Liquid surface tension testing method based on mechanical vibration of liquid droplet

A liquid surface tension and mechanical vibration technology, applied in the field of liquid physical and chemical properties measurement, can solve the problems of error-prone, time-consuming, cumbersome calculations, etc., and achieve the effect of low equipment cost, less reagent consumption, and high cost performance of the instrument

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

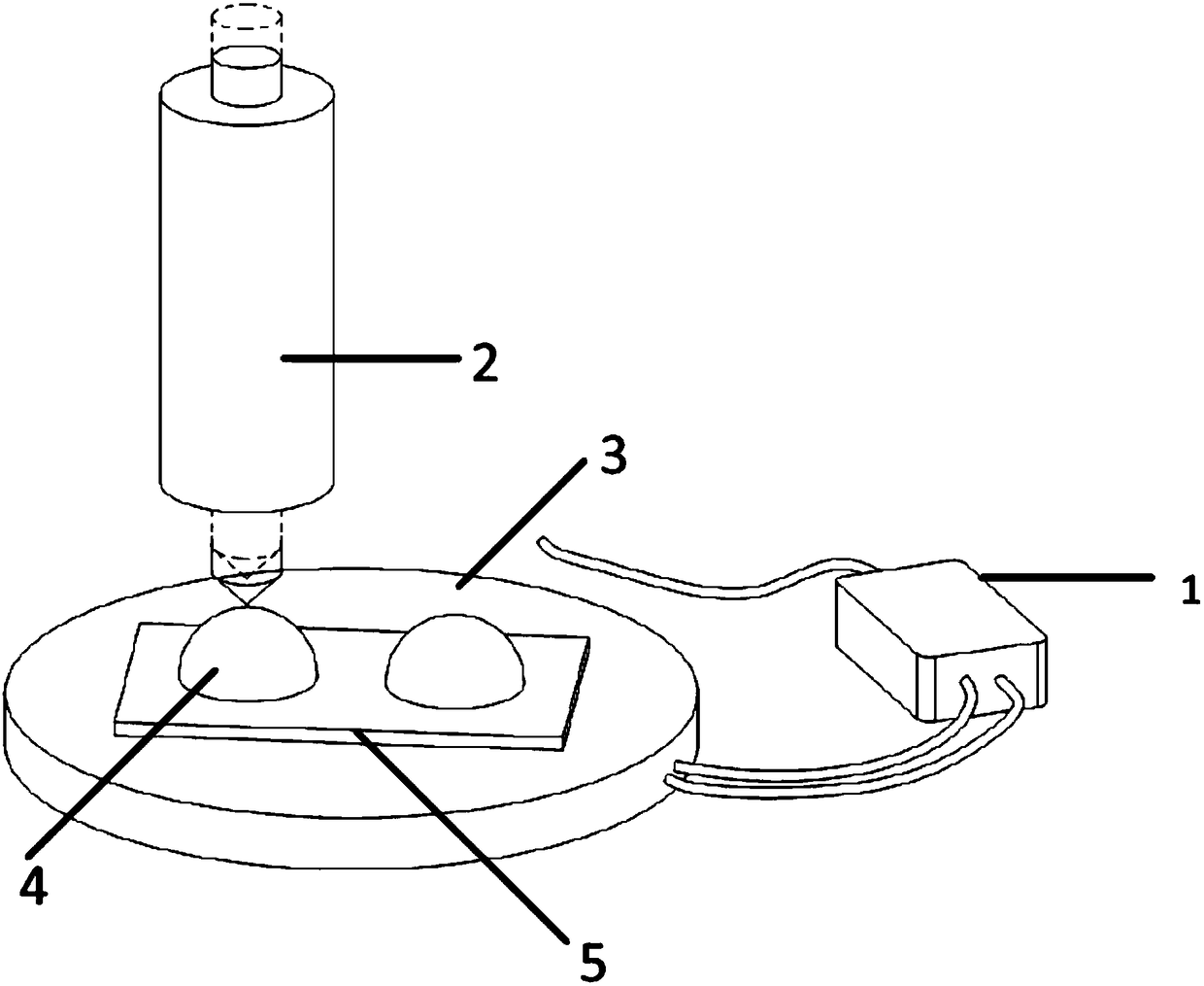

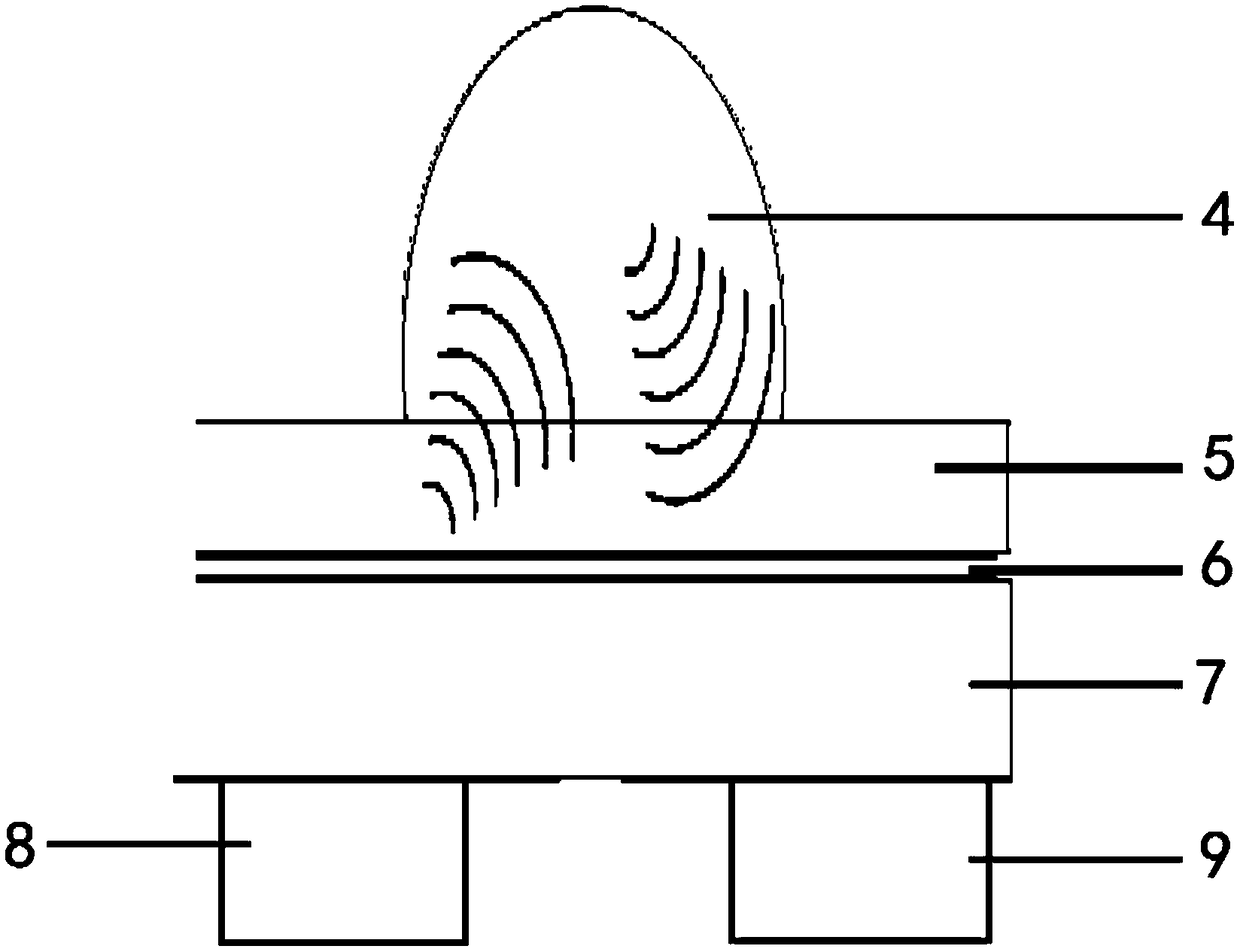

