A mold template marking machine

A marking machine and template technology, used in typewriters, decorative arts, printing, etc., can solve the problems affecting the sales and quality of molds, hidden dangers, and high costs, and achieve the effects of improving labor production efficiency, convenient disassembly and maintenance, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

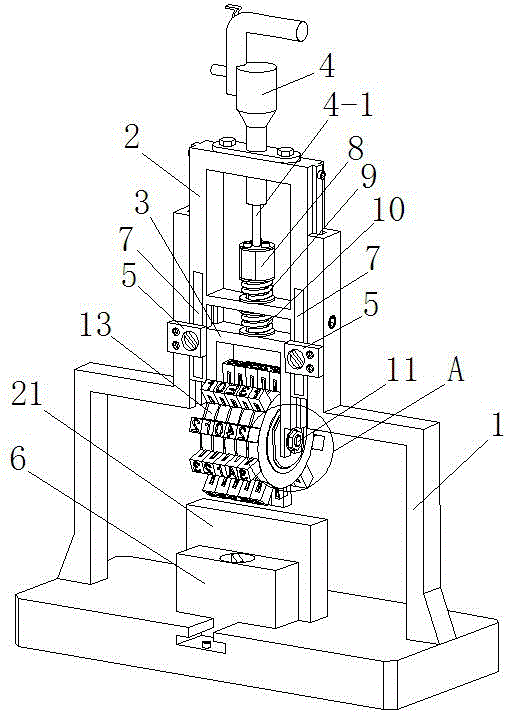

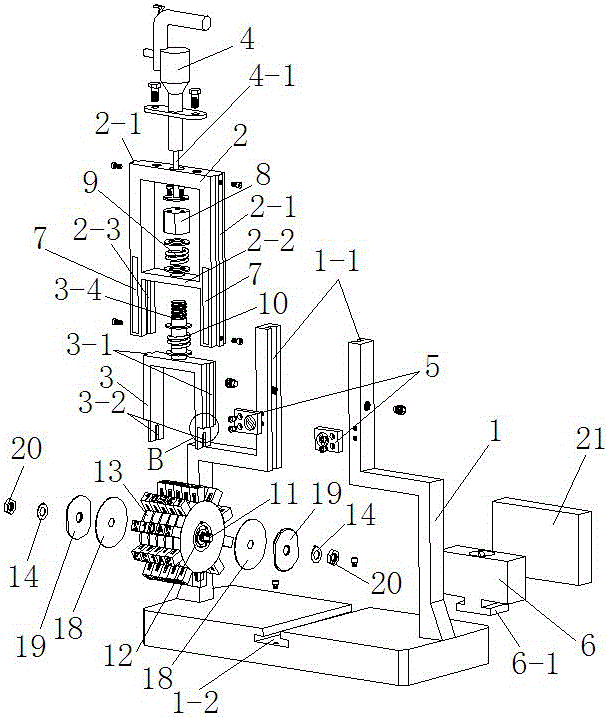

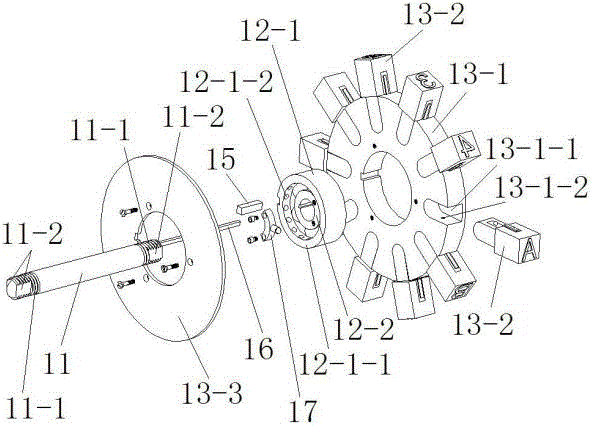

[0021] Example: see attached figure 1 ~ attached Figure 8 , a mold template marking machine, comprising a convex-shaped base 1 with an open top, a rectangular lifting frame 2 with an open bottom, a rectangular vibration bracket 3 with an open bottom, and an air hammer 4 fixed on the upper end of the lifting frame 2 , two electromagnetic locking suction cups 5 respectively fixed on the two side walls of the upper end of the base 1, an electromagnetic fixed suction cup 6 fixed on the base 1, and an engraving turntable assembly.

[0022]Vertical long grooves 1-1 are respectively provided on both sides of the upper end of the base 1. The notches of the two long grooves 1-1 are opposite to each other. The two side arms of the lifting frame 2 are respectively provided with vertical ribs 2-1. The two protruding ribs 2-1 of the lifting frame 2 are slidingly matched with the two long grooves 1-1 of the base 1 respectively, a horizontal beam 2-2 is arranged in the middle of the liftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com