Large-amplitude ultrasonic spherical metal powder preparing device and method

A metal powder and preparation device technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor sphericity, large consumption of inert gas particle size distribution range, etc., and achieve narrow distribution, low oxygen content, and good sphericity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

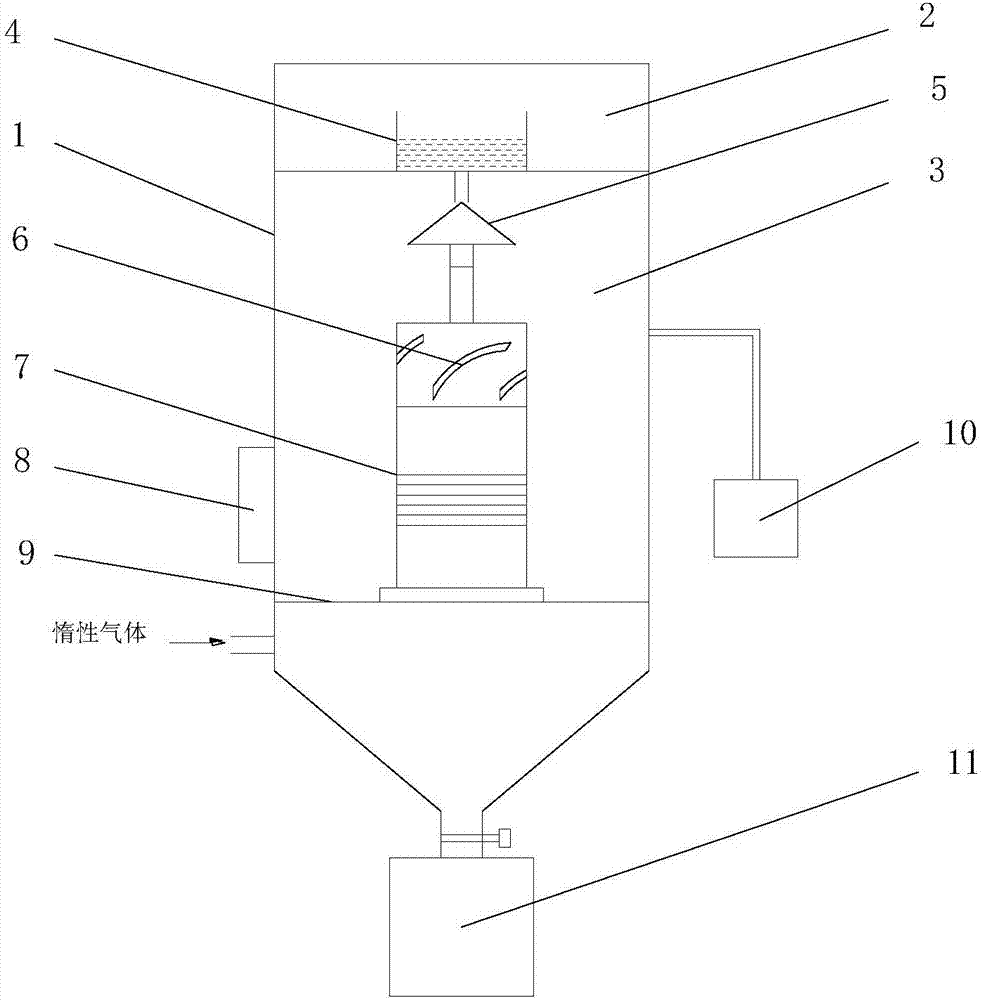

[0035] The preparation method of the spherical metal powder can be realized by the following steps by using the above-mentioned large-amplitude ultrasonic spherical metal powder preparation device:

[0036] (1) After the atomization chamber 3 is evacuated by a vacuum pump, an inert gas is introduced into the atomization chamber 3 from the air inlet;

[0037] (2) Use the ultrasonic generator 8 to convert the input electrical signal into an electrical signal of a specific frequency that matches the transducer 7, drive the transducer 7 to work, and excite the transducer 7 to generate longitudinal stretching vibration, and the longitudinal stretching vibration effect For the slotted horn 6, the four mutually parallel spiral grooves on the wall of the slotted circular tube of the slotted horn 6 are amplified, and the output amplitude is relatively large;

[0038] (3) The molten metal in the melting furnace 4 flows to the umbrella-shaped tool head 5 and forms a thin liquid layer on th...

