Shock absorber

A shock absorber and protrusion technology, applied in the field of vibration reduction, can solve the problems of easy shaking, limited contact area, and limited shear force, so as to improve the high-speed speed of the fan blade and reduce the risk of detachment Possibility, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

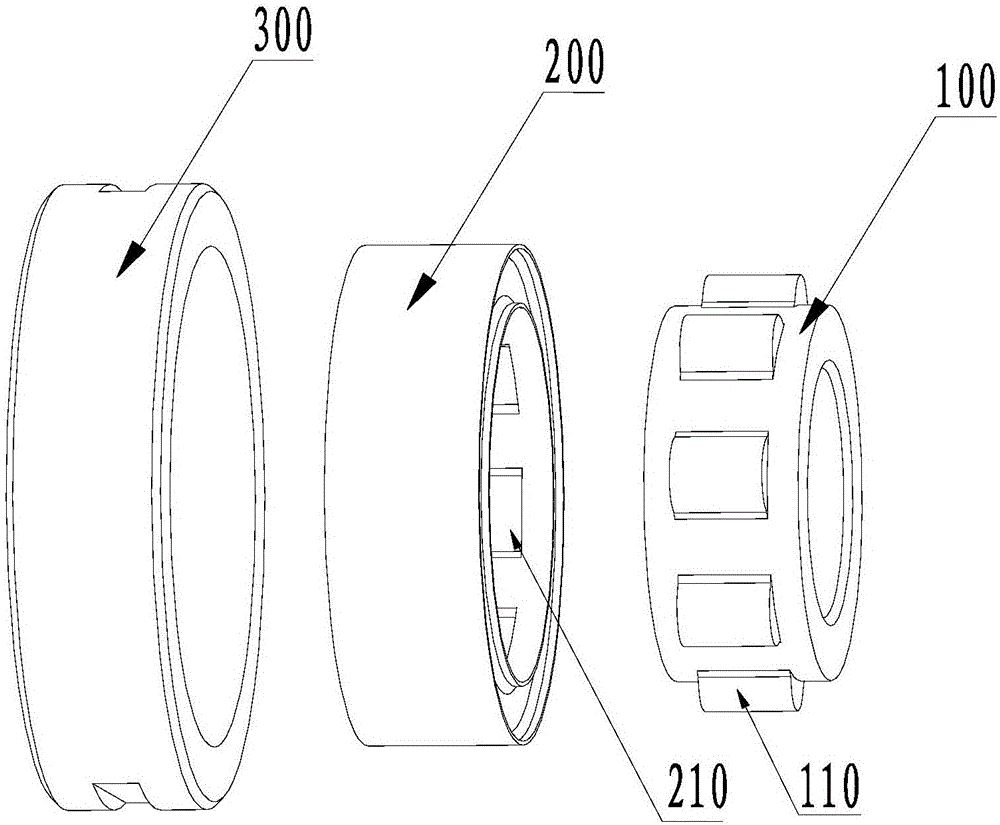

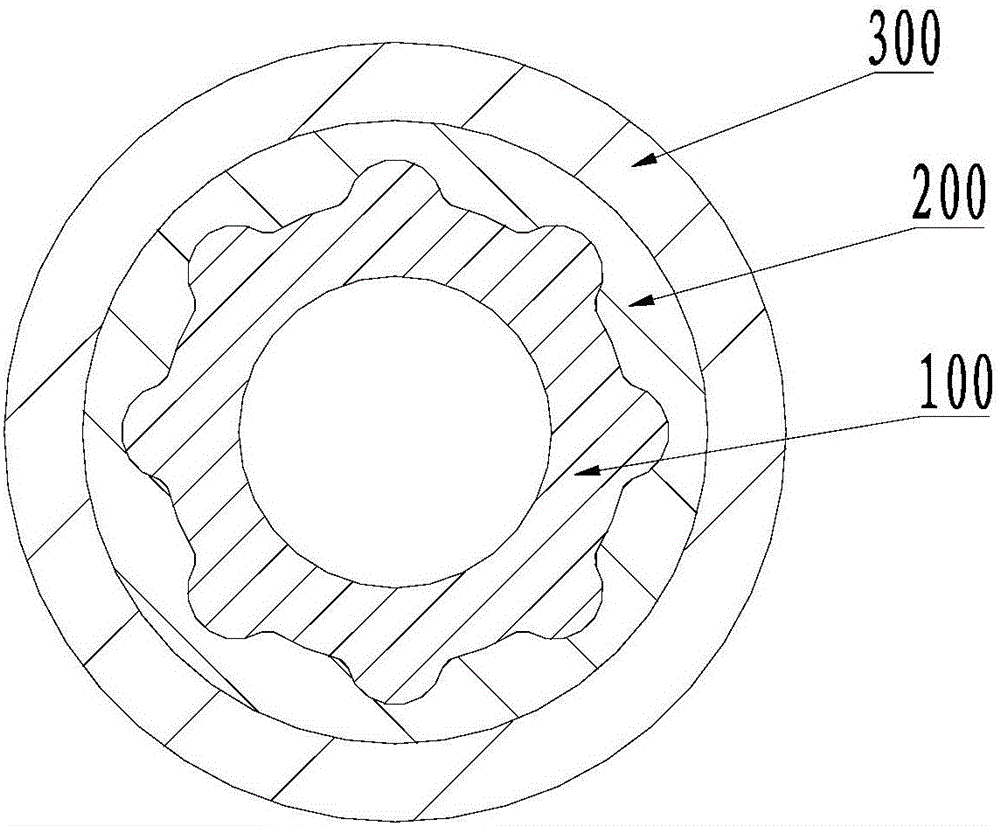

[0054] Such as figure 1 with figure 2 As shown, as a possible implementation mode, a plurality of first protrusions 110 are evenly provided on the outer surface of the inner sleeve 100, and a plurality of first protrusions 110 are arranged on the inner surface of the middle layer 200 one by one. Corresponding to the second groove 210 , the first protrusion 110 is embedded in the second groove 210 . In this way, the contact area between the inner sleeve 100 and the middle layer 200 is increased, and when the shock absorber is subjected to torque during operation, the possibility of the inner sleeve 100 being separated from the middle layer 200 is reduced, and the shock absorber’s bearing capacity is improved. The ability of the wind blade to rotate at a high speed improves the reliability of the shock absorber.

[0055] Of course, the first protrusion 110 provided on the outer surface of the inner sleeve 100 can also be an annular boss concentrically arranged on the outer pe...

Embodiment 2

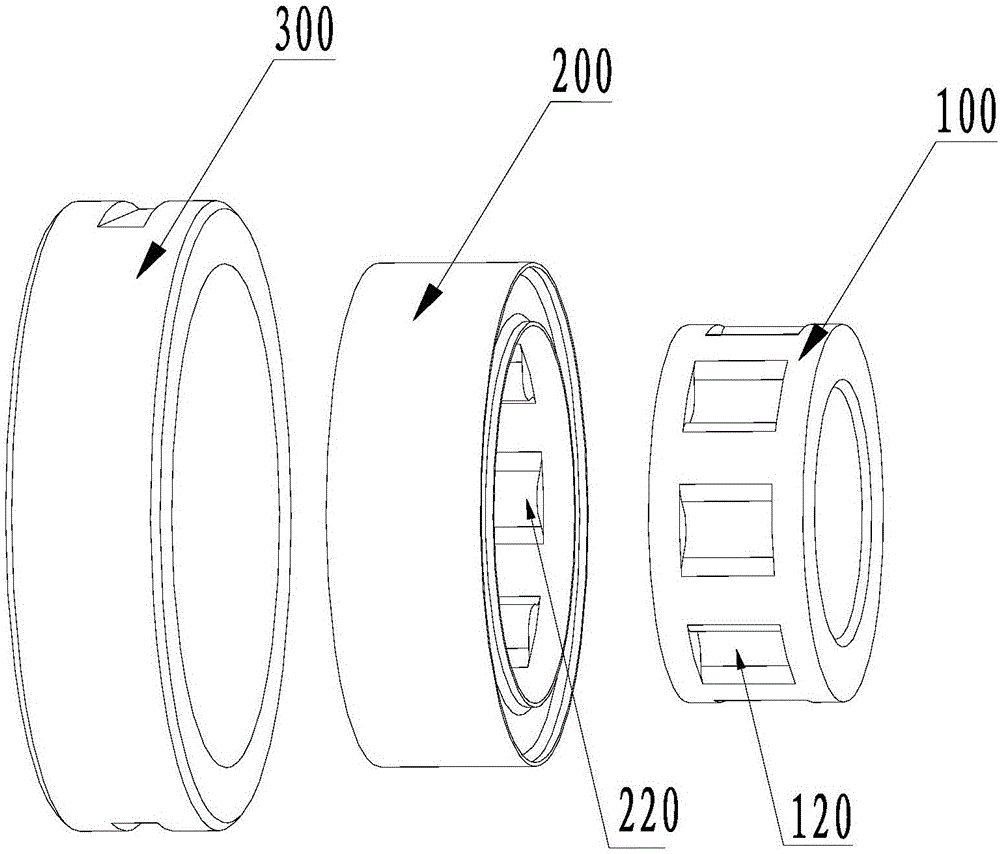

[0058] Such as image 3 with Figure 4 As shown, a plurality of first grooves 120 are uniformly arranged on the outer surface of the inner sleeve 100, and a plurality of second protrusions 220 corresponding to the first grooves 120 are arranged on the inner surface of the middle