A Multifunctional Clutch Test Bench

A clutch and test bench technology, applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems such as the large influence on the machining accuracy of the flywheel, the high risk factor of the test bench operation, and the inability to simulate the road spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

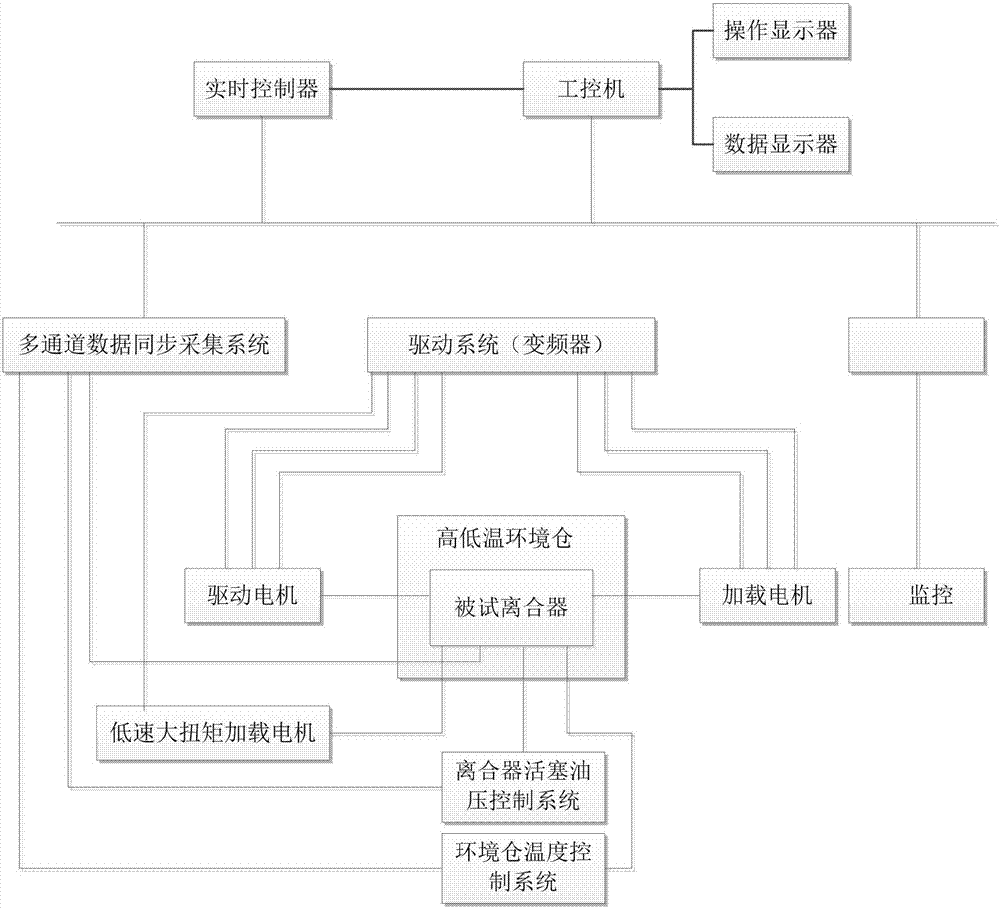

[0037] figure 1 It is a multifunctional clutch test bench (hereinafter referred to as the test bench). The test bench consists of a drive loading system, a clutch piston pressure oil supply adjustment system, a clutch lubricating oil temperature control system, a clutch ambient temperature control system, a real-time control system, a sensor data acquisition system, an auxiliary monitoring system and an upper computer operating system.

[0038] Each subsystem is described below:

[0039] (1) Driver loading system

[0040] The driving and loading system is composed of AC inverter, driving motor, static torsion motor, loading motor, two-speed gearbox, coupling, transmission shaft, motor mounting base, gearbox mounting base, bearing housing and corresponding control electrical circuits. The electric control schematic diagram of the drive and loading system is shown in figure 1 .

[0041] The loading motor is used to simulate the load inertia, and the driving motor is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com