Ear and Stem Harvesting Header for Corn Harvesting

A technology for harvesting headers and corn, applied to headers, harvesters, agricultural machinery and implements, etc., can solve the problems of low quality of silage or yellow silage, low quality of stalk cutting, low operation efficiency, etc. The effect of low loss, high quality stalk chopping and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

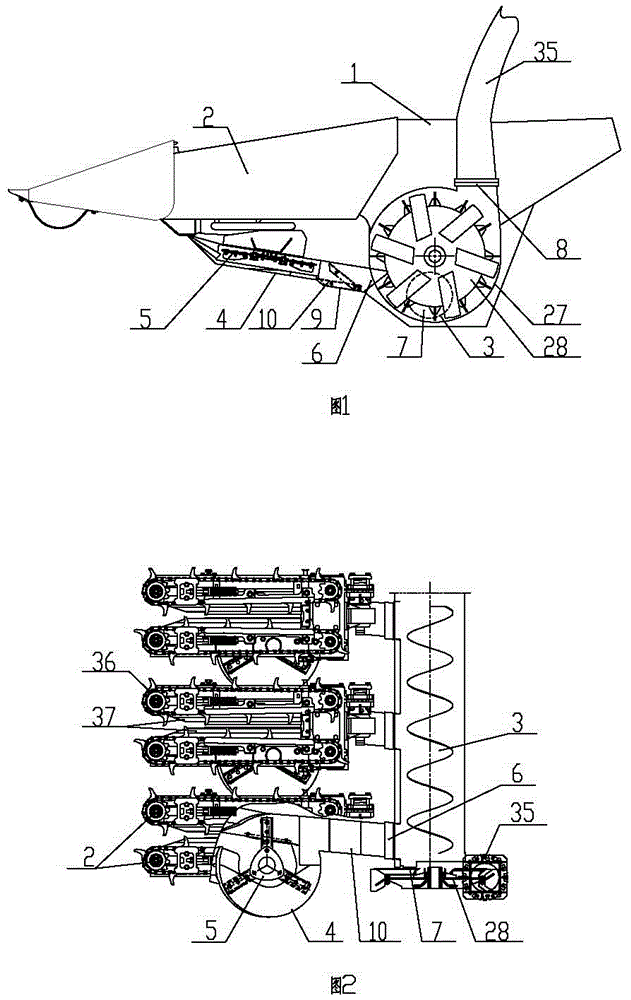

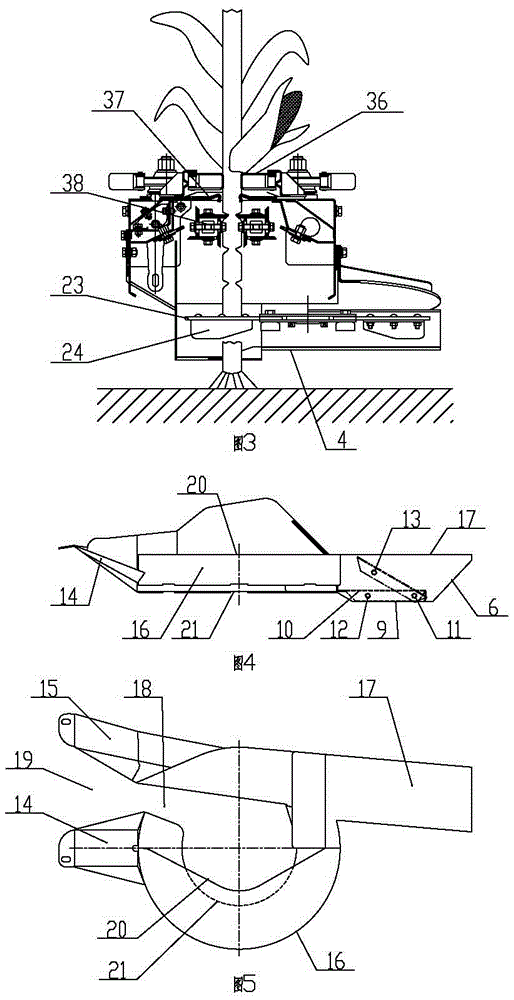

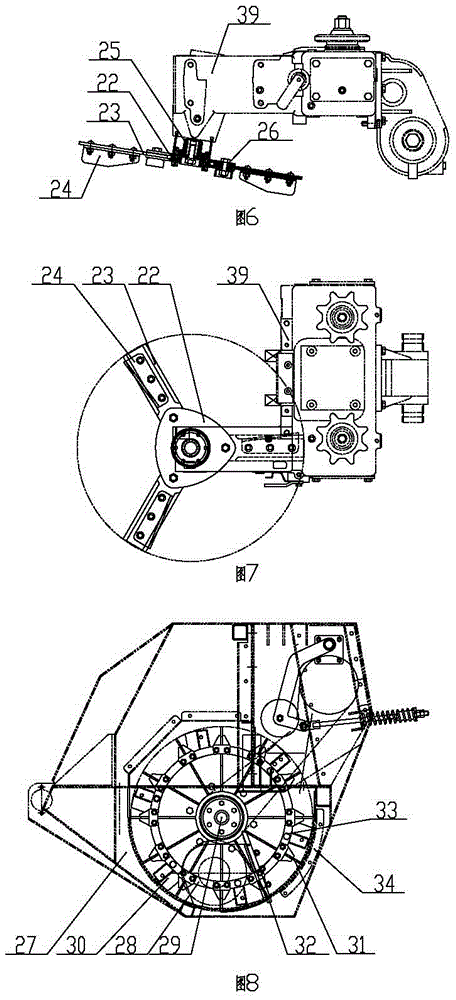

[0034] Embodiment 1: As shown in accompanying drawings 1, 2, and 8, the cutter wheel crushing device is fixedly installed on the left part of the header body 1, and the crushing feed port 7 is located at the lower right end of the crushing shell 27, and the grass collecting conveying device 3 An auger blade capable of pushing materials to the left end of the inner cavity is installed, the feeding port of the grass-collecting conveying device 3 is located at the front end of the grass-collecting conveying device 3, and the outlet of the grass-collecting conveying device 3 is located at the left end of the grass-collecting conveying device 3 And it is fixedly connected with the crushing feed port 7;

[0035] Or, according to actual needs, the cutter wheel crushing device is fixedly installed on the right part of the header body 1, and the crushing feed opening 7 is located at the left end lower part of the crushing housing 27, and a grass harvesting conveyor 3 is installed with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com