3D (three-dimensional) printing ink box

A technology of 3D printing and ink cartridges, which is applied in the field of 3D printing, can solve the problems of large quantity of stocking, restrictions on the color types of printing consumables and product designs, etc., and achieve the effect of reducing the stocking amount, improving the colorfulness of colors, and improving the visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0023] Another embodiment of the present invention is:

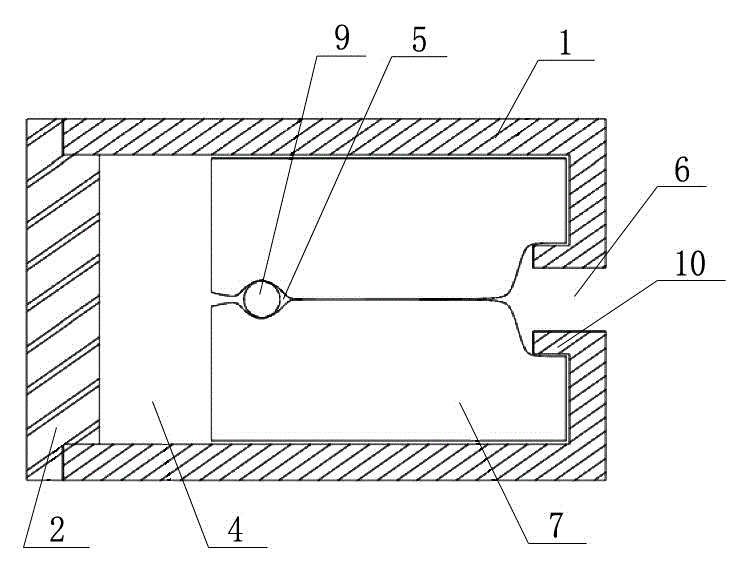

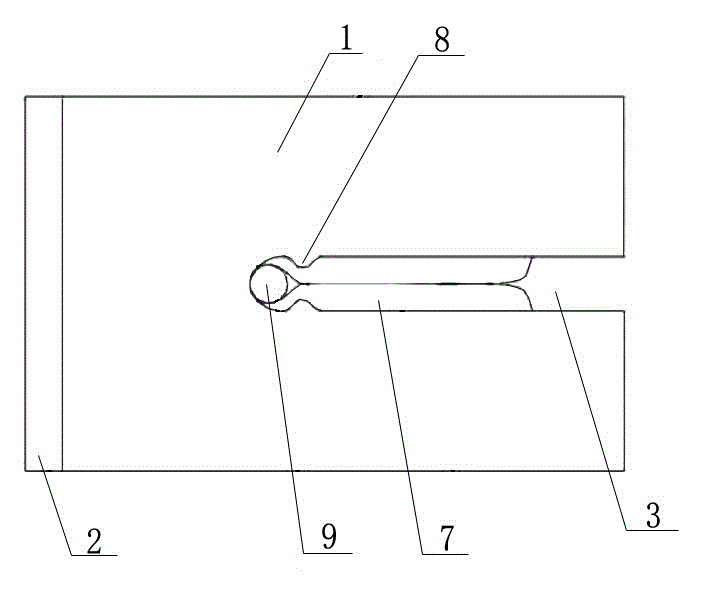

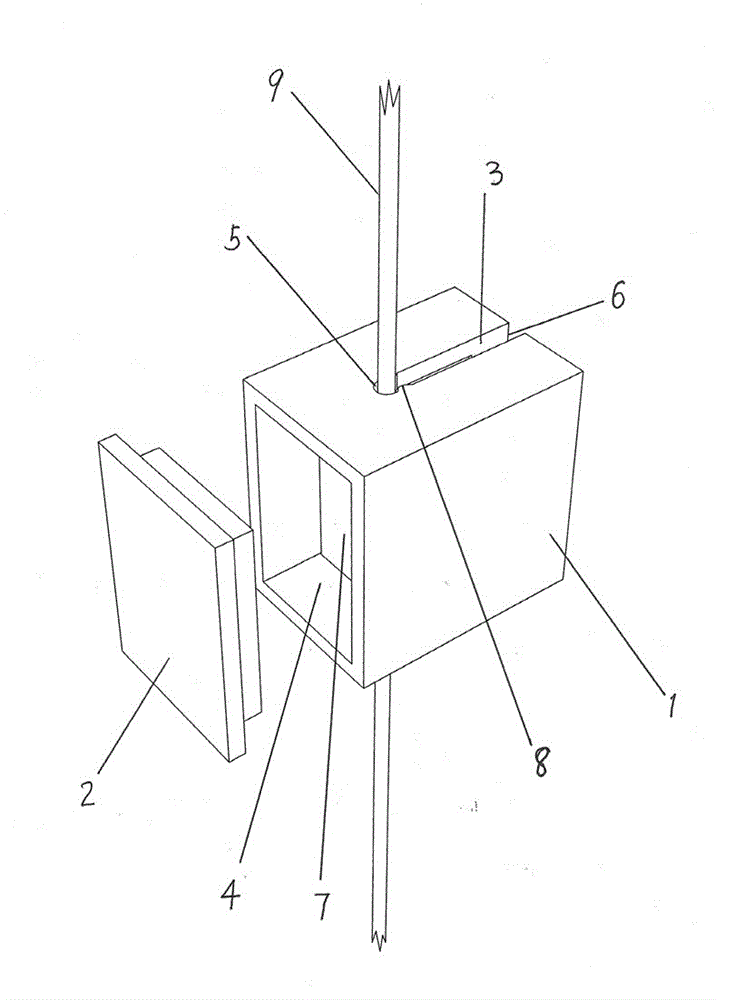

[0024] figure 1 , figure 2 , image 3 As shown, the basic structure of the 3D printing ink cartridge is still the ink cartridge main body 1 and the side cover 2, the cavity of the ink cartridge main body is used to accommodate the dye powder and the sponge, and there are wire holes 5 at the corresponding positions of the top plate and the bottom plate of the ink cartridge main body . The difference is that: the top plate and the bottom plate of the main body of the ink cartridge are symmetrically provided with a wire sliding hole 3; the side plate opposite to the side cover 2 is provided with a wire sliding hole 6 connected to the wire sliding hole. . The wire sliding strip holes of the top plate and the bottom plate are provided with closed ends, and the wire holes 5 are provided at the closed ends. At the same time, a limiting neck 8 is provided at the intersection of the wire hole 5 and the wire sliding bar hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com