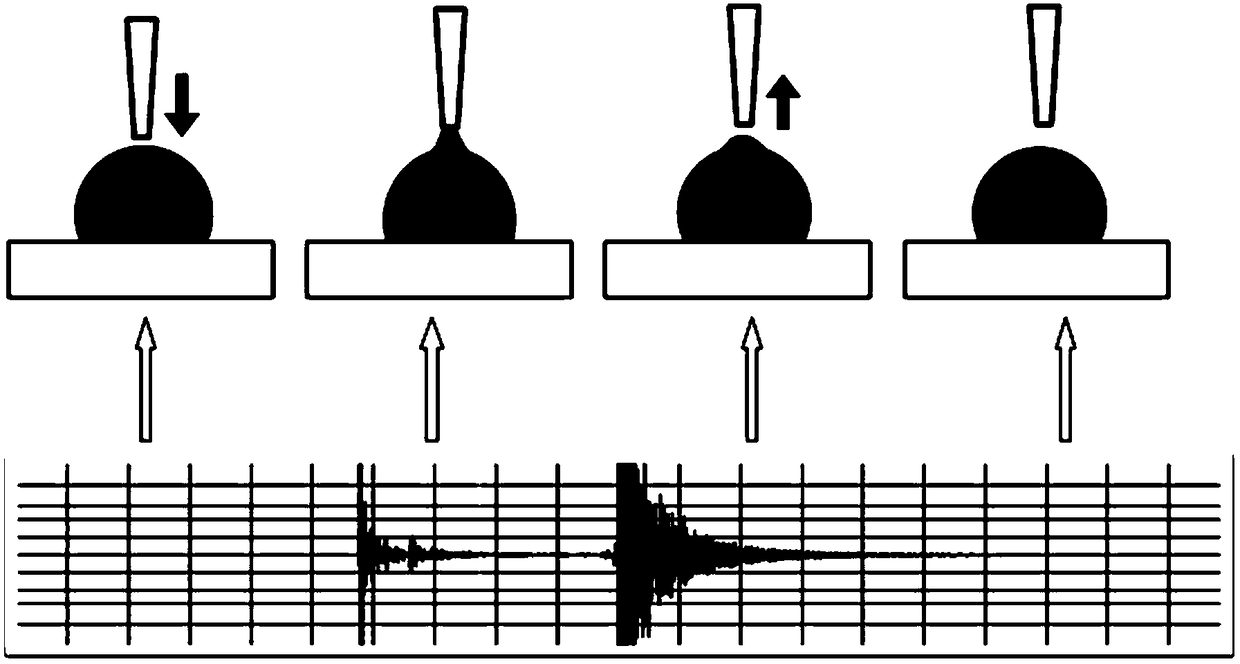

[0033] Such as figure 1 , 2 As shown, the equipment used in the present invention includes a vibration triggering device 2, which is composed of an ultrasonic input module, a reflected ultrasonic detection module, and a signal demodulation module together to form the ultrasonic probe 3 of the Doppler ultrasonic instrument, and the ultrasonic probe 3 is connected to the Doppler ultrasonic instrument Switch 1, the hydrophobic substrate 5 is placed on the upper part of the ultrasonic probe, the micro-injector and the vibration trigger device 2 with a tip are arranged on the upper part of the hydrophobic substrate 5. The micro-injector produces droplets 4 with a mass of 5-20 mg, and the tip of the vibration trigger device It is made of polytetrafluoroethylene, where the vibration trigger device 2 is specifically composed of a steel shell and a spring, the tip diameter of the polytetrafluoroethylene material is 100 microns, and a coupling gel layer 6 is provided between the hydrophob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com