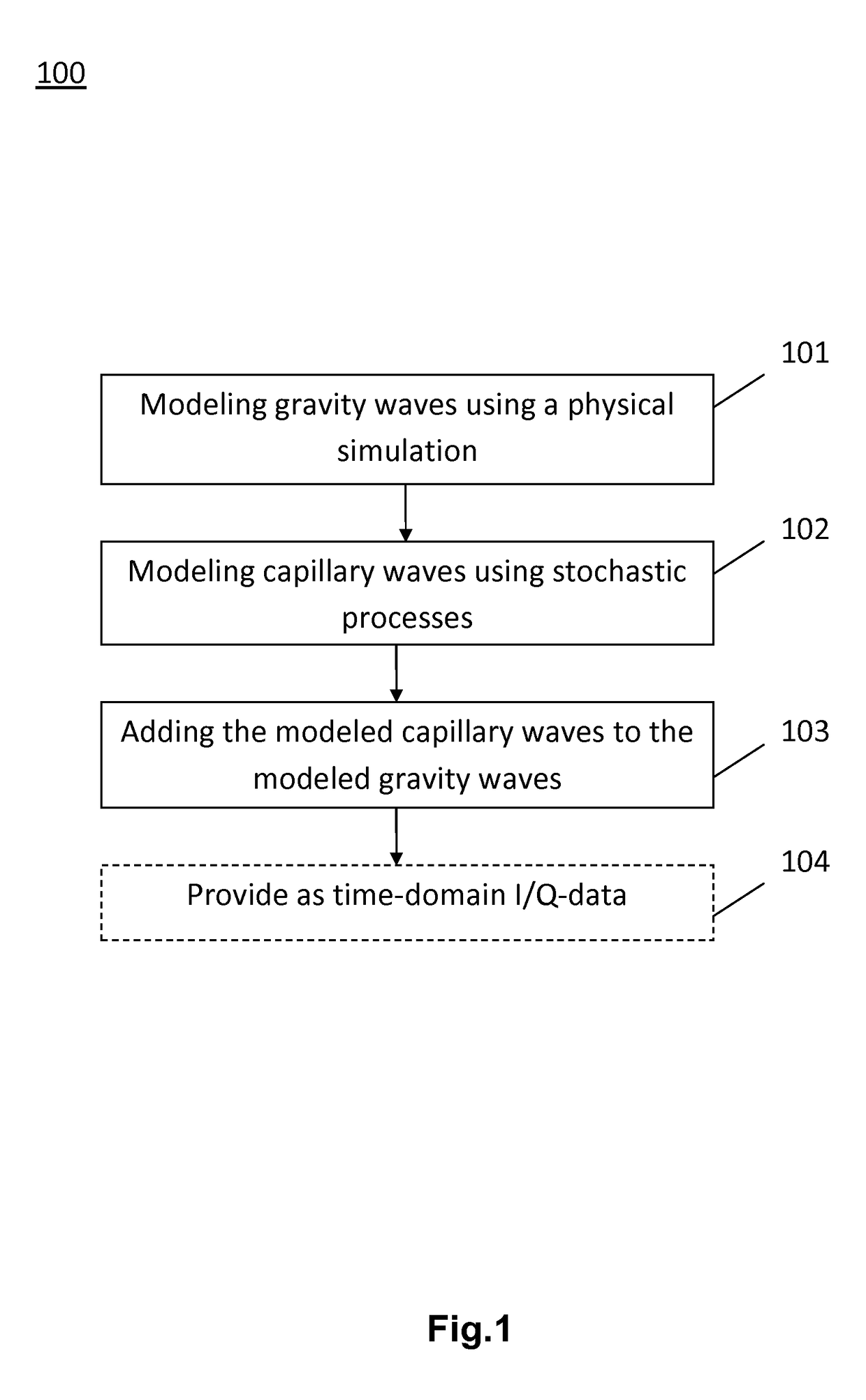

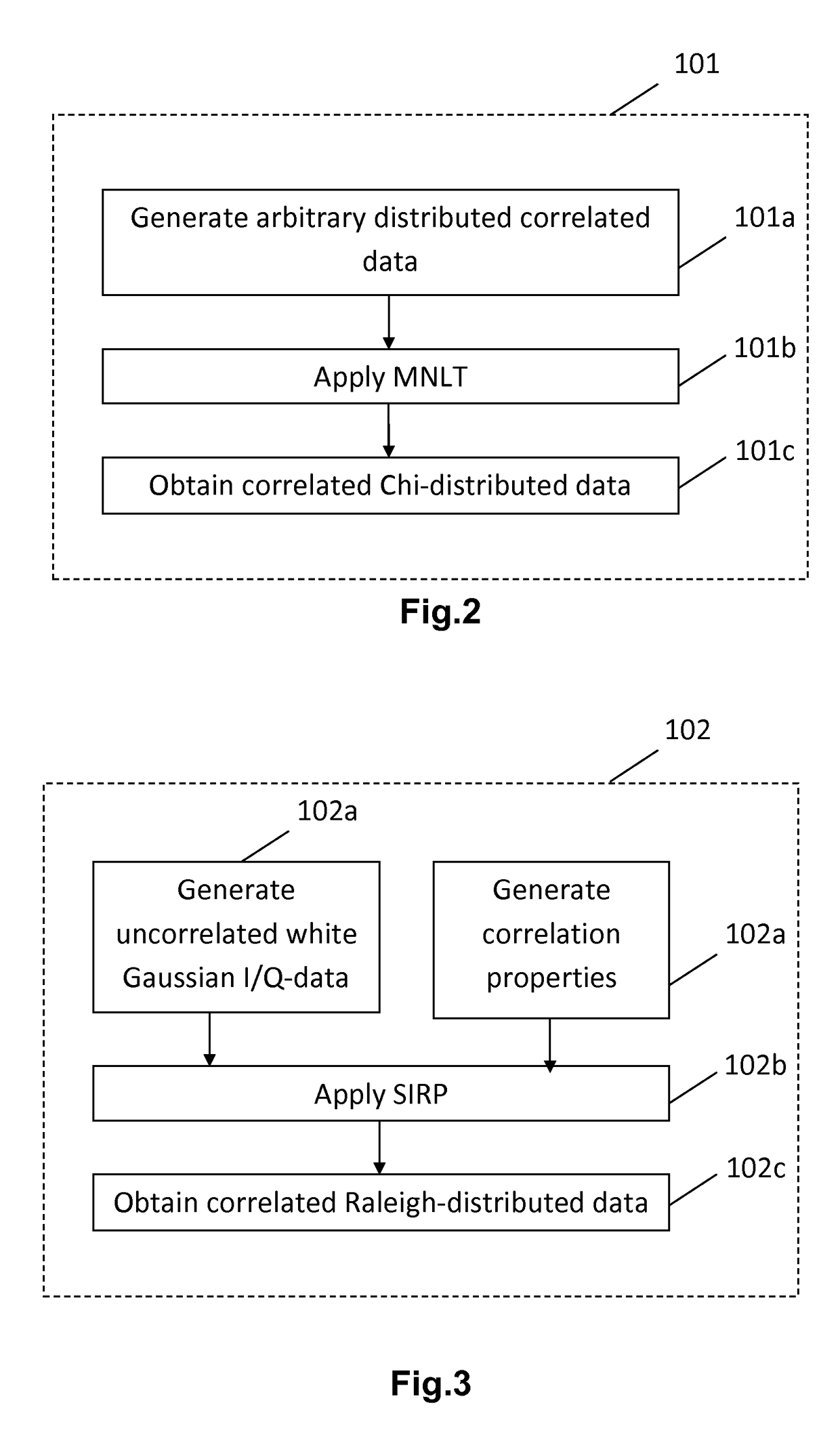

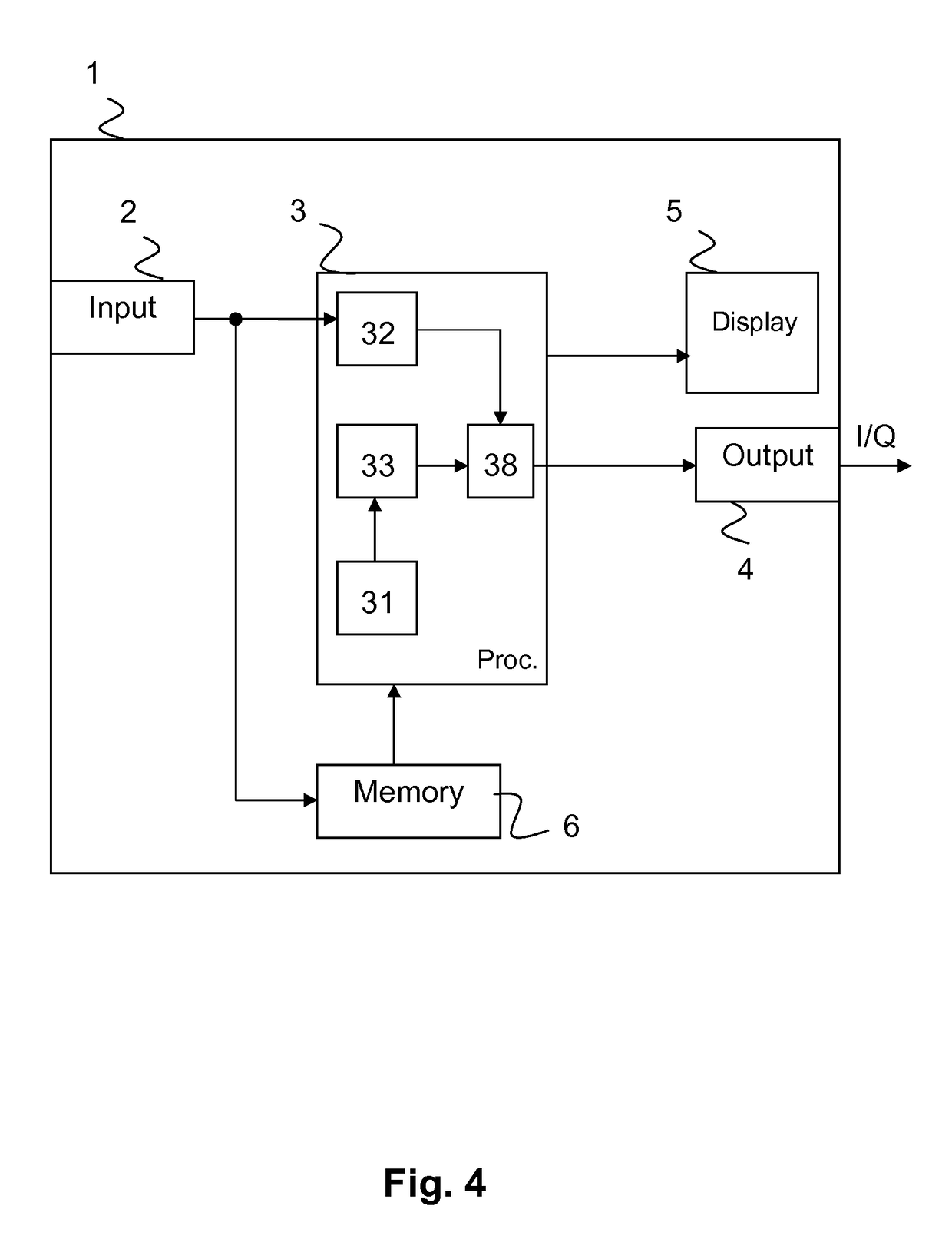

Method and signal generator for simulation of sea clutter

The invention is related to a method and a signal generator for generating a sea clutter simulation signal used as an input signal for a radar system. The method comprises the steps of: modeling of gravity waves using a physical simulation of a sea surface; modeling of capillary waves using stochastic processes; and adding the modeled capillary waves to the modeled gravity waves.

Owner:ROHDE & SCHWARZ GMBH & CO KG

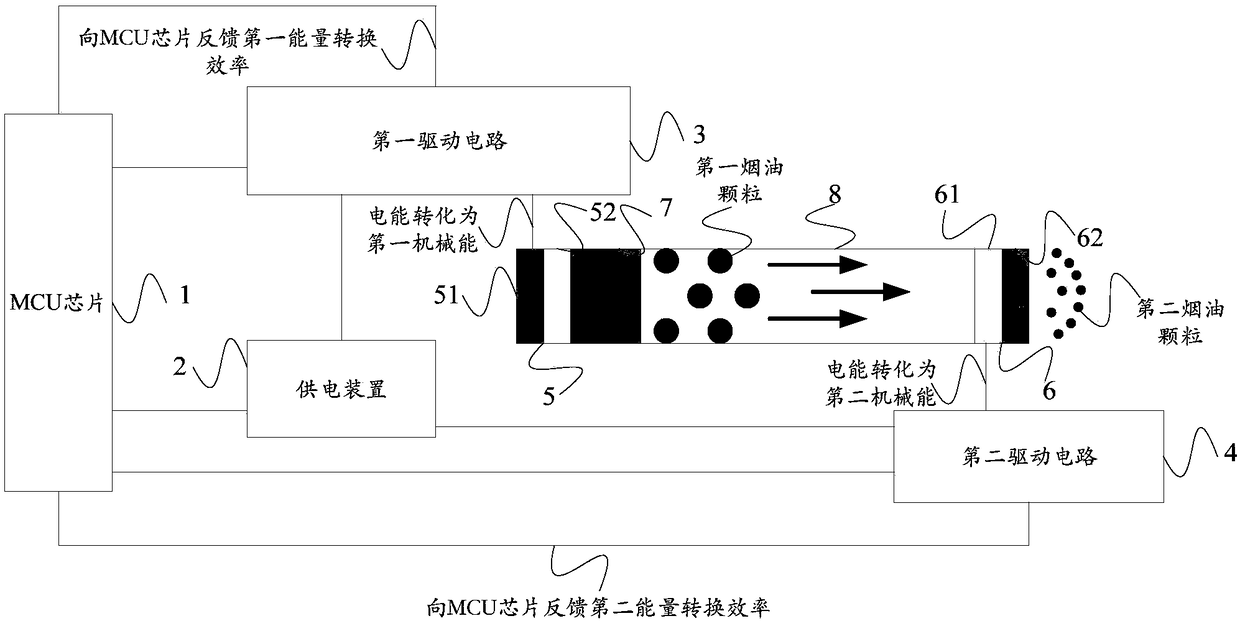

Tobacco tar ultrasonic atomization control circuit and tobacco tar ultrasonic atomization device

The application discloses a tobacco tar ultrasonic atomization control circuit and an electronic cigarette, wherein the tobacco tar ultrasonic atomization control circuit comprises a power supply device, an MCU (micro control unit) chip, a first drive circuit and a second drive circuit; the MCU chip is used for controlling and coordinating the first drive circuit and the second drive circuit whichare electrically connected with the MCU chip; the first drive circuit and the second drive circuit are respectively connected with the power supply device, and the first drive circuit is used for converting electric energy, which is output by the power supply device, into first mechanical energy for providing vibration wave; the vibration wave is used for crushing tobacco tar into first tobacco tar particles; the second drive circuit is used for converting the electric energy, which is output by the power supply device, into second mechanical energy for supplying surface tension wave, the surface tension wave is used for crushing the first tobacco tar particles into second tobacco tar particles, and the volumes of the second tobacco tar particles are less than those of the first tobacco tar particles. By adopting the tobacco tar ultrasonic atomization control circuit, the tobacco tar can be atomized, and the quantity of smoke is great.

