Plate fixing device used for welding and having adjustable locking and unlocking speeds

A technology for fixing devices and panels, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve problems such as difficult positioning and locking effects, and difficult and fast execution of loosening and transporting procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

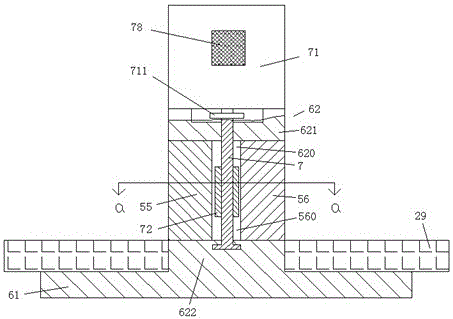

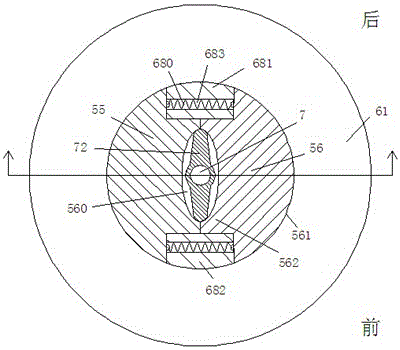

[0009] Combine below Figure 1-2 The present invention will be described in detail.

[0010] A welding panel fixing device with adjustable locking and unlocking speed according to an embodiment, comprising a carrying chassis 61 for carrying the plate 29 to be welded and fixedly connected to the carrying chassis 61 and vertically An extended fixed cylindrical part 62, the fixed cylindrical part 62 includes two fixed columns 681, 682 extending vertically and diametrically opposite, and a top wall fixedly connected to the upper ends of the two fixed columns 681, 682 part 621 and the column root part 622 fixedly connected with the lower ends of the two fixed columns 681, 682, and the telescopic channel 620 extending in the horizontal direction between the two fixed columns 681, 682 is slidably provided with Two locking sliders 55, 56 symmetrical to the central axis of the solid cylindrical part 62, the two locking sliders 55, 56 each have an outer peripheral portion 561 and an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com