Embodiment 1

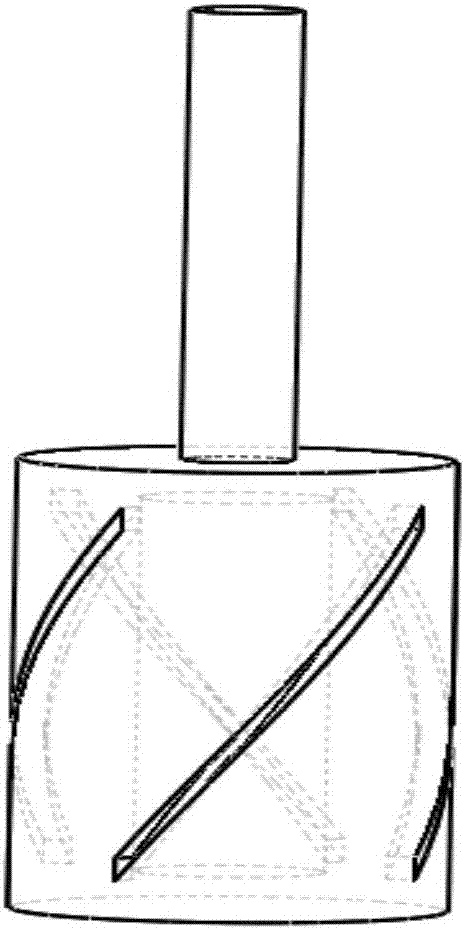

[0040] The piezoelectric crystal stack of the transducer 7 in this embodiment is formed by laminating and pressing six PZT-4 piezoelectric ceramic sheets. The slotted horn 6 is composed of a vibration input section and a vibration output section to form a stepped horn structure; the vibration input section is composed of a slotted round tube, the length of the vibration input section is 59mm, and the vibration output section is 59mm long , 4 spiral grooves parallel to each other are opened on the side wall of the grooved pipe along the circumferential direction. The starting points of the 4 spiral grooves are on the same circumference and are evenly distributed on the pipe wall. The distance between the ends of the slotted round tube is equal, the outer diameter of the slotted round tube is 40mm, the inner diameter is 18mm, the pitch of the spiral groove is 184mm, the groove width is 3mm, the groove depth is 3mm, and the helix angle is 63.7°. The umbrella tip cone angle of the...

Embodiment 2

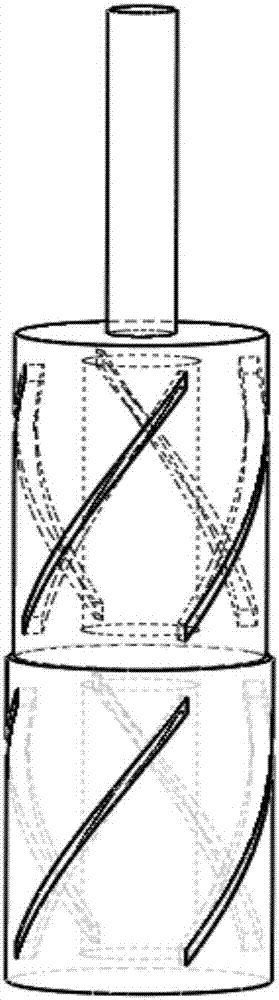

[0042] The piezoelectric crystal stack of the transducer 7 in this embodiment is formed by laminating and pressing four PZT-4 piezoelectric ceramic sheets. The slotted horn 6 is composed of a vibration input section and a vibration output section to form a stepped horn structure. The total length of the vibration input section is 118mm, and the length of the vibration output section is 29.5mm; see image 3 , the vibration input section is composed of two slotted round tubes connected in series. The diameter difference between one slotted round tube and the adjacent slotted round tube is 2mm. 4 spiral grooves parallel to each other, the starting points of the 4 spiral grooves are on the same circumference, and are evenly distributed on the pipe wall, the distance between the beginning and end of the spiral grooves is equal to the two ends of the grooved pipe, and the pitch of the spiral grooves Both are 184mm, the groove width is 3mm, and the groove depth is 3mm. The helix angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com