Preparation method of polyphenylene sulfide composite filter material filter bag

A composite filter material and polyphenylene sulfide technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of affecting the service life of the filter bag, leaking and accumulating ash in the side seam, limiting the discharge accuracy of the filter bag, etc. , to achieve the effect of improving pinhole ash leakage, good temperature resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0024] The preparation method of a kind of PPS composite filter material filter bag provided by the present embodiment comprises the following steps:

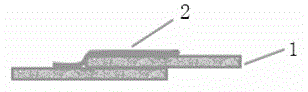

[0025] Step 1. Select polytetrafluoroethylene filter cloth with a weight of 100 per square meter as the base cloth, select 1.0-1.5 decitex ultrafine polyphenylene sulfide fibers to lay the surface layer, and select 1.0 decitex ultrafine polyphenylene sulfide fibers Fiber and common polyphenylene sulfide fiber of 2.0 dtex are mixed to lay the bottom layer; and the mass ratio of superfine polyphenylene sulfide fiber and common polyphenylene sulfide fiber in the bottom layer is 1:2, and then through needle punching or water The spines secure the top layer to the upper surface of the base fabric while securing the bottom layer to the lower surface of the base fabric.

[0026] Step 2: Cut the high-temperature-resistant, acid-alkali-resistant PTFE composite tape into specifications with a width of 2 to 5 cm according to the actual si...

specific Embodiment 2

[0032] The preparation method of a kind of PPS composite filter material filter bag provided by the present embodiment comprises the following steps:

[0033] Step 1: Select the polytetrafluoroethylene filter cloth with a weight of 130 per square meter as the base cloth, select 1.33 decitex ultrafine polyphenylene sulfide fibers to lay the surface layer, select 1.33 decitex ultrafine polyphenylene sulfide fibers and 2.2 decitex ordinary polyphenylene sulfide fibers are mixed to lay the bottom layer; and the mass ratio of ultrafine polyphenylene sulfide fibers and ordinary polyphenylene sulfide fibers in the bottom layer is 3:7, and then the the top layer is secured to the upper surface of the base fabric while securing the bottom layer to the lower surface of the base fabric;

[0034] Step 2: Cut the high-temperature-resistant, acid-alkali-resistant PTFE composite tape into specifications with a width of 2 to 5 cm according to the actual size of the lap seam of the PPS composi...

specific Embodiment 3

[0040] The preparation method of a kind of PPS composite filter material filter bag provided by the present embodiment comprises the following steps:

[0041] Step 1. Select the polytetrafluoroethylene filter cloth with a weight of 200 per square meter as the base cloth, select 1.5 decitex ultrafine polyphenylene sulfide fibers to lay the surface layer, select 1.5 decitex ultrafine polyphenylene sulfide fibers and 2.5 decitex ordinary polyphenylene sulfide fibers are mixed to lay the bottom layer; and the mass ratio of ultrafine polyphenylene sulfide fibers and ordinary polyphenylene sulfide fibers in the bottom layer is 1:3, and then the The top layer is secured to the upper surface of the base fabric while the bottom layer is secured to the lower surface of the base fabric.

[0042]Step 2: Cut the high-temperature-resistant, acid-alkali-resistant PTFE composite tape into specifications with a width of 2 to 5 cm according to the actual size of the lap seam of the PPS composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap