Titanium alloy piston and connecting rod set applied to diesel locomotive and process method

A technology of piston connecting rod and process method, which is applied in the field of rail transit, can solve the problems of low elastic modulus and yield strength of aluminum parts, affect life, and poor anti-corrosion performance, and achieve long service life, uniform force, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

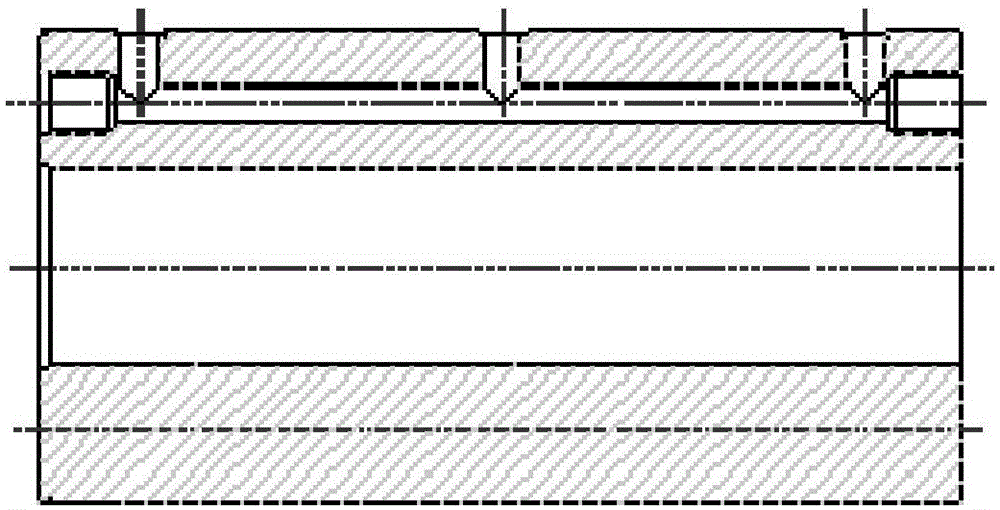

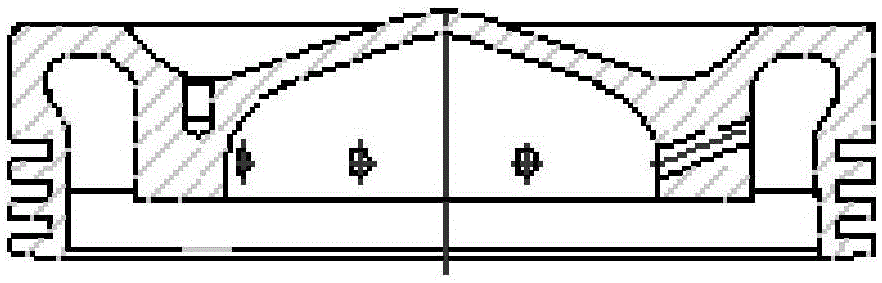

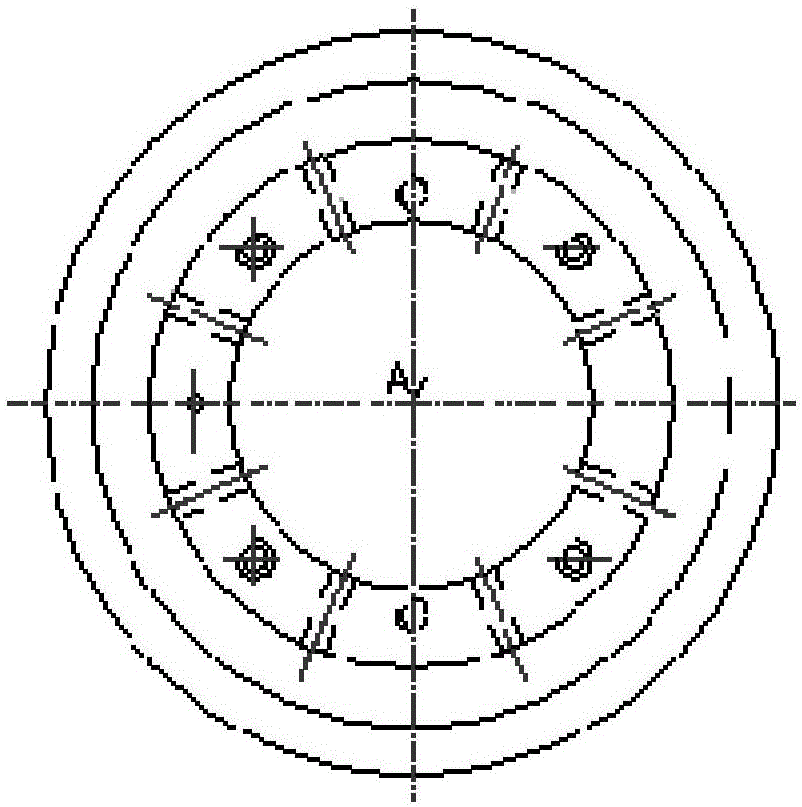

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0046] A titanium alloy used to manufacture a piston connecting rod group. In order to prevent friction and wear between dissimilar metals, the parts of the piston connecting rod group use the same titanium alloy raw material. The performance indicators of the titanium alloy material are shown in Table 4:

[0047]

[0048] Table 4

[0049] Titanium alloy by mass percentage is:

[0050] The Al content is 5.5-6.5%, the Mo content is 0.5-1.5%, the V content is 3.5-4.5%, the Fe content is less than 0.25%, the O content is less than 0.15%, and the balance is Ti.

[0051] Titanium alloy by mass percentage is:

[0052] The Al content is 5.8-6.2%, the Mo content is 0.8-1.2%, the V content is 3.8-4.2%, the Fe content is less than 0.25%, the O content is less than 0.15%, and the balance is Ti.

[0053] Titanium alloy by mass percentage is:

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap