Closed loop control method for indoor wind wave water tank wave maker

A closed-loop control and wave generator technology, which is applied in computer control, program control, general control system, etc., can solve the problems such as the difficulty of direct reflection and monitoring of wave-making wave and wind effect, poor closed-loop control effect, and single application. The control principle is safe and reliable, the closed-loop control effect is good, and the degree of automation is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

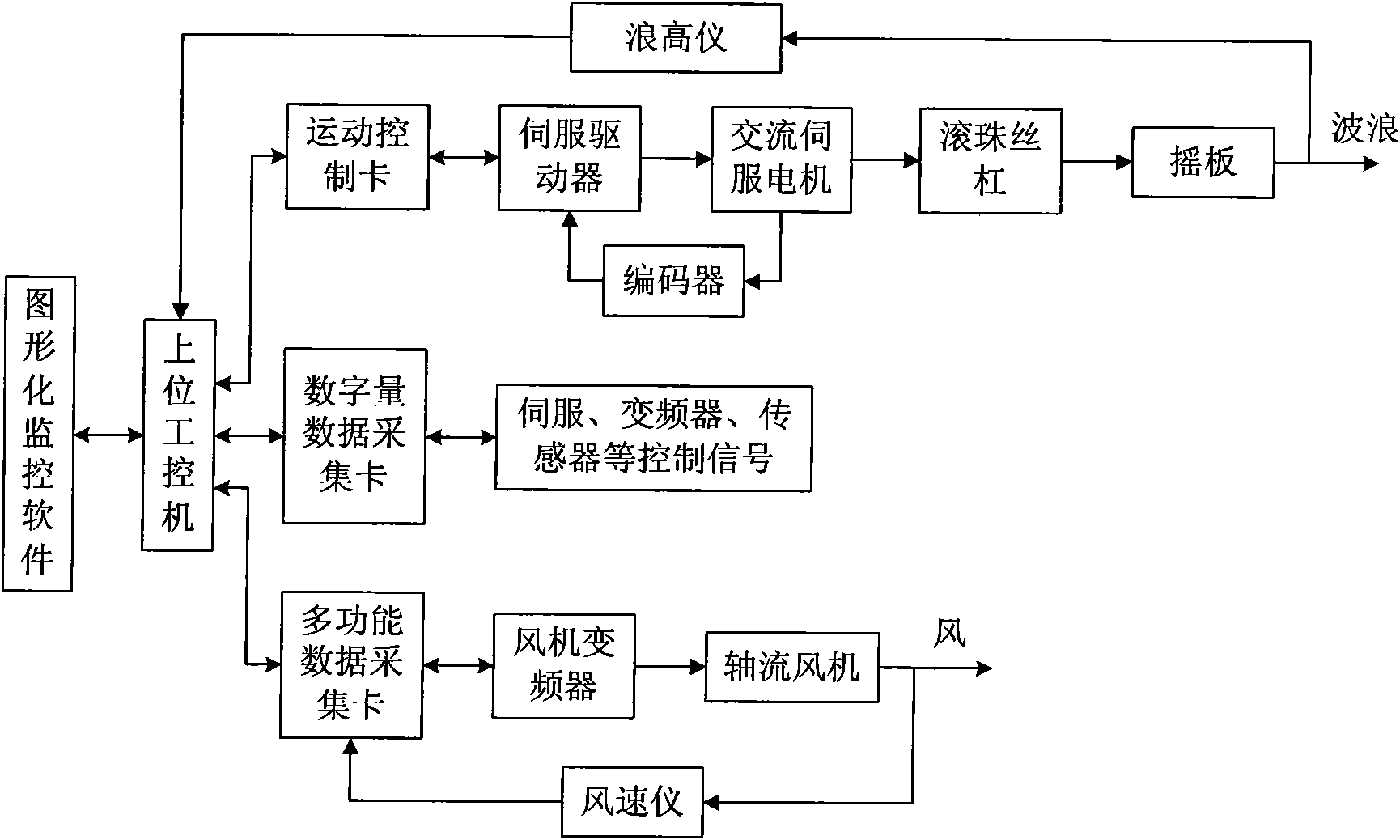

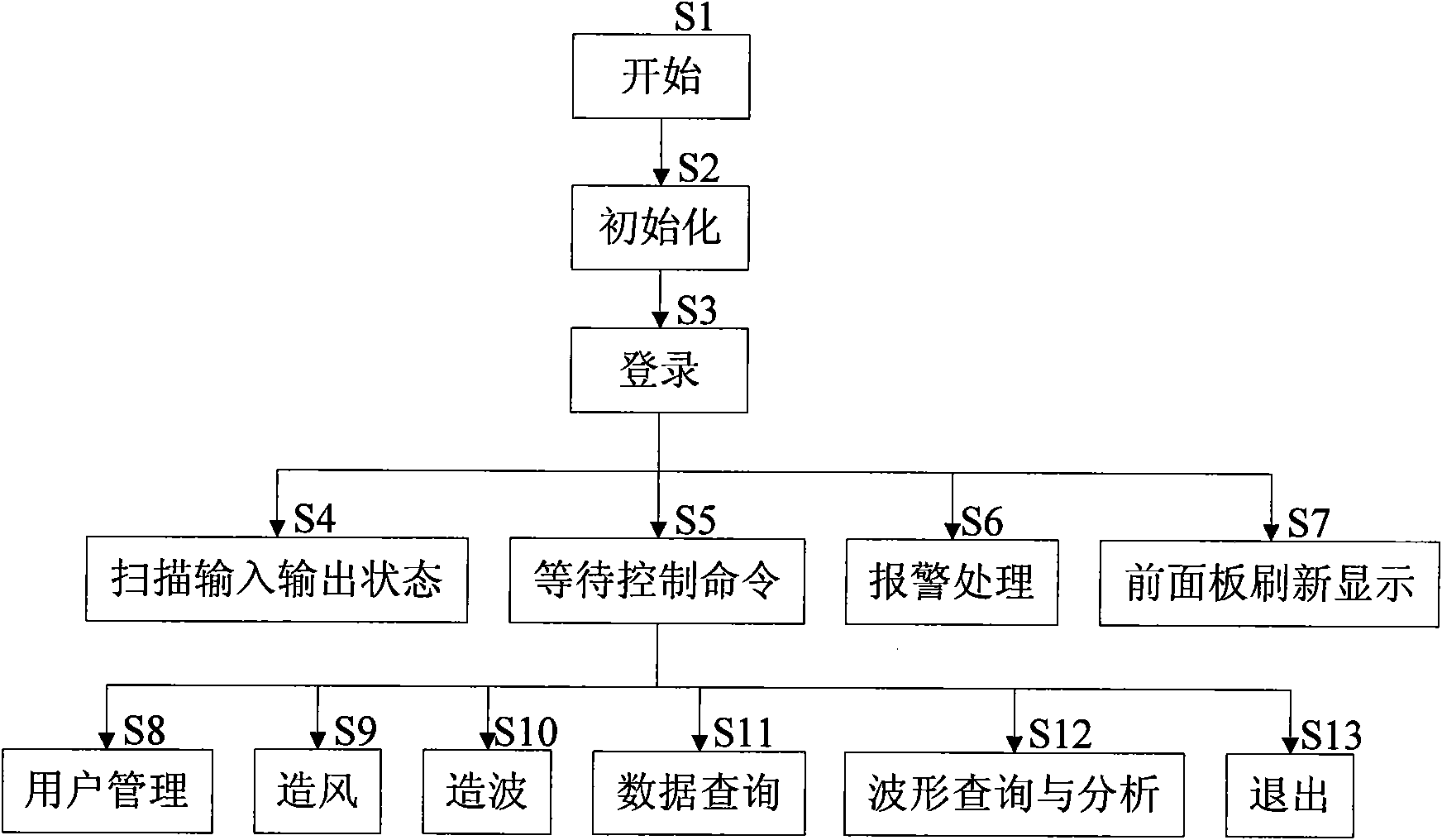

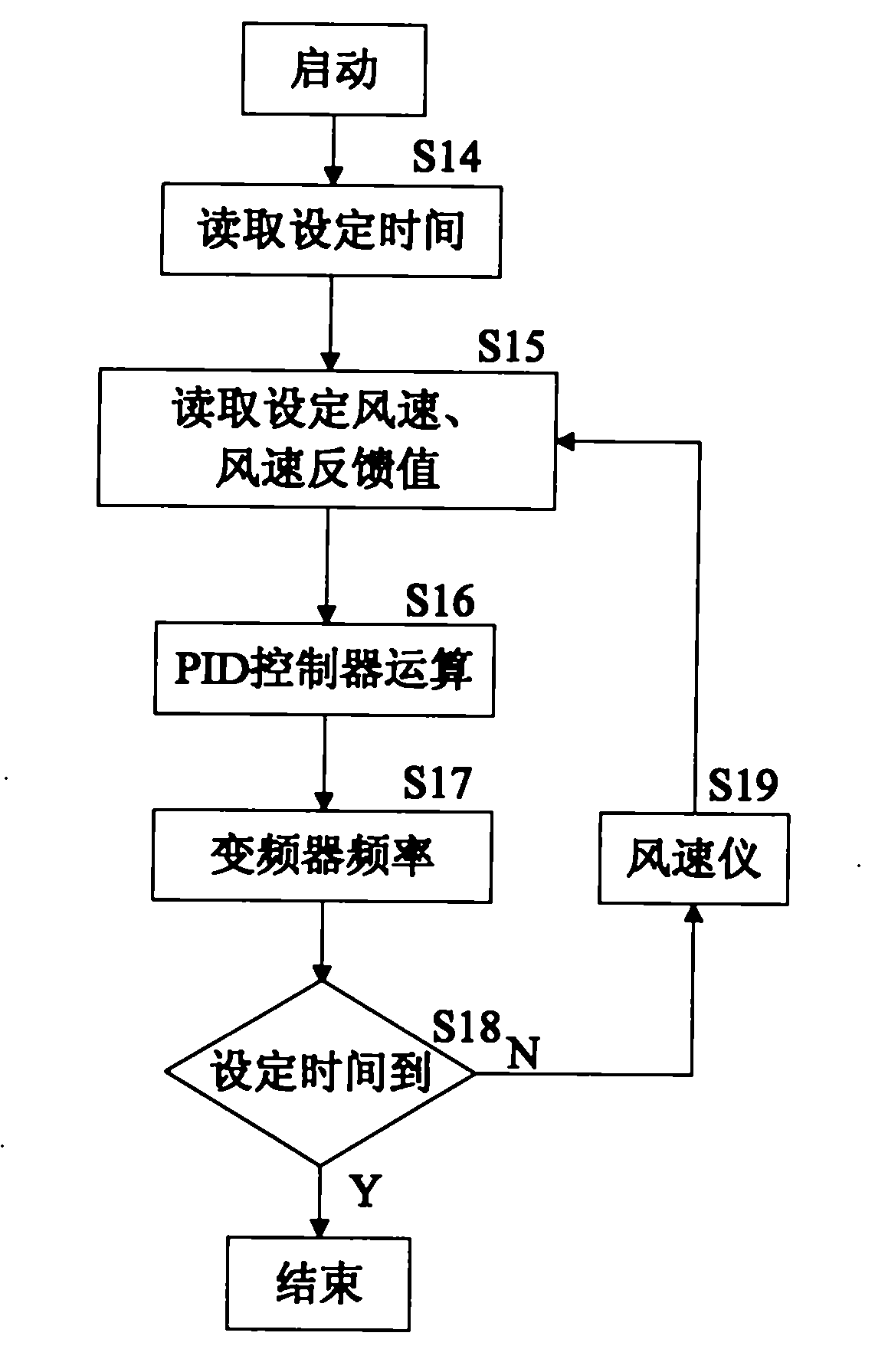

[0019] In this embodiment, the real-time collection of wave height data by the wave height meter is used as the feedback signal of the wave-making control to form the closed-loop control of the shaking plate wave-making; the real-time measurement of the wind speed in the air duct by the anemometer is used as the feedback signal of the wind-making control to form the closed-loop control of the wind-making wind. ; Form a closed-loop control system that creates shallow water waves and capillary waves through wind-making; the system device that realizes closed-loop control includes a host computer monitoring module, a wave-making module and a wind-making module; the host computer monitoring module is installed for virtual instrument testing and measurement The industrial computer of the software; the upper computer monitoring module is the monitoring and control center of the entire closed-loop control system of the wave generator, including system initialization, wave-making contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com