Owner:SHENZHEN HANGSEN STAR TECH

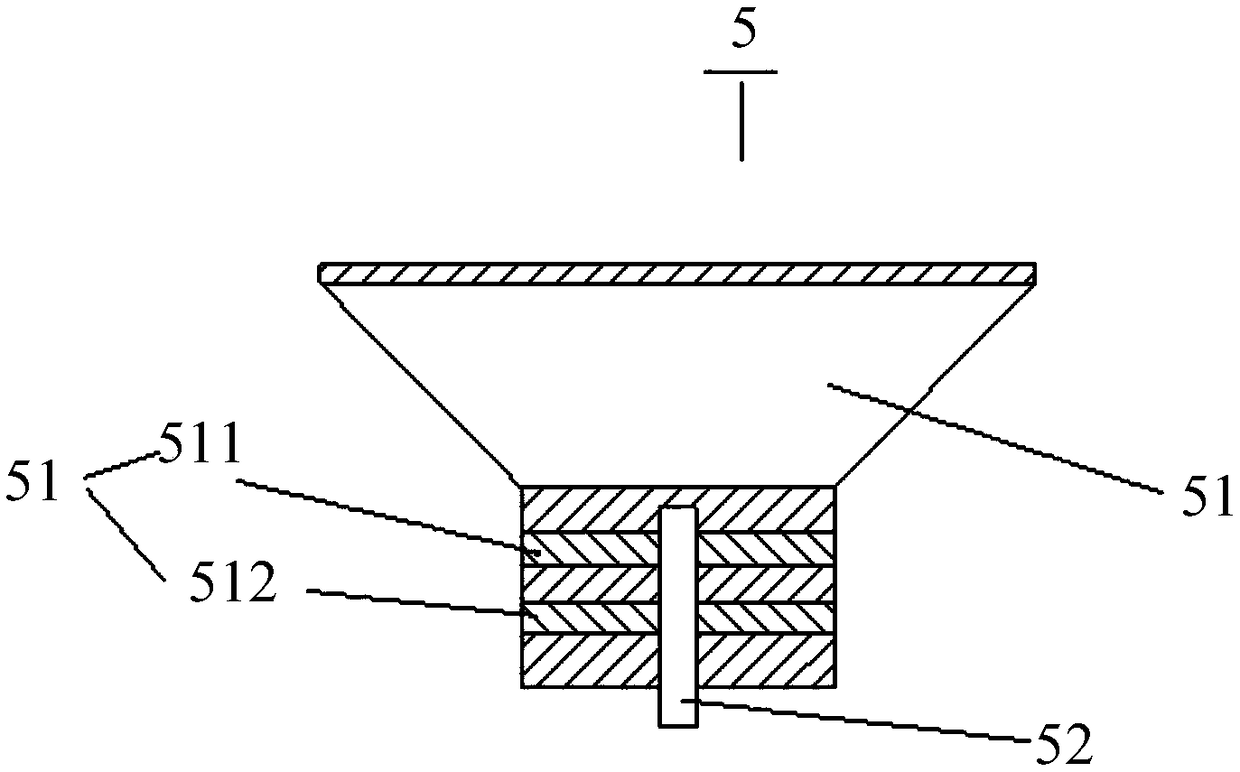

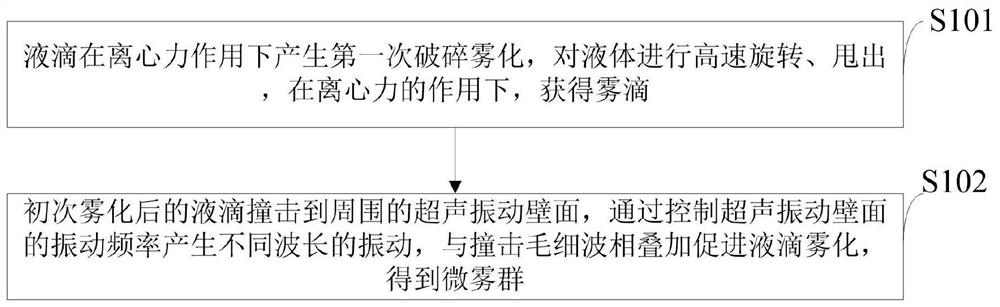

Centrifugal jet atomization and ultrasonic atomization combined method with water-saving characteristic

InactiveCN111841205AImprove atomization efficiencyTo achieve the purpose of saving waterUsing liquid separation agentDust controlControl ultrasound

The invention belongs to the technical field of dust control, and discloses a centrifugal jet atomization and ultrasonic atomization combined method with a water-saving characteristic, which comprisesthe following steps of: carrying out high-speed rotation and throwing on liquid, and primarily atomizing liquid drops under the action of centrifugal force to obtain fog drops of which the central particle size is less than 20 microns; and enabling the primarily atomized liquid drops to impact the surrounding ultrasonic vibration wall surface, generating vibration with different wavelengths by controlling the vibration frequency of the ultrasonic vibration wall surface, and superposing the vibration with impact capillary waves to promote the atomization of the liquid drops, so as to obtain amicro fog group with the particle size of less than 10 microns. A fog group with the central particle size smaller than 20 microns is obtained through a crushing atomization mechanism under the actionof centrifugal force and transverse air flow, and then a micro fog group with the central particle size smaller than 10 microns is obtained through further crushing by utilizing the atomization mechanism of impacting the ultrasonic vibration wall surface. The atomization efficiency is improved by controlling the incident speed of liquid drops, the wettability and roughness of the solid surface, the viscosity of the liquid drops, the radius of the liquid drops and other parameters, and the purpose of water saving is achieved.

Owner:CHONGQING VOCATIONAL INST OF ENG

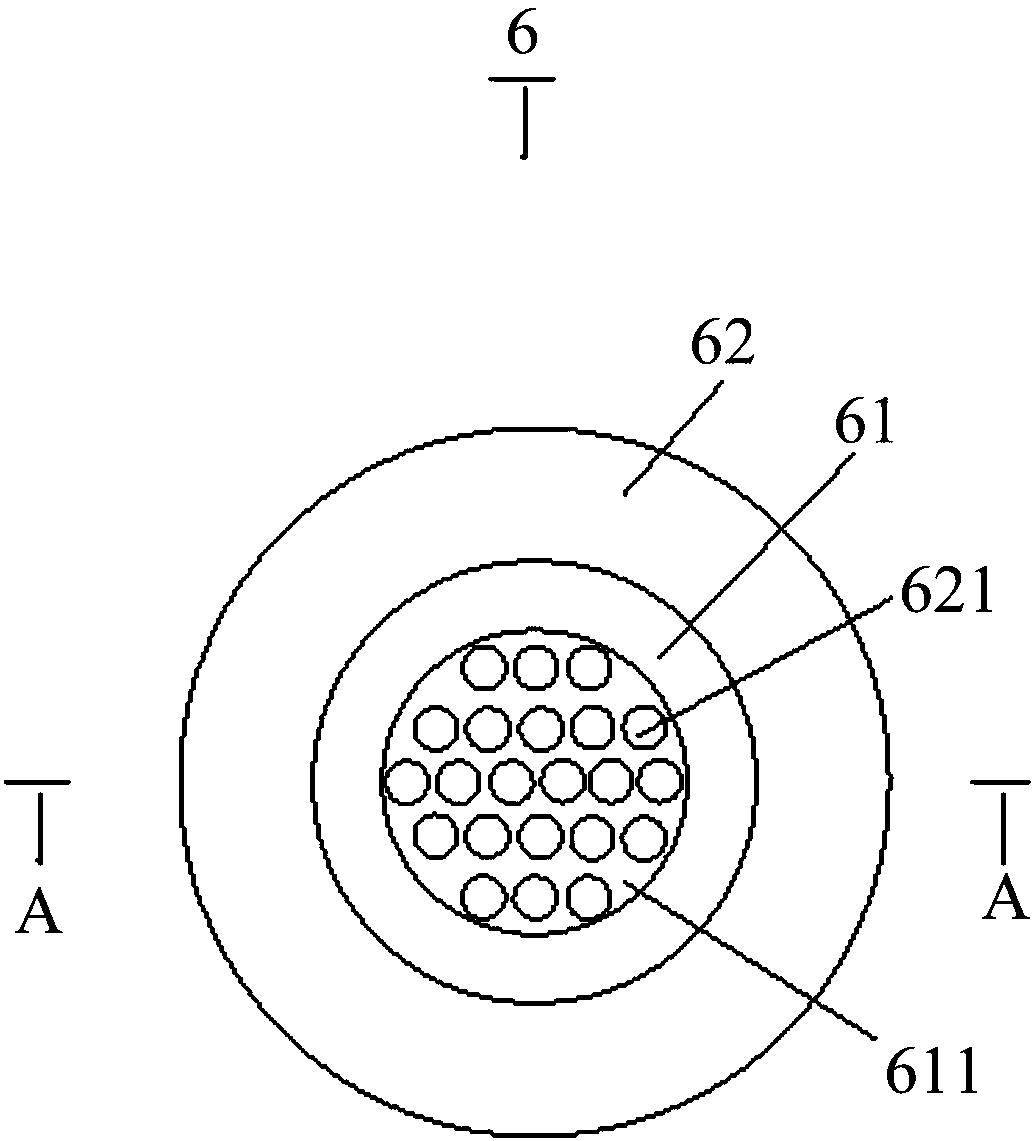

Crushing atomization method by liquid droplets impacting ultrasonic vibration wall and application

InactiveCN111841992APromote atomizationSmall particle sizeUsing liquid separation agentLiquid spraying apparatusVibration amplitudeDust control

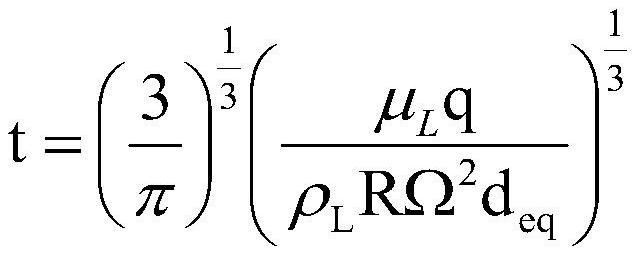

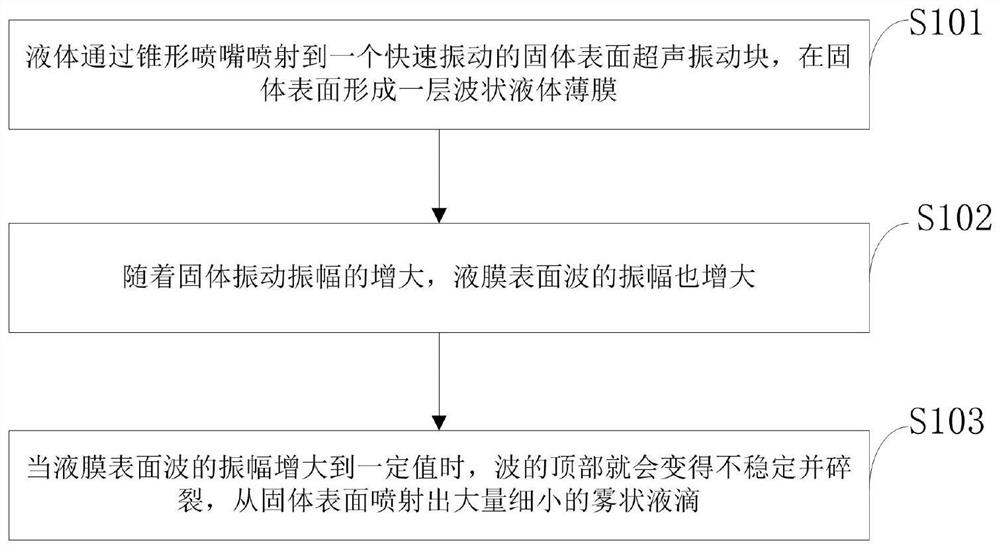

The invention belongs to the technical field of dust removal, and discloses a crushing atomization method by liquid droplets impacting an ultrasonic vibration wall and application. Liquid is sprayed through a conical nozzle to a rapidly vibrating ultrasonic vibration block with a solid surface, and forms a layer of wavy liquid film on the solid surface; with the increase of the vibration amplitudeof solid, the vibration amplitude of surface waves of the liquid film is also increased; and when the vibration amplitude of surface waves of the liquid film is increased to a certain value, the topsof the waves can become unstable and break apart, and a lot of tiny liquid droplets of mist can be sprayed out from the solid surface. According to the ultrasonic atomization theory, the invention provides the atomization method by liquid droplets impacting the ultrasonic vibration wall. The atomization method produces vibration of different wavelengths by controlling the vibration frequency andimpacts capillary waves to promote the atomization of liquid droplets, so as to obtain a mist group with the medium particle diameter of the liquid droplets being less than 10 Mu m. The crushing atomization method adopts the mode of two times of atomization, the first atomization is produced when pressurized liquid is sprayed out by the nozzle, and the second atomization is produced when the liquid droplets impact the ultrasonic vibration wall.

