Method of ionizing a liquid and an electrostatic colloid thruster implementing such a method

a technology of electrostatic colloid and liquid ionization, which is applied in the direction of plasma technique, mechanical apparatus, machines/engines, etc., can solve the problems of jet eventually becoming unstable, separating into charged droplets, and a potential space mission being deemed infeasible,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

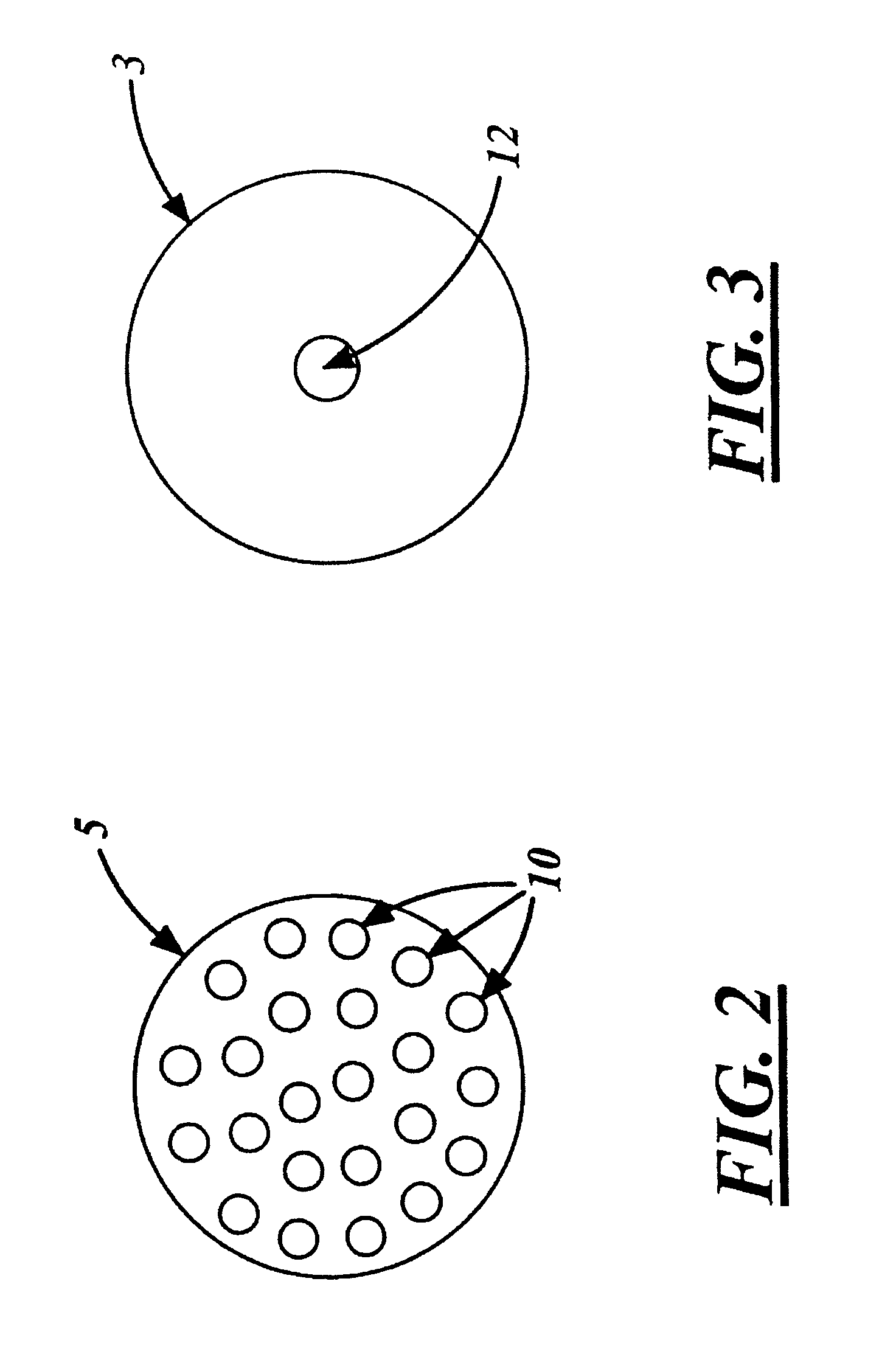

ergoing various stages of deformation while on the atomization surface of FIG. 3 and during a time period wherein an electrically charged droplet is being extracted therefrom for propulsion of the electrostatic colloid thruster in FIG. 1.

