A method for improving the glossiness of pipes

A gloss and pipe technology, applied in the field of pipe processing, can solve the problems of low finish and large pipe roughness, and achieve the effect of low friction coefficient, avoiding low production efficiency and low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1. Wipe the opposite surfaces of the core die with a cleaning agent. The cleaning agent is metal cleaner with the product number Q / YS.904 (Yishun brand) produced by Guangzhou Yishun Chemical Co., Ltd.

[0028] Step 2. Heat the solution to 50°C, soak a pure cotton cloth with a thickness of 0.5cm into the solution, and cover the pure cotton cloth on the opposite surface of the core die, and put it at a temperature of 35°C. Remove the pure cotton cloth after 40 minutes.

[0029] Step 3. Use a brush to evenly coat this solution on the opposite surface of the core die in step 2, and place the core die in an oven for baking. Bake for 10 minutes.

[0030] Step 4. Repeat steps 2 and 3 three times to obtain a core die that can improve the surface finish of the pipe.

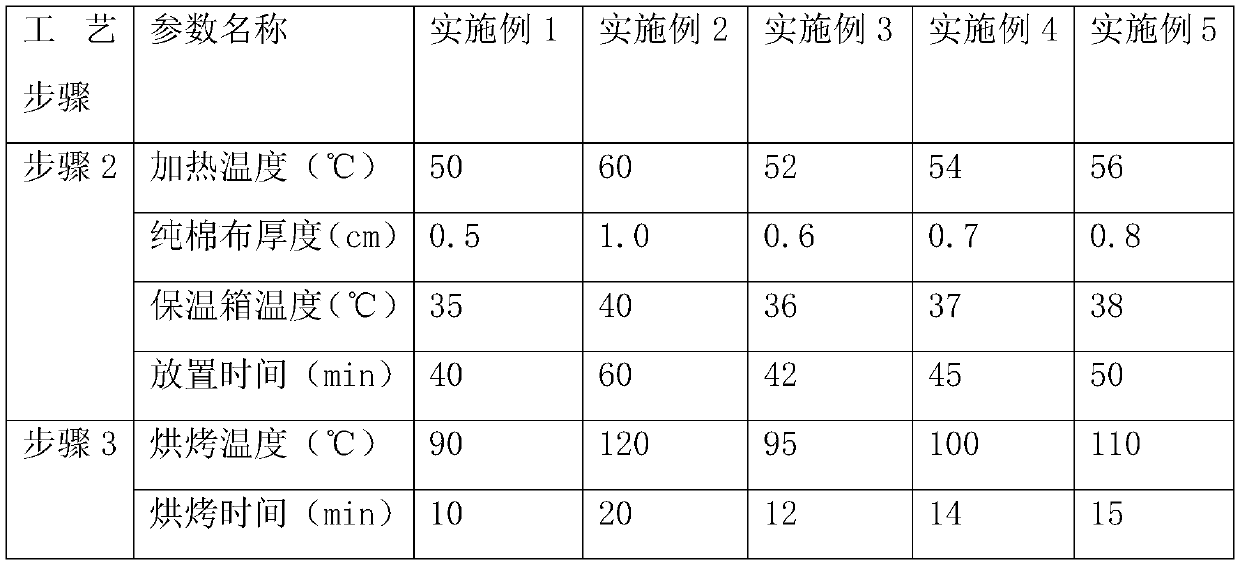

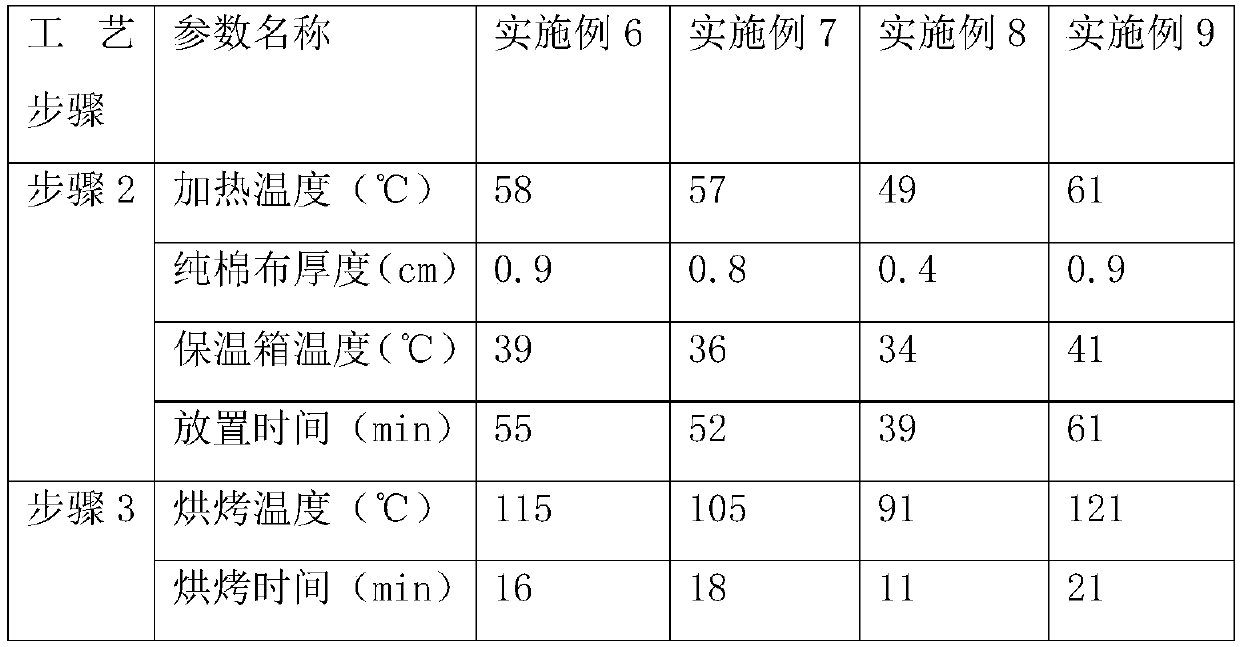

[0031] The coating method in any one of embodiment 2-embodiment 9 is the same as embodiment 1 except that the parameters in table 1 and table 2 are different.

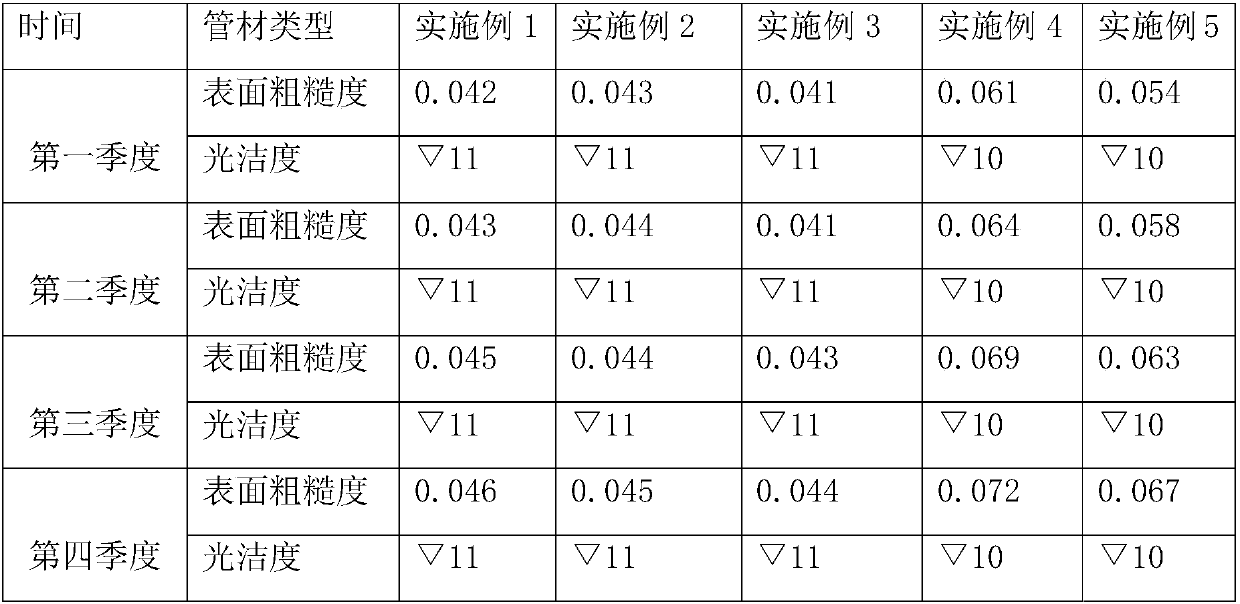

[0032] 3. Test results:

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com