Wireless remote laser gas and dust synchronous online detector

A technology of laser gas and detectors, applied in the direction of color/spectral characteristic measurement, measuring devices, scientific instruments, etc., can solve the problems of adding equipment, long distance between the main control room and field equipment, inconvenient work, etc., and reduce the trouble of wiring , Save equipment cost, save engineering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

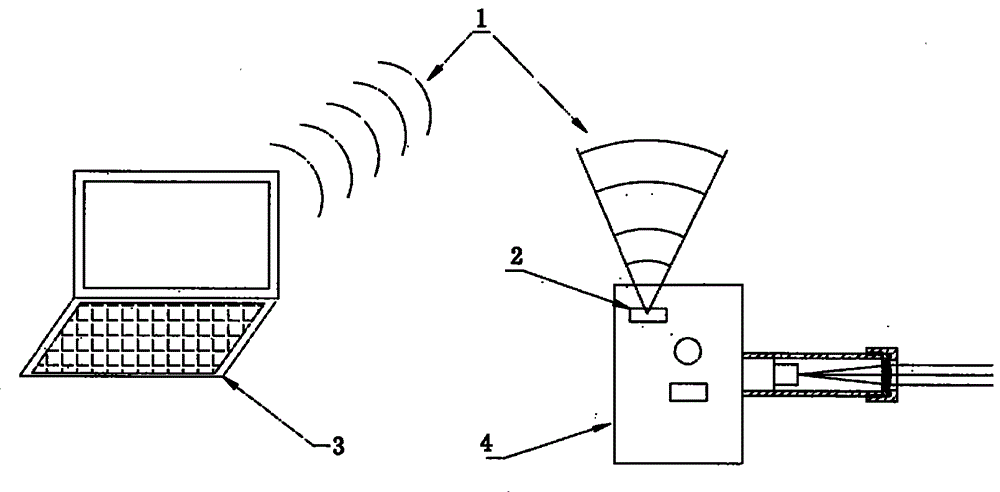

[0017] The wireless remote laser gas and dust synchronous online detector specifically includes a laser emitting unit, a laser receiving unit, a gas absorption signal processing module, a dust light scattering signal processing module, a program control switch module for gas and dust detection, an optical path adjustment and connection device, and a purge Gas system, power supply system, human-computer interaction and external interface system, analyzer chassis, remote device terminal of wireless transceiver, networked main control terminal, directional control software, etc. For the gas to be measured, first find out the specific absorption wavelength of the gas to be measured. The tunable semiconductor laser of the corresponding wavelength is selected according to the specific absorption wavelength of the gas to be measured. By controlling t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap