System, method and application for detecting liquid density

A liquid density and liquid technology, applied in the field of liquid density detection system, can solve the problems of increasing the complexity of the detection process, ammonia pollution, time-consuming and labor-intensive problems, and achieve the effect of improving measurement efficiency, reducing labor costs, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0024] In order to overcome the problems of non-real-time continuous measurement and contaminated liquid caused by the contact method used in the prior art to measure liquid density, the present invention provides a non-contact method for measuring liquid density that combines Doppler vibrometers and grating diffraction principles. system.

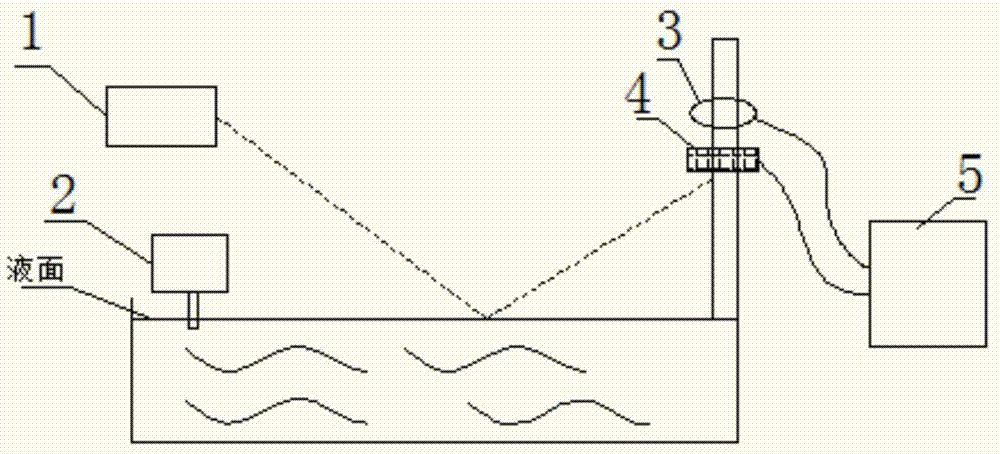

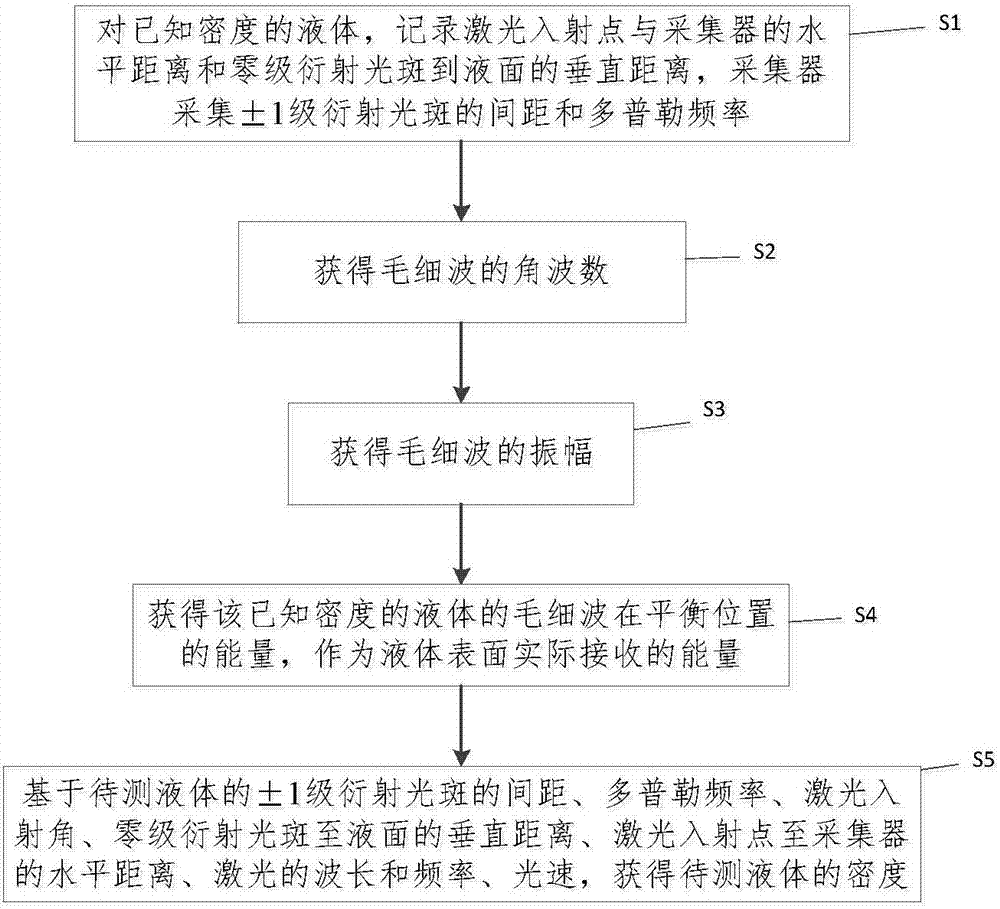

[0025] figure 1 A schematic structural diagram of a system for measuring liquid density according to an embodiment of the present invention is shown, by figure 1 It can be seen that this system includes:

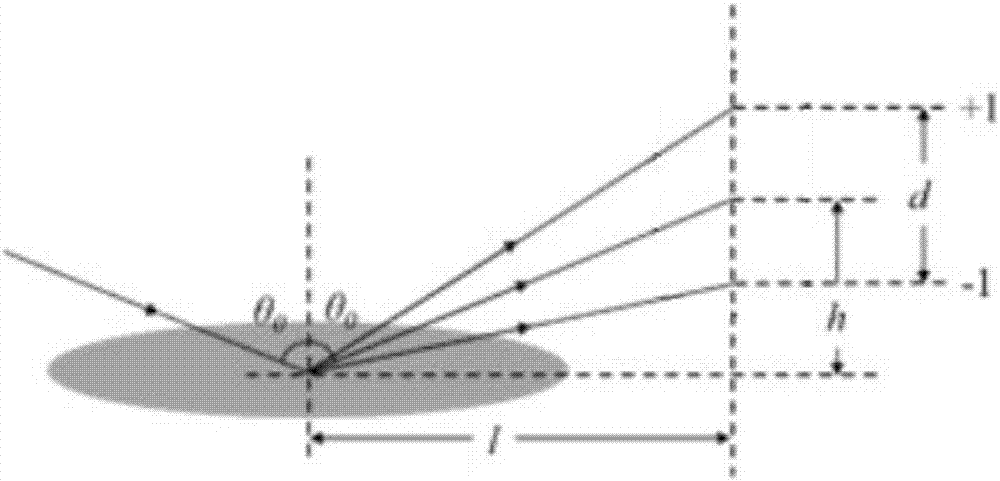

[0026] The laser generator 1 is used to emit laser light of a certain wavelength to the surface of the liquid at a certain angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com