Shift register and driving method thereof, grid driving circuit, and display apparatus

A technology of a shift register and a driving method, which is applied in the fields of a shift register and its driving method, a gate drive circuit, and a display device, and can solve problems such as poor anti-noise capability and unreasonable shift register circuit structure, and achieve strong anti-corrosion Effect of Noise Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

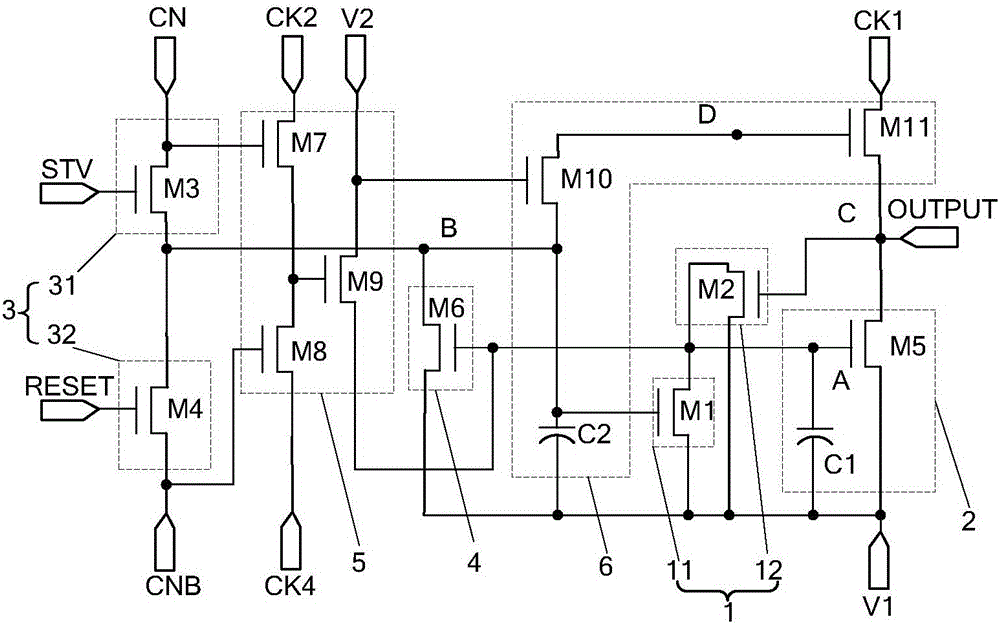

[0026] The inventor of the present application found that: the feedback module in the existing shift register only includes one transistor, therefore, when the transistor fails to work normally, for example, the level of the control point connected to the control terminal of the transistor is unstable, or , when the transistor is damaged, the shift register has no ability to resist noise.

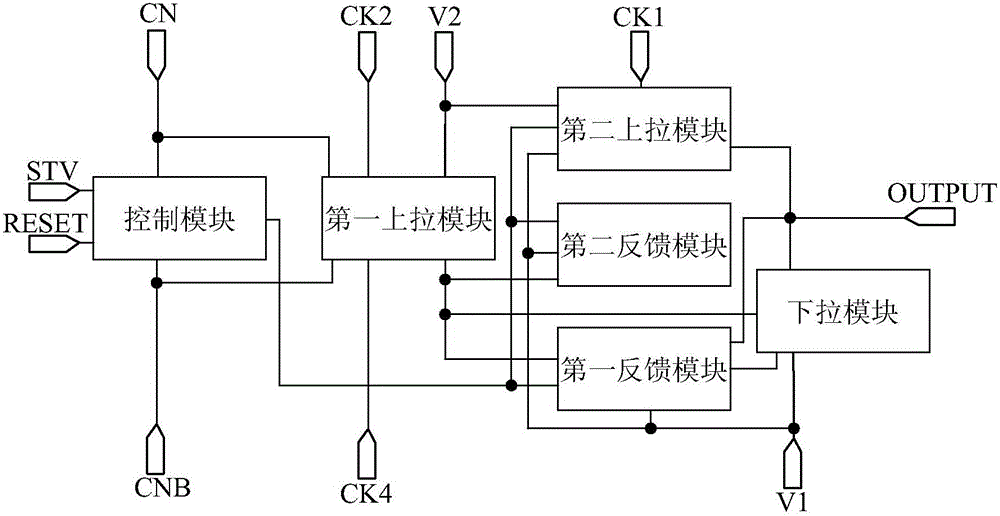

[0027] In view of this, the inventor of the present application provides an improved technical solution, by setting at least two feedback units in the first feedback module, the control terminals of each feedback unit are respectively connected to different control points, and each feedback unit The input terminals of each feedback unit are connected to the first level input terminal, and the output terminals of each feedback unit are connected to the control terminal of the pull-down module, and each feedback unit can independently control the connection between the control terminal of the ...

Embodiment 2

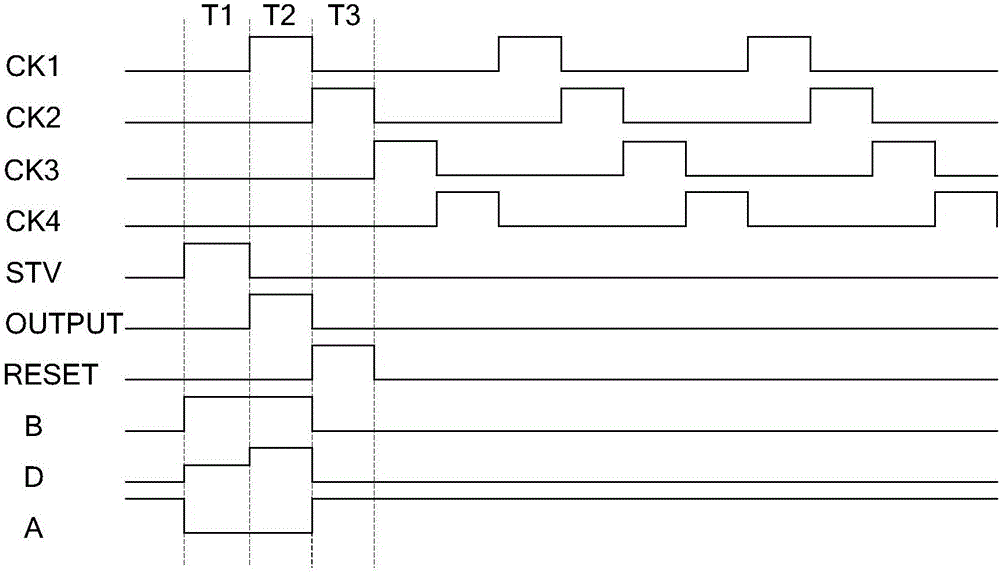

[0046] An embodiment of the present invention provides a driving method of a shift register, the driving method is used to drive the above-mentioned shift register, and the driving method includes:

[0047] Different feedback units included in the first feedback module are controlled through different control points to control the potential of the first node, and the pull-down module is controlled through the first node to control the connection between the first level input terminal and the signal output terminal.

[0048] Since the different feedback units included in the first feedback module are controlled through different control points, and the input end of each feedback unit is connected to the first level input end, and the output end of each feedback unit is connected to the control end of the pull-down module, Each feedback unit can independently control the connection between the control terminal of the pull-down module and the first level input terminal, so even if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com