Wind turbine cooling system and wind turbine

A technology for wind turbines and cooling systems, applied in wind turbines, wind energy power generation, engines, etc., can solve problems such as failure to achieve cooling effect, over-temperature failure of heating components, insufficient air volume, etc., to improve air supply adaptability, guarantee The effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

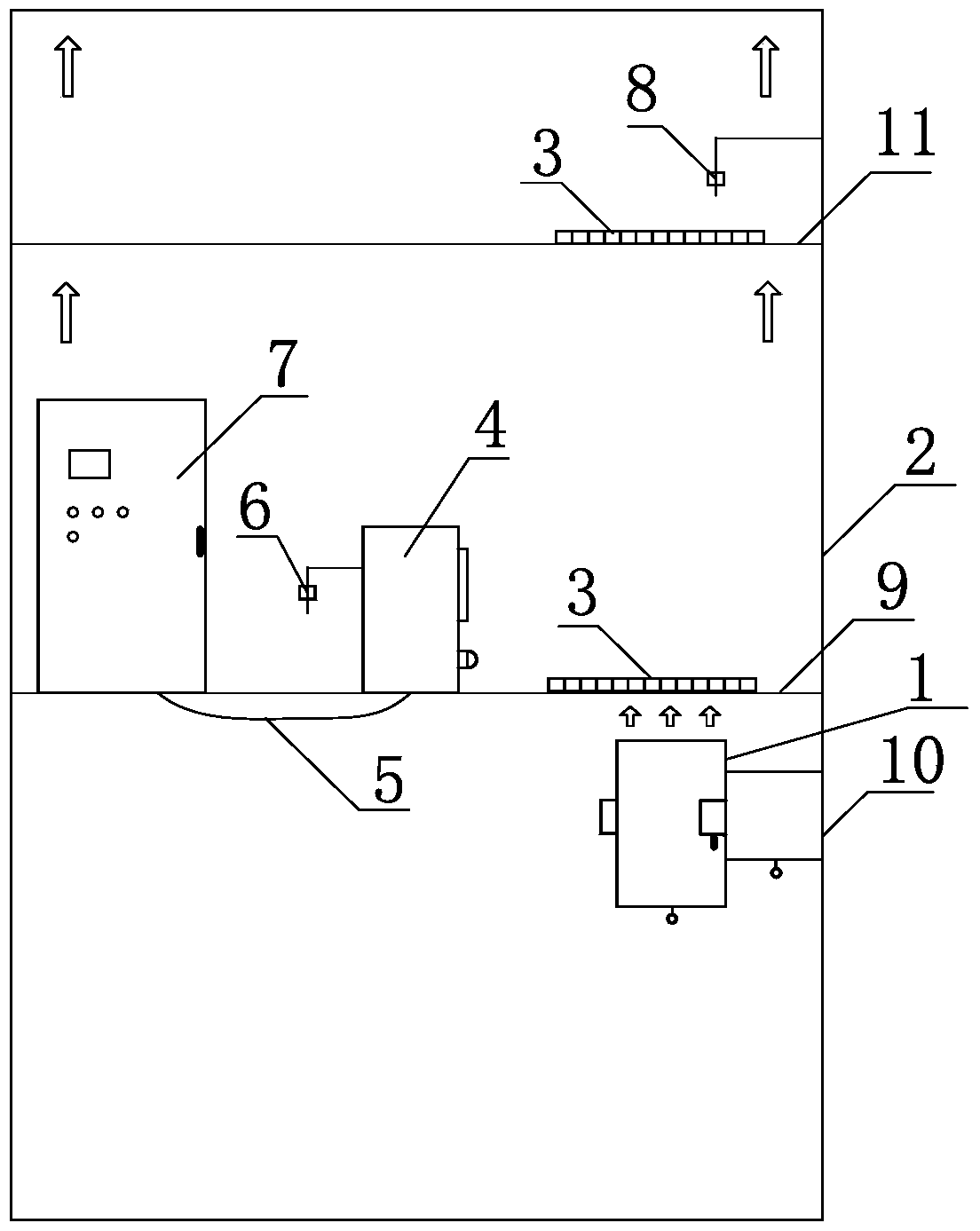

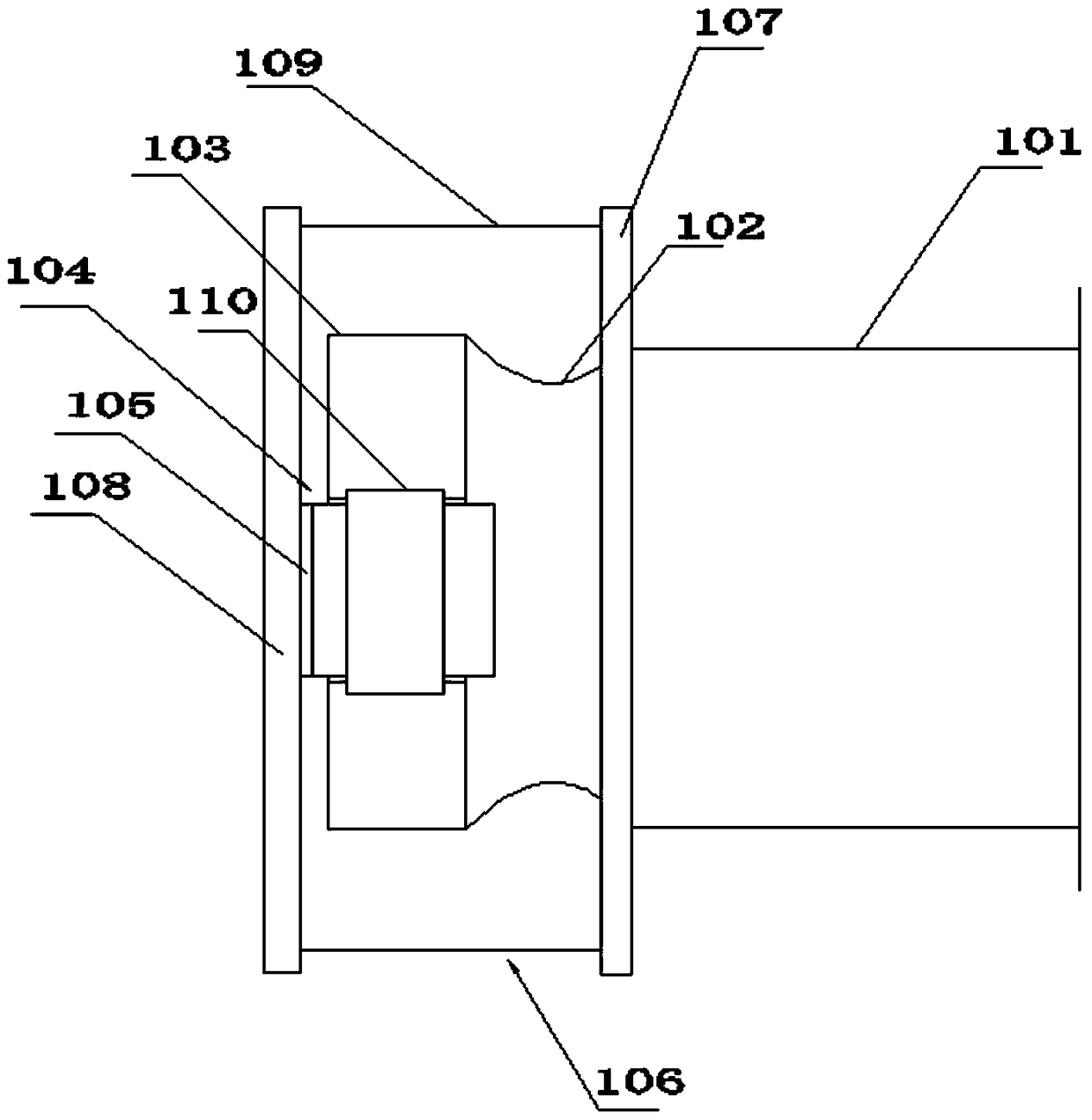

[0025] Such as figure 1 As shown, the heat dissipation system of the wind power generating set in this embodiment includes an air inlet 10, a centrifugal fan 1 and a control system.

[0026] The air inlet 10 is arranged on the wall of the tower tube 2 of the wind power generating set, and the centrifugal fan 1 communicates with the air inlet 10, and the low-temperature air from the outside is introduced into the tower tube 2 through the air inlet 10 through the centrifugal fan 1 to reduce the heat generation of the wind power generating set. The components are cooled by heat dissipation. Both the centrifugal fan 1 and the air inlet 10 can be connected through the air guide pipe, and the centrifugal fan 1 can be arranged near the air inlet 10, so that the air flow between the centrifugal fan 1 and the air inlet 10 can be controlled. Let's say it's connected.

[0027] The control system includes a main control system 7 for controlling the centrifugal fan 1, a temperature senso...

Embodiment 2

[0047] This embodiment provides a wind power generating set, which includes the heat dissipation system for the whole machine according to Embodiment 1.

[0048] The structure, principle and beneficial effects of the cooling system for the whole machine are as described in the first embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com