Owner:CHONGQING VOCATIONAL INST OF ENG

Ultrasonic cleaning apparatus

ActiveUS9901962B2Damage can be be suppressedPrevent re-adhesionSemiconductor/solid-state device manufacturingElectrostatic cleaningUltrasonic sensorMegasonic cleaning

There are provided an ultrasonic cleaning apparatus and an ultrasonic cleaning method capable of suppressing occurrence of damage on a substrate to be cleaned and capable of performing cleaning at a high cleaning level for highly precise substrates and the like used in an electronics industry. Occurrence of damage on the substrate to be cleaned is suppressed by holding an object to be cleaned so as to be positioned out of a region where perpendiculars extend from an oscillating surface of an ultrasonic transducer to a liquid surface (an ultrasonic-irradiated region) under and in the vicinity of the liquid surface of a cleaning solution, exciting a capillary wave on a surface of the cleaning solution by an ultrasonic wave, and separating particulate contamination of the object to be cleaned by an acoustic pressure generated by the capillary wave without irradiating the object to be cleaned directly with the ultrasonic wave.

Owner:KAIJOO KK

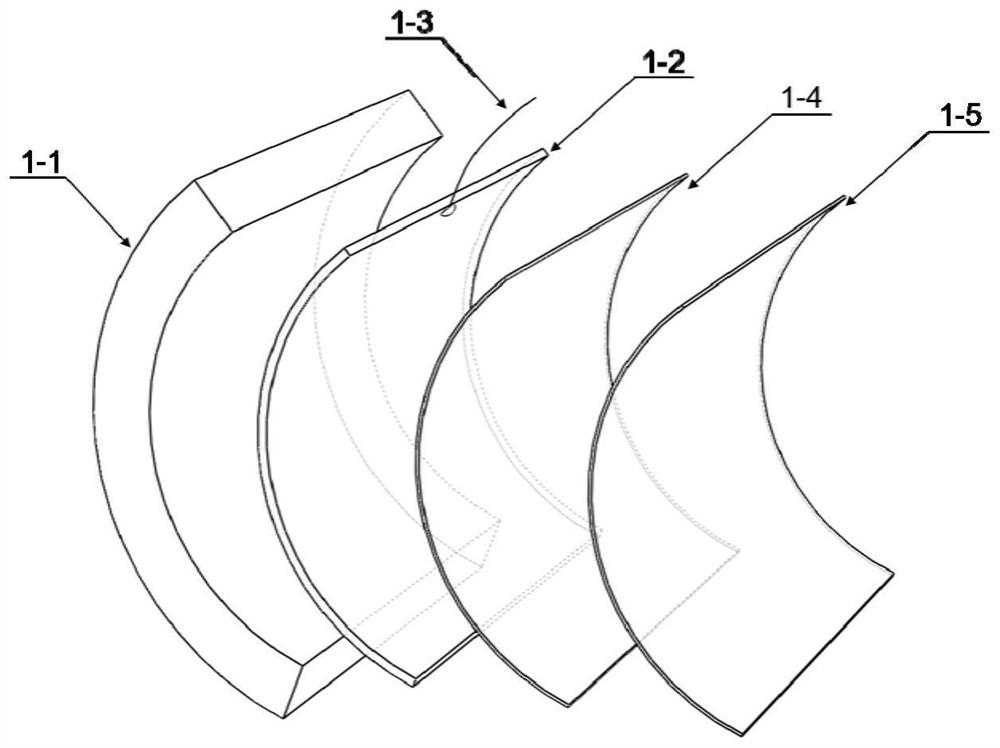

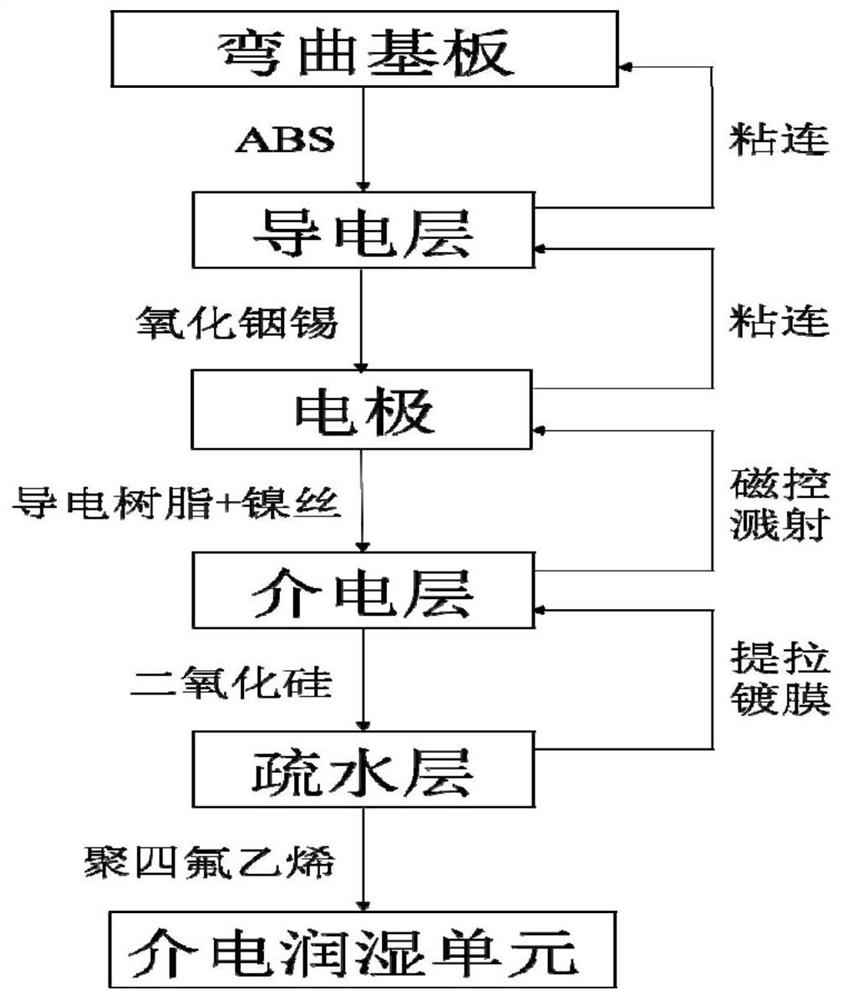

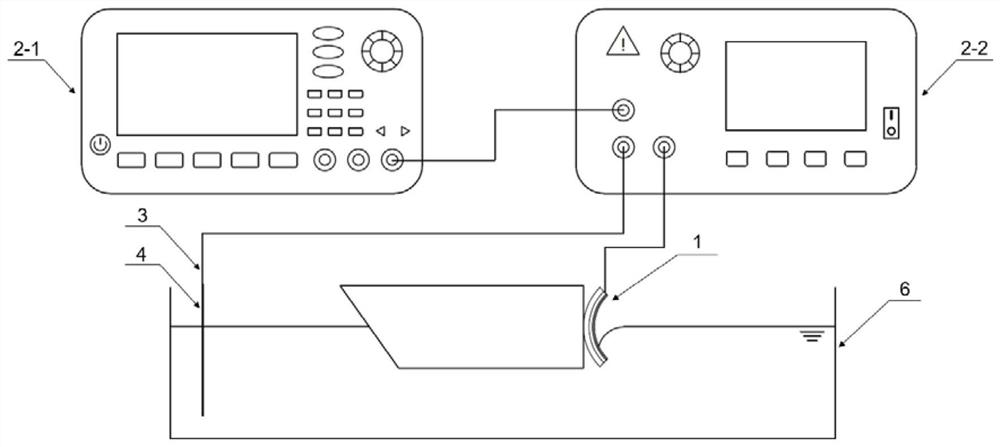

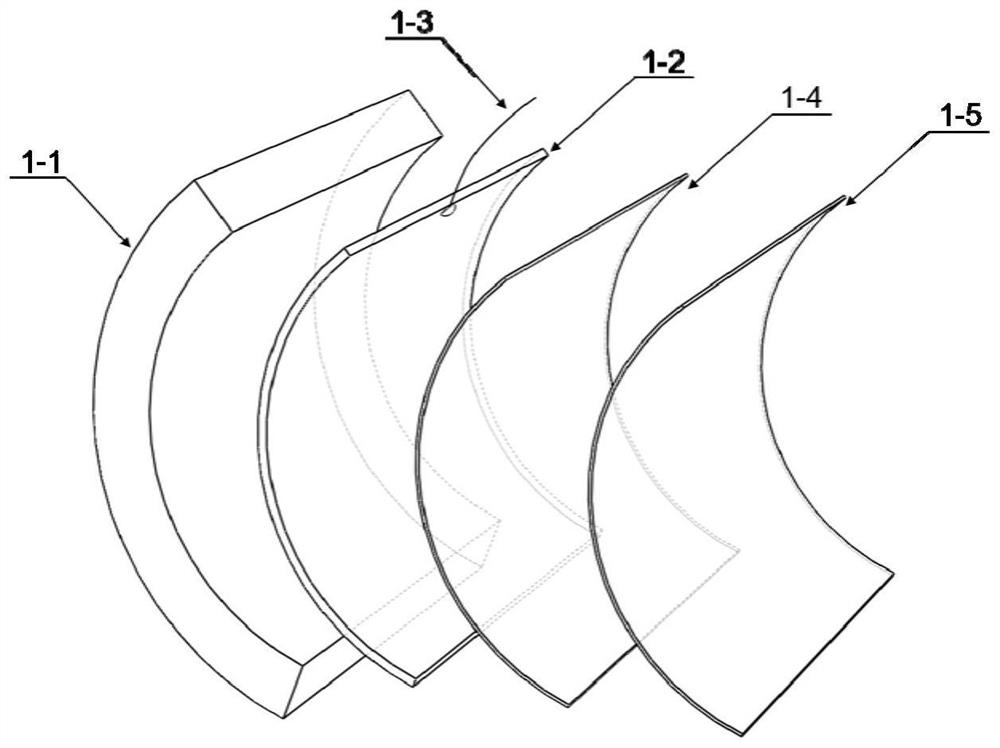

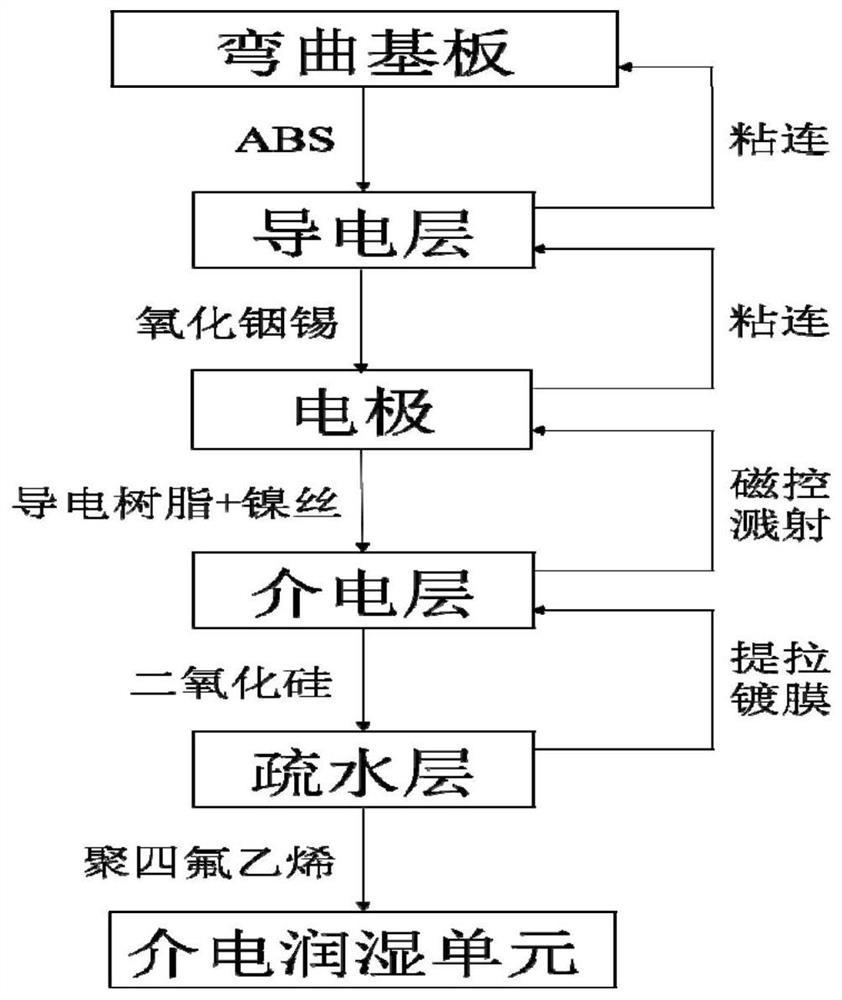

Bent capillary wave propeller, production method and propelling system

ActiveCN113753210ALarge contact angle changeReduce distancePropulsion based emission reductionPropulsive elements of non-rotary typeRepulsion forceEngineering

The invention discloses a bent capillary wave propeller, a production method of the bent capillary wave propeller and a propelling system based on the bent capillary wave propeller. The bent capillary wave propeller structurally comprises a bent substrate, a conductive layer, an electrode, a dielectric layer and a hydrophobic layer. The conductive layer is adhered to the substrate, the electrode is adhered to the conductive layer, the dielectric layer is sprayed on the conductive layer and the dielectric layer in a magnetron sputtering manner, and the hydrophobic layer is adhered to the dielectric layer. In the working state, the initial contact angle between the bent capillary wave propeller and a liquid is 129 degrees, and after an electric signal is applied, the contact angle changes to 68 degrees. By changing the shape of a substrate of the capillary wave propeller, when the curvature of the capillary wave propeller is larger, capillary waves close to the hydrophobic layer are bound in a smaller space, the distance between charges of the same kind carried by the liquid is reduced, a coulomb force between the charges is increased, a repulsive force is increased, the change of a contact angle is larger, and therefore the amplitude of the capillary waves is increased.

Owner:DALIAN UNIV OF TECH

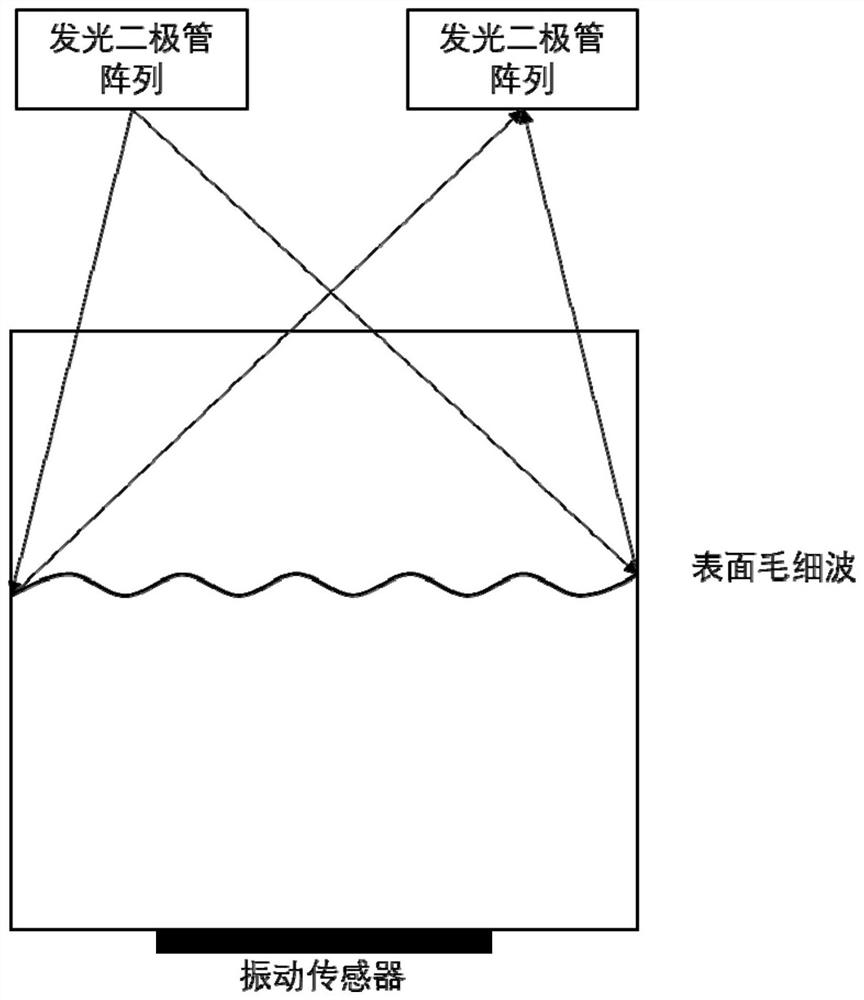

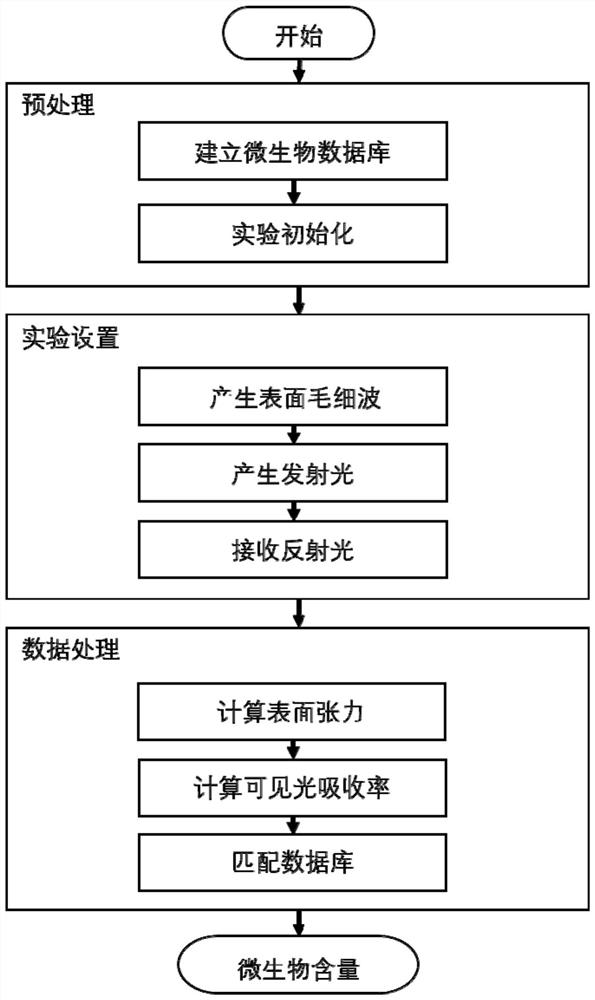

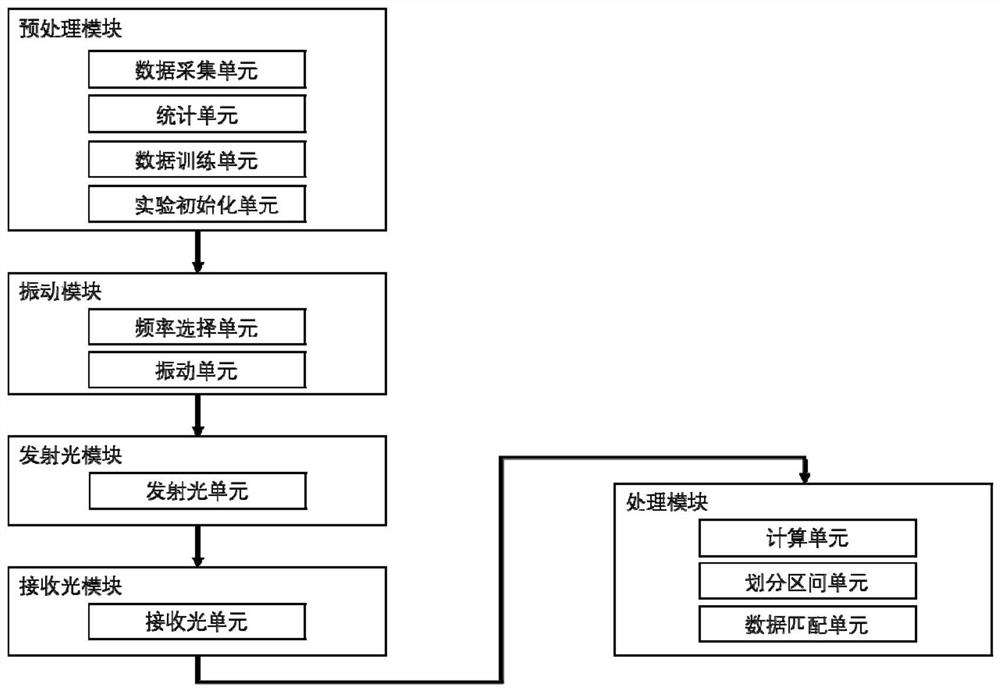

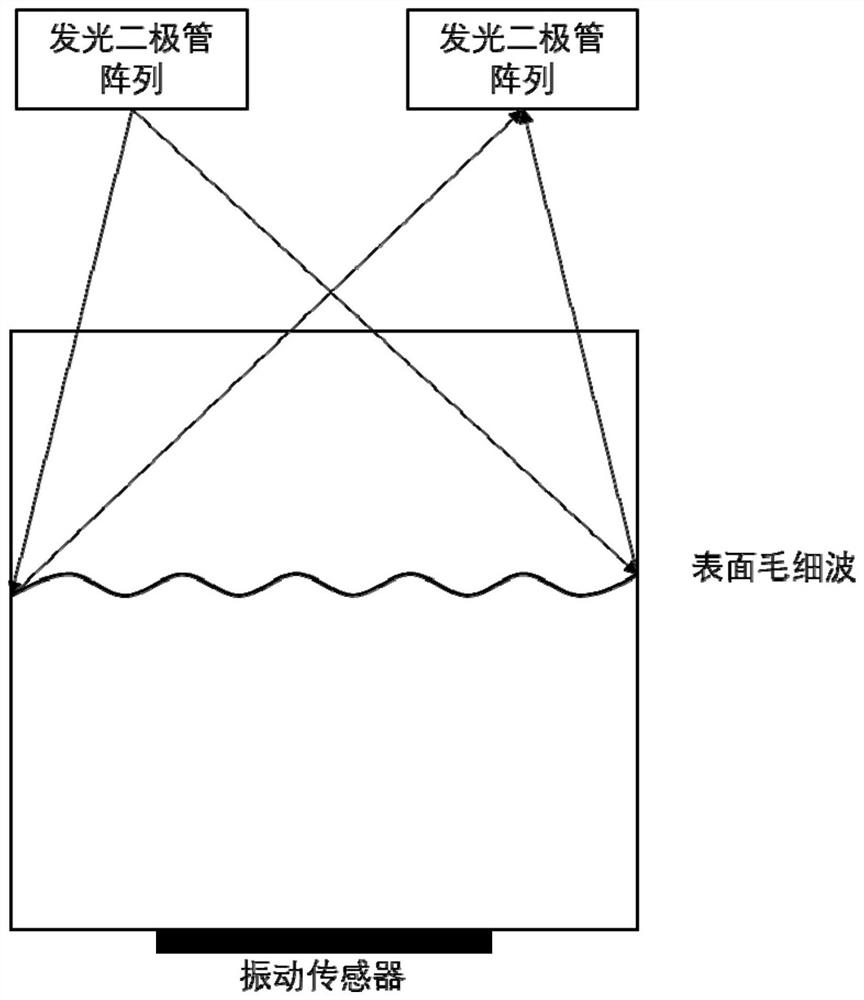

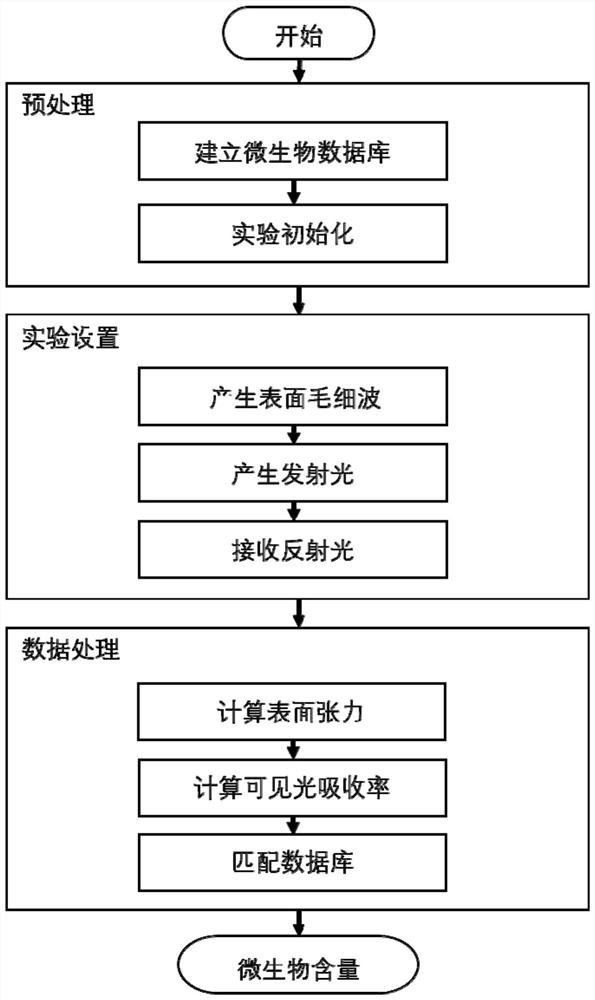

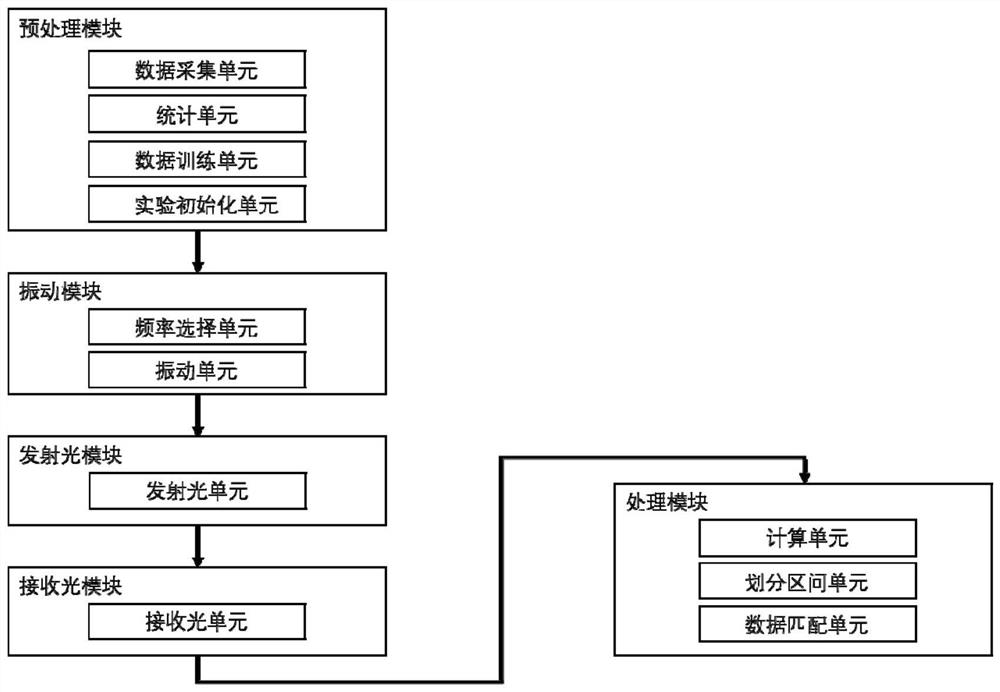

A liquid deterioration monitoring method and system based on visible light

ActiveCN112858112BHigh precisionHigh sensitivityColor/spectral properties measurementsSurface tension analysisMicroorganismLiquid surfaces

The invention discloses a liquid deterioration monitoring method and system based on visible light. The method includes: vibrating the liquid to be measured by a vibration sensor, so that the surface of the liquid generates surface capillary waves under the action of surface tension; using a combination of light sources to emit a variety of visible lights of different colors, and irradiating the liquid surface; receiving light reflected by the capillary waves on the liquid surface Visible light: For the intensity change data of the received visible light, analyze the frequency deviation relationship of the reflected light to obtain the wavelength of the capillary wave on the liquid surface, and then use the wavelength of the surface capillary wave to calculate the surface tension of the liquid; for the received visible light, analyze the different The light intensity absorbed by the liquid under the visible light of the color can be used to obtain the color of the liquid, and then the type of liquid and the microbial content in the liquid can be obtained by combining the color and surface tension. The invention can realize higher precision and low cost liquid deterioration monitoring.

Owner:SHENZHEN UNIV

