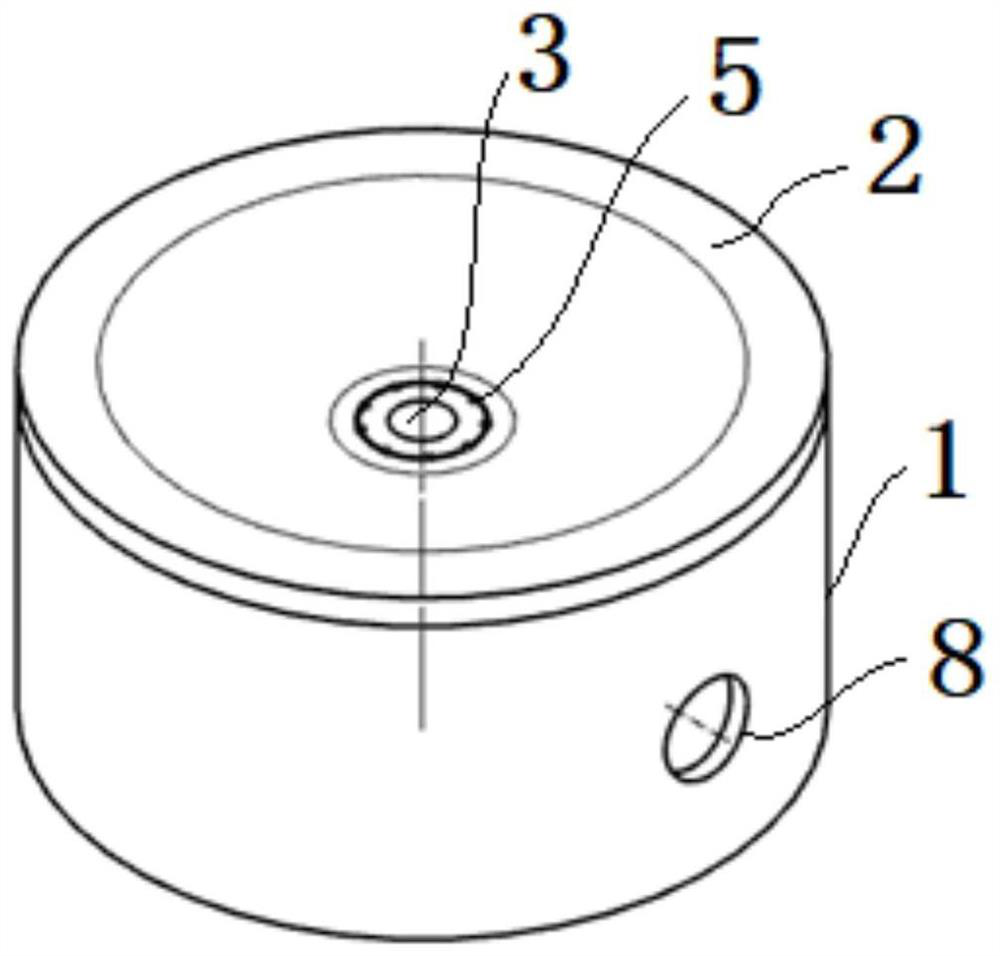

Gas atomizing nozzles and atomizing devices

A gas atomization and nozzle technology, which is applied in the field of gas atomization nozzles and atomization devices, can solve the problems of poor powder sphericity and low atomization efficiency of the atomizer, so as to improve the powder yield and shape, improve the Atomization efficiency, the effect of reducing gas energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