layer 200, The second protrusion 220 is embedded in the first groove 120 . In this way, the contact area between the inner sleeve 100 and the middle layer 200 is increased, and when the shock absorber is subjected to torque during operation, the possibility of the inner sleeve 100 being separated from the middle layer 200 is reduced, and the shock absorber’s bearing capacity is improved. The ability of the wind blade to rotate at a high speed improves the reliability of the shock absorber.

[0059] Of course, the first groove 120 provided on the outer surface of the inner sleeve 100 can also be an annular groove concentrically arranged on the outer periphery of the inner sleeve 100. At this time, the...

Embodiment 3

[0062] Such as Figure 5 with Image 6 As shown, as a further improvement, a plurality of first protrusions 110 are evenly provided on the outer surface of the inner sleeve 100, and a plurality of first protrusions 110 corresponding to the first protrusions 110 are arranged on the inner surface of the middle layer 200. The second groove 210 , the first protrusion 110 is embedded in the second groove 210 . In this way, the contact area between the inner sleeve 100 and the middle layer 200 is increased, and when the shock absorber is subjected to torque during operation, the possibility of the inner sleeve 100 being separated from the middle layer 200 is reduced, and the shock absorber’s bearing capacity is improved. The ability of the wind blade to rotate at a high speed improves the reliability of the shock absorber.

[0063] Of course, the first protrusion 110 provided on the outer surface of the inner sleeve 100 can also be an annular boss concentrically arranged on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com