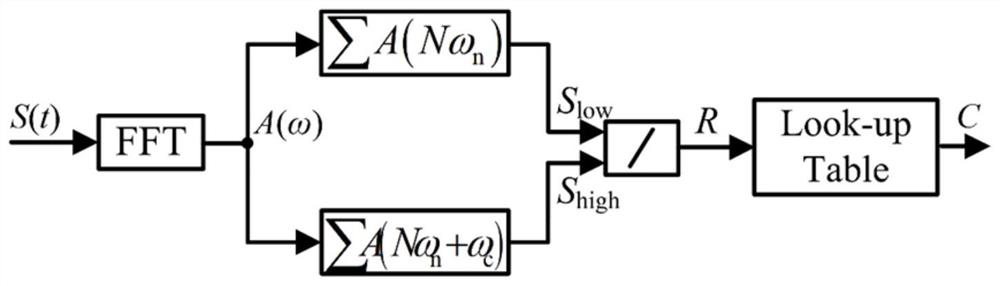

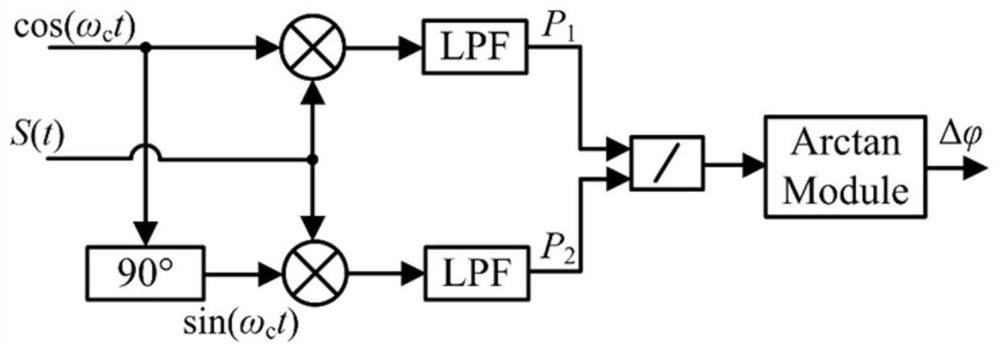

A sine phase modulation laser interferometer and carrier generation and signal demodulation method

ActiveCN113175867BImplement carrier generationGood interferenceUsing optical meansCarrier signalTransducer

The invention discloses a sine phase modulation laser interferometer and a carrier wave generation and signal demodulation method. The high-frequency acoustic waves are used to generate high-frequency liquid surface acoustic waves at the gas-liquid interface, and the reference light of the homodyne interferometer is incident on the gas-liquid interface. At the interface, the high-frequency liquid surface acoustic wave modulates the phase of the reference light to realize the generation of the phase carrier of the homodyne interference signal; it can solve the problem that the existing PGC demodulation method needs to realize the high-frequency sinusoidal phase modulation of the reference arm of the homodyne interferometer, and realize the High frequency sinusoidal phase modulation requires expensive components. The invention adopts Arctan demodulation algorithm based on real-time normalization to eliminate the influence of carrier phase delay caused by low-frequency capillary waves on liquid surface and carrier modulation depth variation caused by power fluctuation of electroacoustic transducer on demodulation results.

Owner:ZHEJIANG SCI-TECH UNIV

System and method for acoustic ejection of drops from a thin layer of fluid

Owner:PALO ALTO RES CENT INC

Method and device for polymerizing a composition comprising hydridosilanes and subsequently using the polymers to produce silicon-containing layers

