Atomizing combustor for treating industrial hazardous waste liquid

A burner and dangerous technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of excessive discharge of harmful substances, incomplete combustion, air pollution, etc., and achieve the effects of reducing hazards, facilitating operation, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

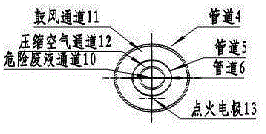

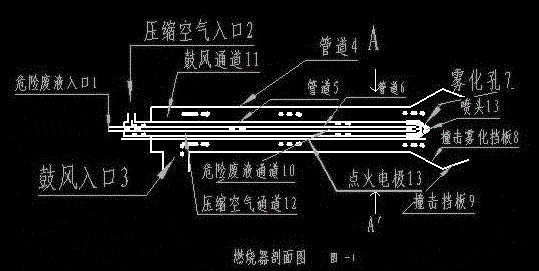

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] An atomizing burner for disposing of industrial hazardous waste liquid includes pipeline 4, pipeline 5, pipeline 6, hazardous waste liquid inlet 1, compressed air inlet 2, blast inlet 3, nozzle 13, impact atomization baffle 8, impact baffle Plate 9, ignition circuit 13, three pipes, with different diameters and different lengths, are concentrically nested together, shortened from the inside to the outside, forming three independent channels, hazardous waste liquid channel 10, compressed air channel 12, and blast channel 11 When igniting and burning, start the blower, blow air to the front end of the burner through the blast inlet 3, start to adjust the damper to be smaller, which is conducive to ignition, and provide waste to the burner nozzle 13 through the hazardous waste liquid inlet 1 after combustion Liquid, and then provide high-pressure air to the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com