Online continuous detecting device of butylbenzene rubber reaction converting rate and calculating method thereof

A technology of reaction conversion rate, styrene-butadiene rubber, applied in measuring device, specific gravity measurement, determination of specific gravity by measuring pressure difference, etc. control and other issues, to achieve the effect of fast response time, long service life and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical points of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

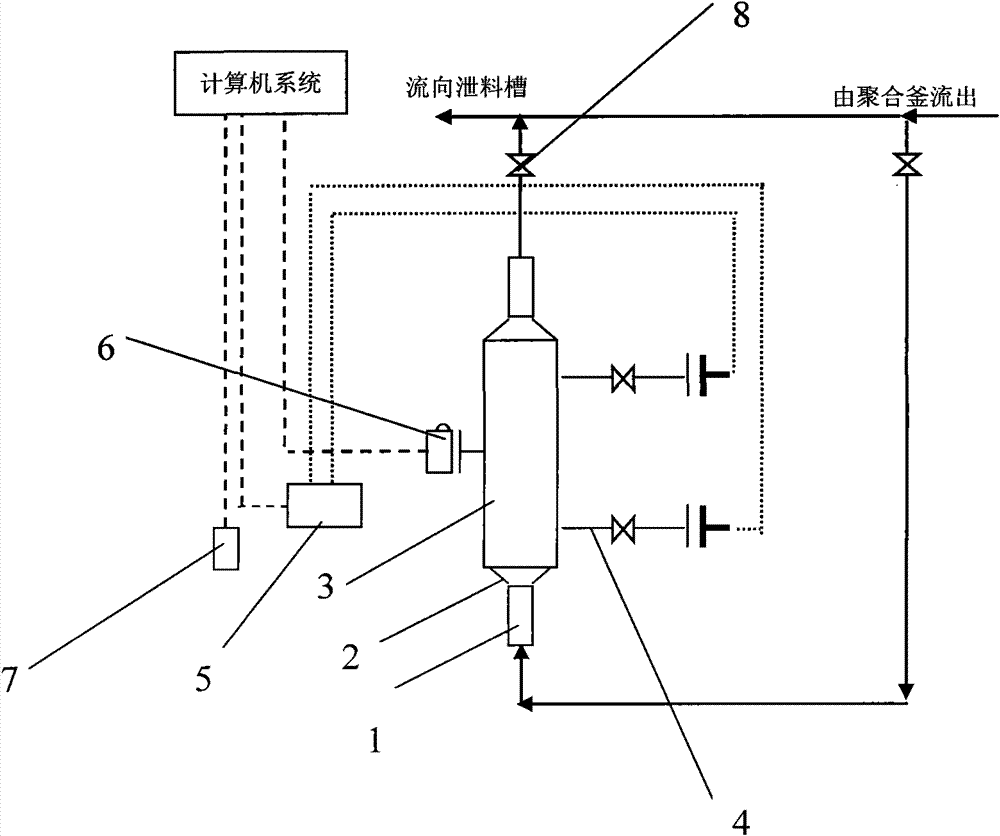

[0032] Such as figure 1 An online continuous detection device for the reaction conversion rate of styrene-butadiene rubber is shown, and a section with a length of 1200mm to 1600mm and a diameter of 300mm to 500mm is installed on the outlet material pipeline of the polymerization reactor of the styrene-butadiene rubber device through the size head 2 and the original glue pipeline 1 The vertical measuring tube 3 of the vertical measuring tube 3, the large end of the large and small head is airtightly connected with the vertical measuring tube 3, and the small end of the large and small head 2 is airtightly connected with the original pipeline 1 of the mucilage; Pressure point, the vertical measuring tube 3 of 200mm to 400mm is reserved at the top and bottom of the two measuring points. The measuring point is connected wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com