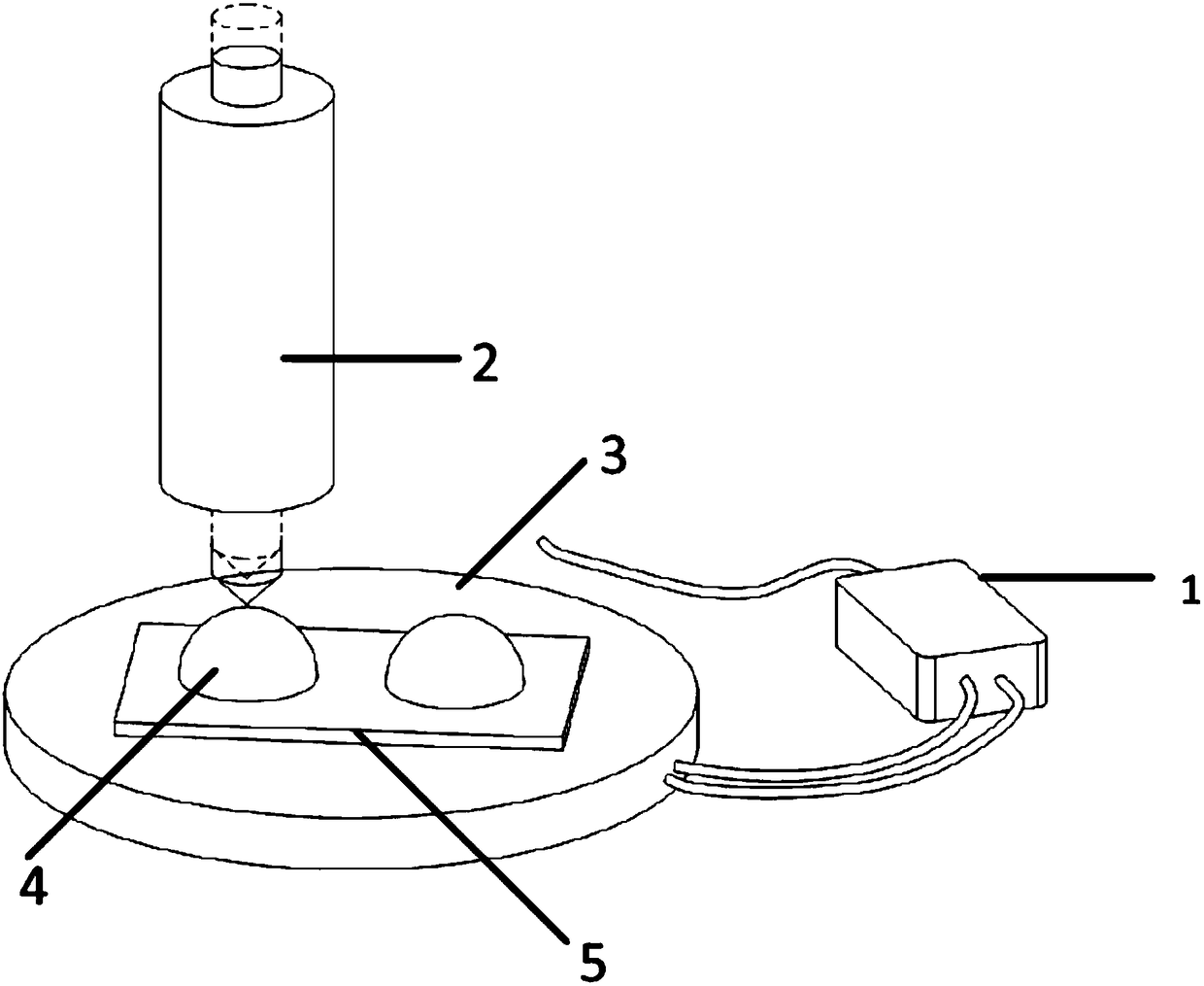

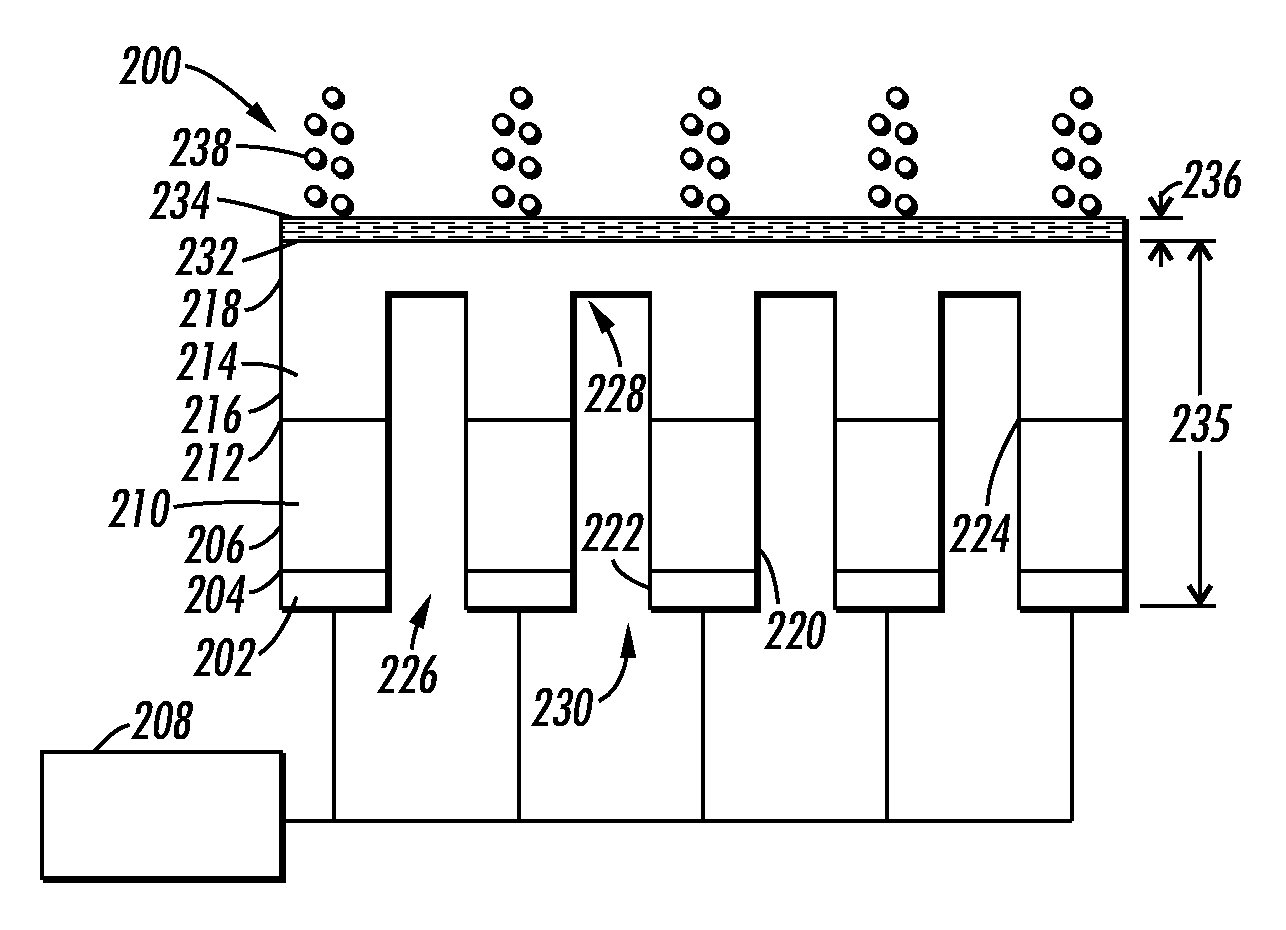

ActiveUS10053599B2Heat dissipationReduce liquid volumeSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingCavitationNoble gas

A method for polymerizing a composition including hydridosilanes and subsequently using the polymers to produce silicon containing layers, comprising the following steps: a) providing a substrate; b) providing a composition including at least one hydridosilane that is dissolved in at least one organic and / or inorganic solvent, or including at least one hydridosilane that is already present in liquid form without solvent, wherein the hydridosilanes comprise at least one linear and / or one branched hydridosilane of the general formula SinH2n+2, where n≥3, and / or a cyclic hydridosilane of the general formula SinH2n, where n≥3; c) polymerizing the composition from step b) by way of acoustic cavitation; and d) coating the surface of the substrate with reaction products from step c). A device for polymerizing a composition including hydridosilanes and subsequently using the polymers to produce silicon containing layers, comprising at least one reaction vessel (1) containing a composition that includes at least one hydridosilane that is dissolved in at least one organic and / or inorganic solvent, or at least one hydridosilane that is already present in liquid form without solvent, wherein the hydridosilanes comprise at least one linear and / or branched hydridosilane of the general formula SinH2n+2, where n≥3, and / or a cyclic hydridosilane of the general formula SinH2n, where n≥3, and / or containing the abovementioned hydridosilane solution or the pure liquid hydridosilane, to which at least monosilane and / or disilane and / or boron containing dopant and / or phosphorus containing dopant and / or a noble gas from the group Ar, He and / or nanoparticles and / or a polymerization initiator and / or a catalyst and / or surface tension modifying agents can be added, and an ultrasound source and / or a sound transducer (4) for generating acoustic cavitation and / or capillary waves, wherein the reaction vessel (1) has at least one closable opening (6), the substrate (8) to be coated is disposed opposite the opening (6), and the substrate (8) comprises a heating source (9) on the surface that faces away from the coating surface.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

Liquid deterioration monitoring method and system based on visible light

ActiveCN112858112AHigh precisionHigh sensitivityColor/spectral properties measurementsSurface tension analysisMicroorganismSurface tension force

The invention discloses a liquid deterioration monitoring method and system based on visible light. The method comprises the following steps: vibrating to-be-detected liquid through a vibration sensor, so that surface capillary waves are generated on the surface of the liquid under the action of surface tension; using a light source combination to emit visible light with various different colors to irradiate the surface of liquid; receiving visible light reflected by capillary waves on the surface of the liquid; for the received light intensity change data of the visible light, analyzing the frequency offset relationship of the reflected light to obtain the wavelength of the capillary wave on the surface of the liquid, and further calculating the surface tension of the liquid by utilizing the wavelength of the capillary wave on the surface; for the received visible light, obtaining the color of the liquid by analyzing the light intensity absorbed by the liquid under the visible light with different colors, and then obtaining the type of the liquid and the content condition of microorganisms in the liquid by integrating the color and the surface tension. According to the invention, liquid deterioration monitoring with higher precision and low cost can be realized.

Owner:SHENZHEN UNIV

A curved capillary wave propeller and preparation method and propulsion system

ActiveCN113753210BLarge contact angle changeReduce distancePropulsion based emission reductionPropulsive elements of non-rotary typeSputteringRepulsion force

The invention discloses a curved capillary wave thruster, a preparation method of the curved capillary wave thruster, and a propulsion system based on the curved capillary wave thruster. The structure of the curved capillary wave thruster comprises: a curved substrate, a conductive layer, an electrode, Dielectric layer and hydrophobic layer; the conductive layer is adhered to the substrate, the electrode is adhered to the conductive layer, the dielectric layer is sprayed on the conductive layer and the dielectric layer by magnetron sputtering, and the hydrophobic layer is adhered to the dielectric layer. on the electrical layer. In the working state, the initial contact angle of the curved capillary wave propeller with the liquid is 129°. After applying the electrical signal, the contact angle changes to 68°. By changing the shape of the capillary wave thruster substrate, when the curvature of the capillary wave thruster is larger, the capillary waves close to the hydrophobic layer are bound in a smaller space, and the distance between the same charges carried by the liquid decreases, and they The Coulomb force between them increases and the repulsive force increases, which makes the contact angle change more and thus causes the capillary wave amplitude to increase.

Owner:DALIAN UNIV OF TECH

Ultrasonic spray-forming method

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com