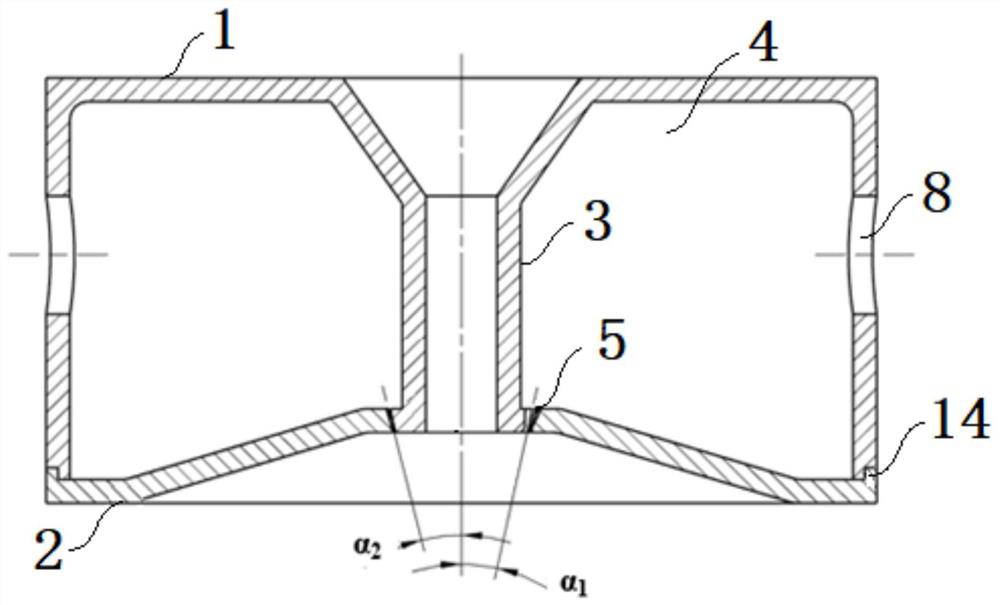

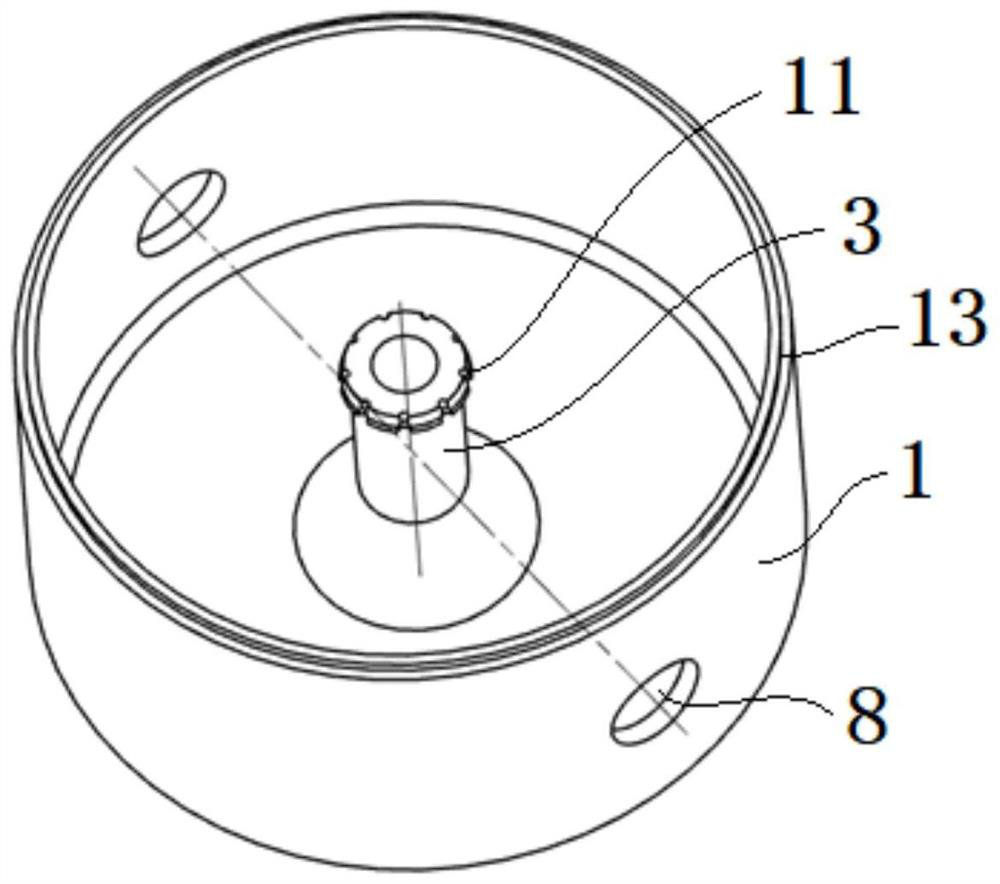

[0044] During operation, the distance between the center line of the annular hole and the center line of the annular slit between the position of the bottom end of the inner wall of the upper end cover of the atomizer cavity and the lower end cover of the cavity is 1 mm. The number of ring holes between the bottom end of the inner wall of the upper end cover of the cavity and the lower end cover of the cavity is 9, the minimum diameter of the hole is 2mm, the minimum width of the annular slit is 1.5mm, and the angle between the center line of the ring hole is α 1 =25°, the angle between the center line of the annular slit is α 2 =30°. The diversion diameter is 4mm. The metal to be atomized is 100Kg of 18Ni300 die steel. The 18Ni300 die steel material is subjected to vacuum induction melting and then atomized. During atomization, the atomizing gas is argon, and the atomizing pressure is 2.5MPa. Continuously successfully atomized 6 furnaces; -200 mesh metal powder accounts f...

Embodiment 2

[0046] During operation, the distance between the center line of the annular hole and the center line of the annular slit between the position of the bottom end of the inner wall of the upper end cover of the atomizer cavity and the lower end cover of the cavity is 0mm. The number of ring holes between the bottom end of the inner wall of the upper end cover of the cavity and the lower end cover of the cavity is 9, the minimum diameter of the hole is 2mm, the minimum width of the annular slit is 1.5mm, and the angle between the center line of the ring hole is α 1 =25°, the angle between the center line of the annular slit is α 2 = 25°. The diversion diameter is 4mm. The metal to be atomized is 100Kg of 18Ni300 die steel. The 18Ni300 die steel material is subjected to vacuum induction melting and then atomized. During atomization, the atomizing gas is argon, and the atomizing pressure is 2.5MPa. Continuously successfully atomized 6 furnaces; -200 mesh metal powder accounts f...

Embodiment 3

[0048] During operation, the distance between the center line of the annular hole and the center line of the annular slit between the position of the bottom end of the inner wall of the upper end cover of the atomizer cavity and the lower end cover of the cavity is 1 mm. The number of ring holes between the bottom end of the inner wall of the upper end cover of the cavity and the lower end cover of the cavity is 9, the minimum diameter of the hole is 2mm, the minimum width of the annular slit is 1.5mm, and the angle between the center line of the ring hole is α 1 =20°, the angle between the center line of the annular slit is α 2 = 25°. The diversion diameter is 4mm. The metal to be atomized is 100Kg of 18Ni300 die steel. The 18Ni300 die steel material is subjected to vacuum induction melting and then atomized. During atomization, the atomizing gas is argon, and the atomizing pressure is 3MPa. Continuously successfully atomized 6 furnaces; -200 mesh metal powder accounts fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com