Hole layer optical proximity correction method for avoiding large aspect ratio pattern

A technology of optical proximity correction and aspect ratio, which is applied in optical, patterned surface photoengraving process, and originals for opto-mechanical processing. , to achieve the effect of minimum edge position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

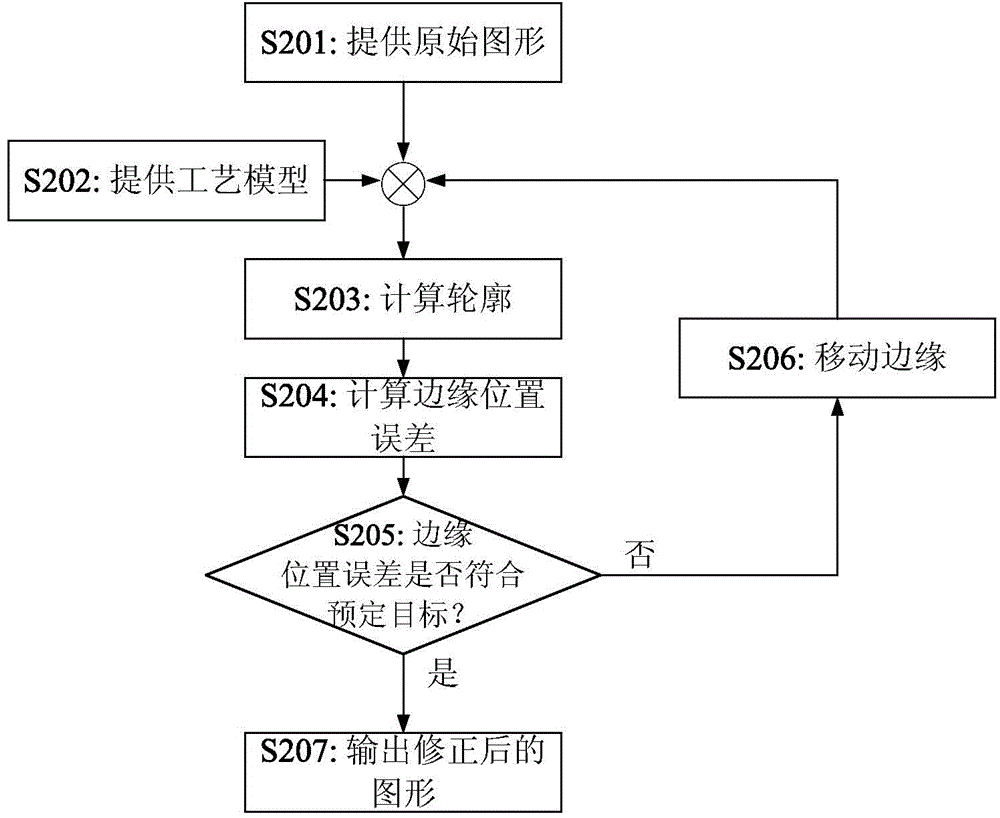

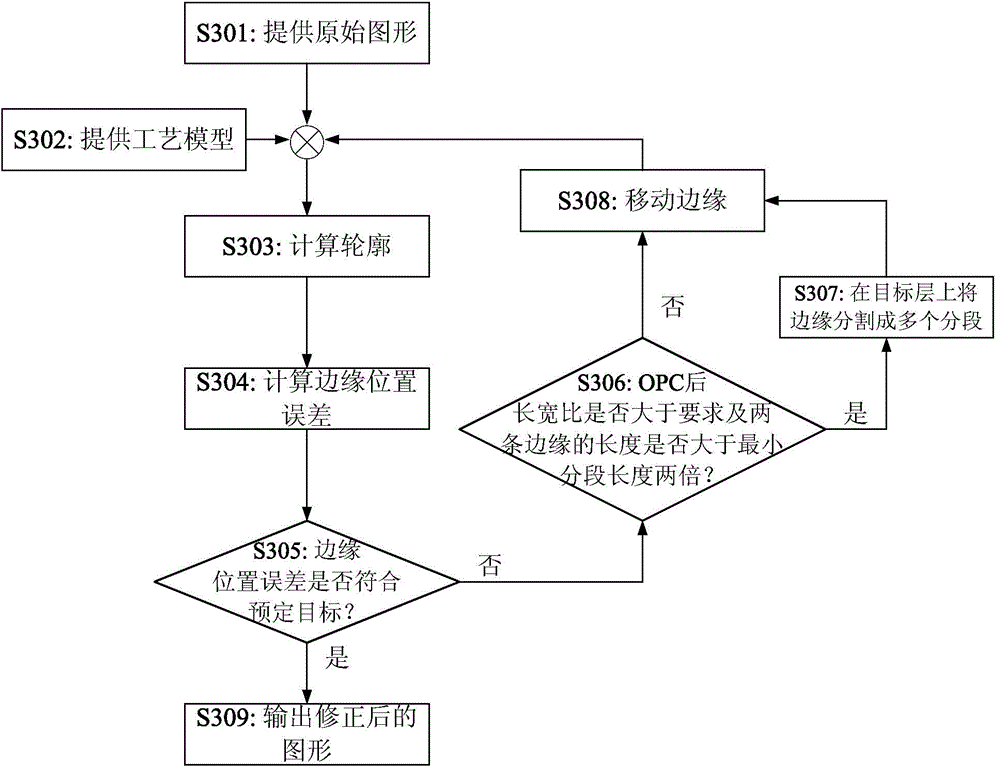

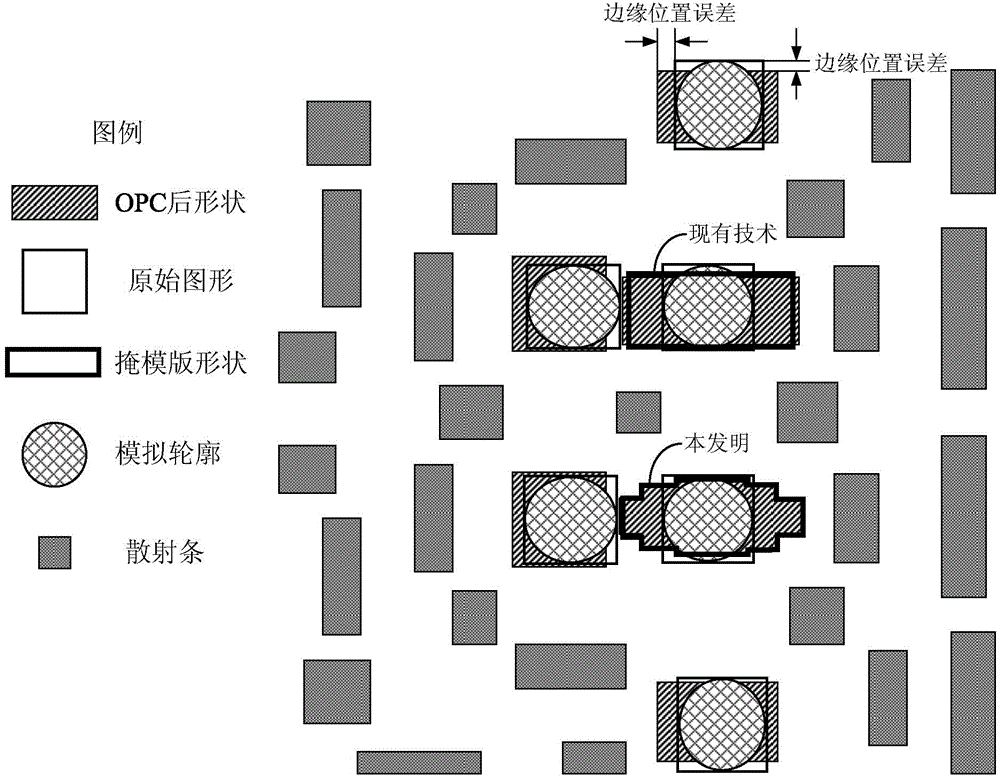

[0038] For comparison, before describing the hole layer optical proximity correction method for avoiding large aspect ratio patterns of the present invention, first describe how the traditional hole layer optical proximity correction method in the prior art is implemented. figure 1 It is a flow chart of a traditional optical proximity correction method for a hole layer in the prior art; image 3 It is a schematic diagram comparing the post-OPC shape and the shape of the reticle obtained by using the traditional hole layer optical proximity correction method and the hole layer optical proximity correction method avoiding large aspect ratio patterns according to an embodiment of the present invention. Such as figure 1 and combine image 3 As shown, the process includes steps:

[0039] Execute step S201 to provide the original graphics to be corrected;

[0040] Execute step S202 to provide an optical proximity correction process model (not shown), which is an OPC algorithm;

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap