Tobacco tar ultrasonic atomization control circuit and tobacco tar ultrasonic atomization device

An ultrasonic atomization and control circuit technology, which is applied in the field of electronic cigarettes, can solve the problems of complex atomization structure devices, difficulty in conforming to product resonance, and high smoke oil density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The technical solutions in this application will be clearly and completely described below in conjunction with the accompanying drawings in this application.

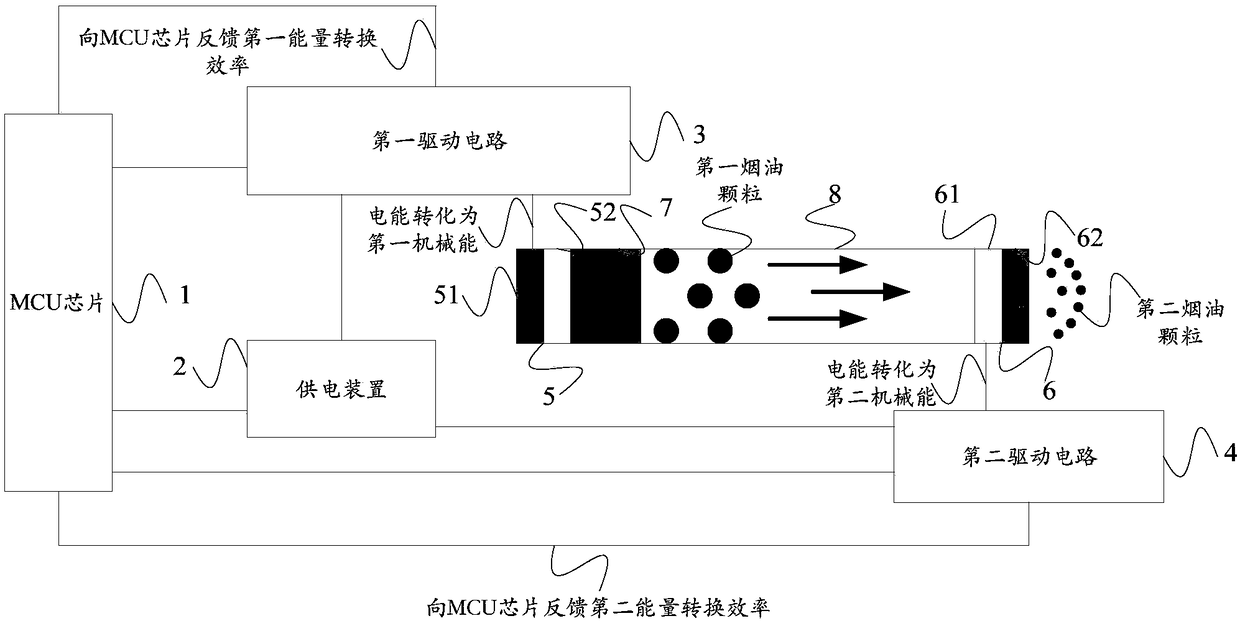

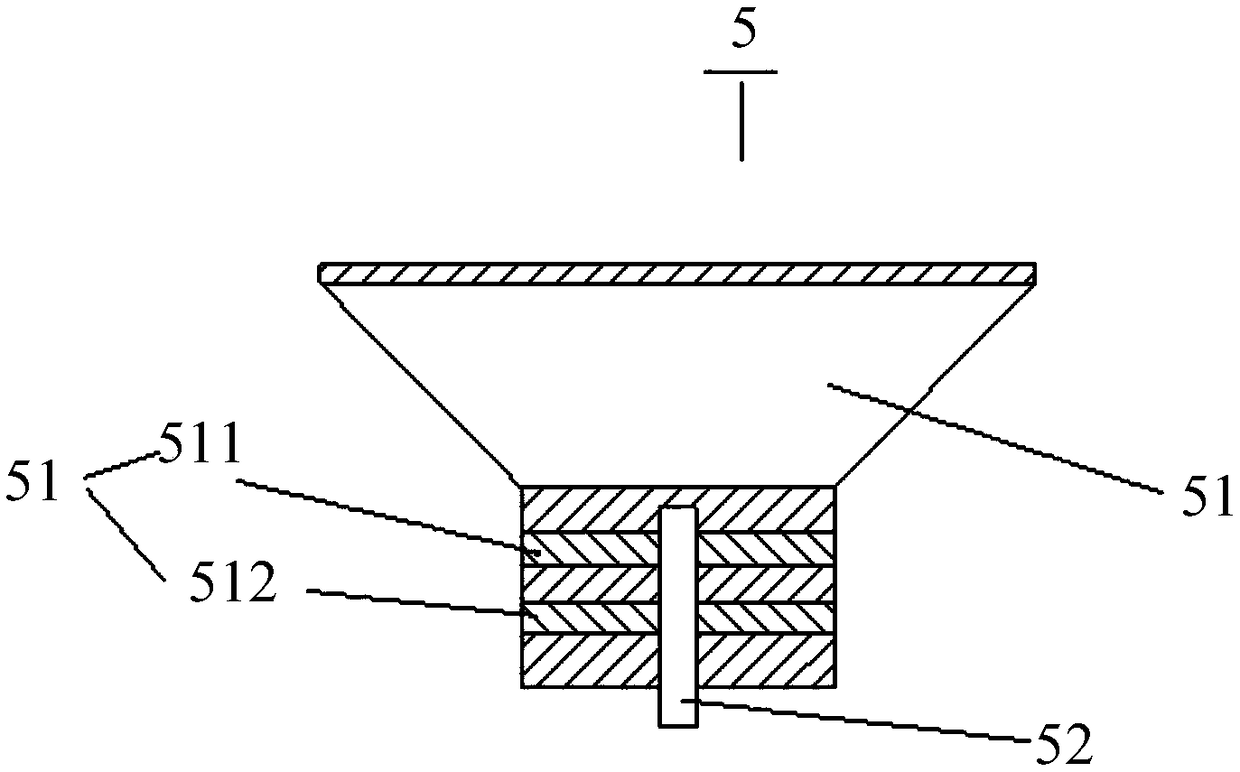

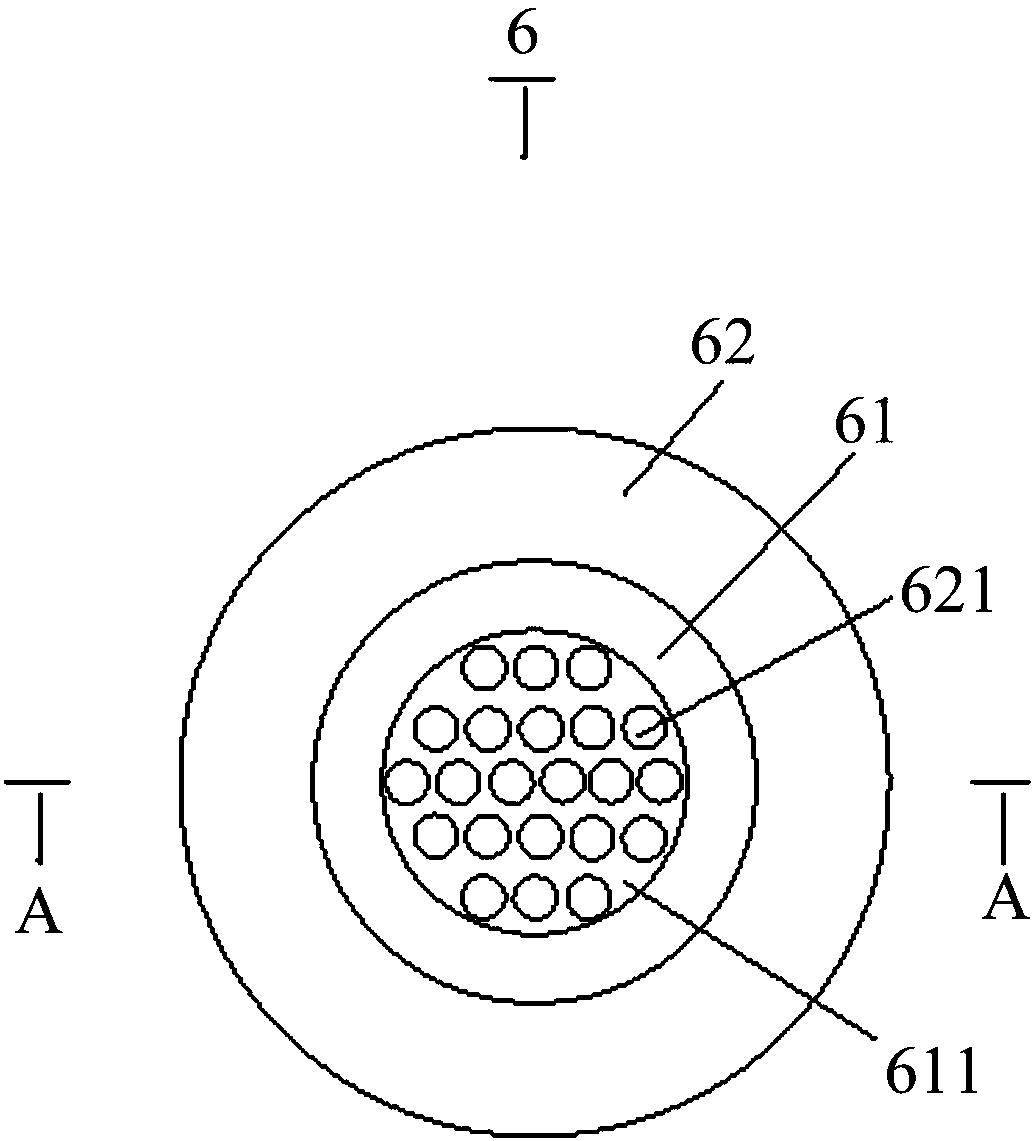

[0070] see figure 1 , which is a schematic structural diagram of an ultrasonic atomization control circuit for e-liquid provided by this application, as shown in figure 1 As shown, an ultrasonic atomization control circuit for e-liquid may include: an MCU chip 1 , a power supply device 2 , a first drive circuit 3 and a second drive circuit 4 . The MCU chip 1 is connected to the first drive circuit 3 and the second drive circuit 4 , the MCU chip 1 is connected to the power supply device 2 , and the first drive circuit 3 and the second drive circuit 4 are respectively connected to the power supply device 2 .

[0071] The power supply device 2 can provide different working voltages for the MCU chip 1 and the first driving circuit 3 , and the power supply device 2 can provide the same working voltage for the first d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com