[0022]FIG. 5 is a sectional illustration of a standing capillary wave on the atomization surface of FIG. 3. In this illustration, the standing capillary wave is set forth within a two-dimensional coordinate system for the purpose of analysis.

DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

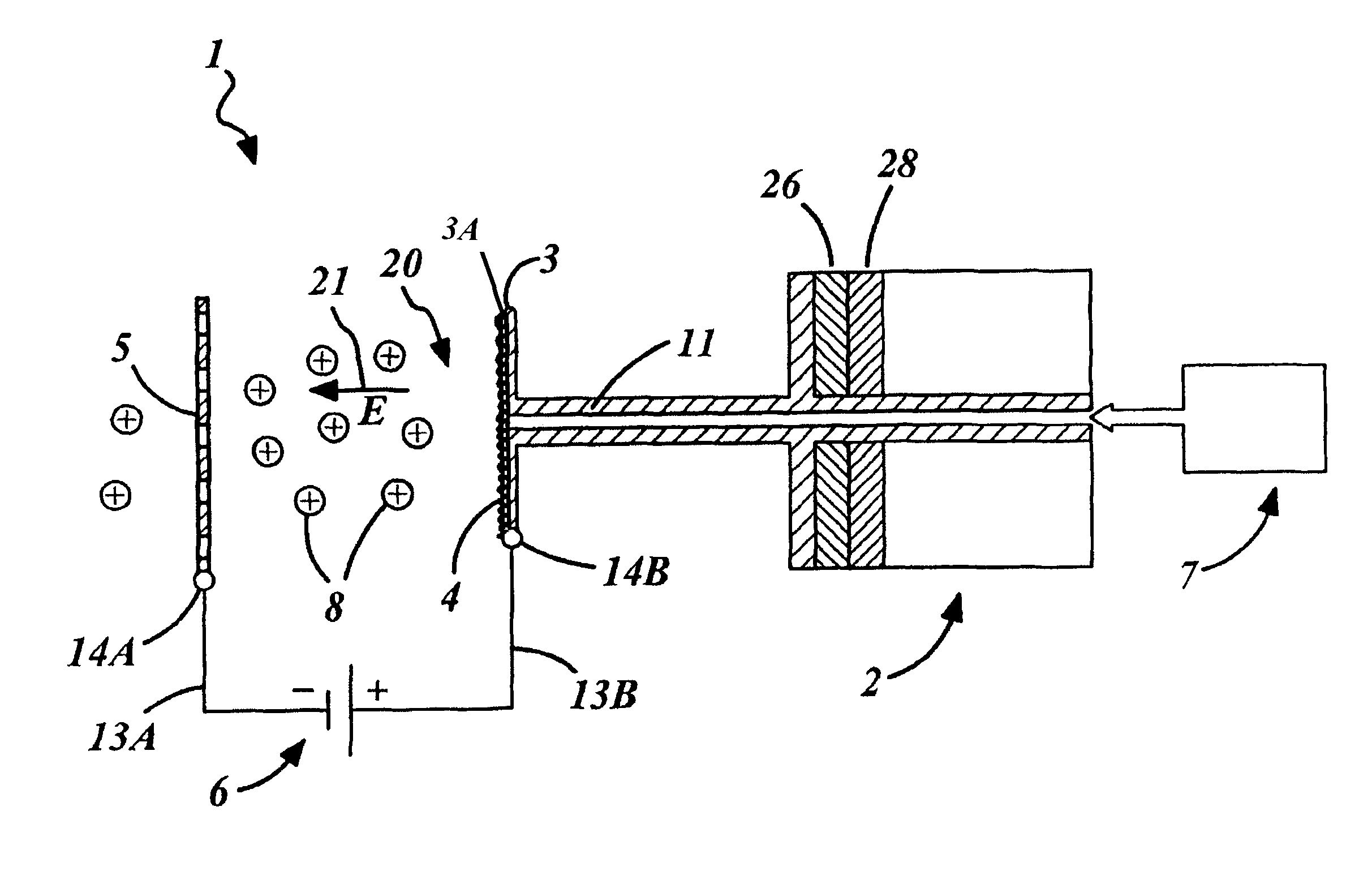

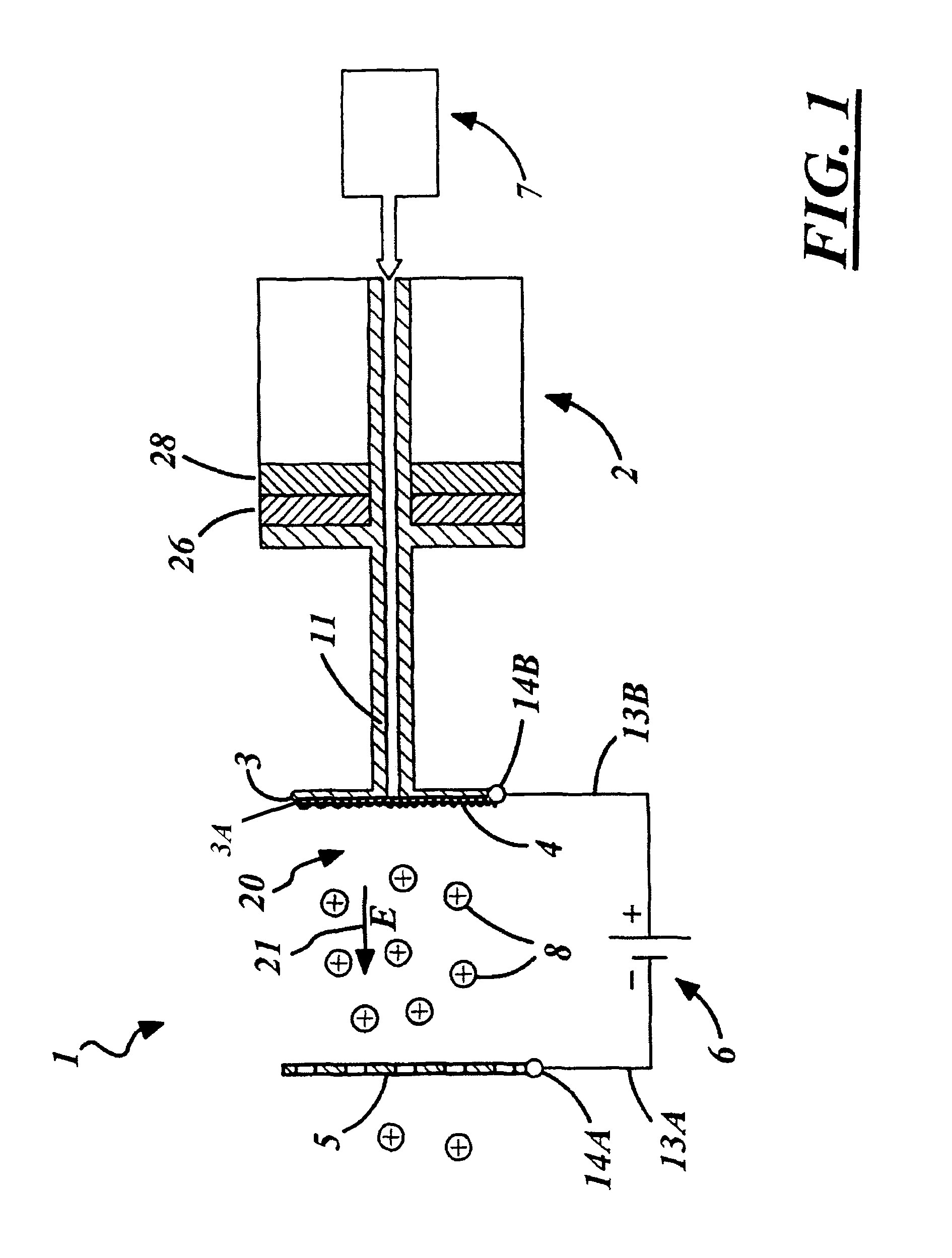

[0023]FIG. 1 is a system diagram illustrating one practicable embodiment of an electrostatic colloid thruster 1 pursuant to the present invention. In general, operation of the thruster 1 is based on a novel modification of electrospray technology that is capable of producing large quantities of uniformly charged droplets or particles for the high-performance propulsion of spacecraft in and through space. As shown in FIG. 1, the electrostatic colloid thruster 1 bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conductivity | aaaaa | aaaaa |

| conductivity | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com