A tire changer assistant

A tire changer and assistant technology, applied in tire installation, tire parts, transportation and packaging, etc., can solve problems such as poor side guidance, single type, slow unlocking, etc., to improve assembly, long service life, and durability. The effect of force equalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be further described below in conjunction with the drawings.

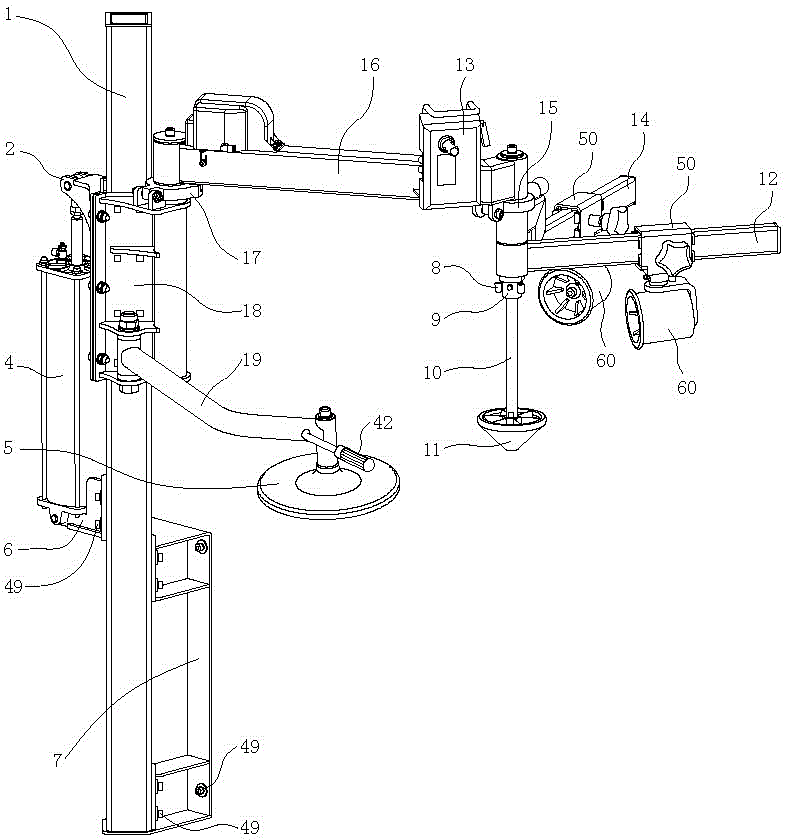

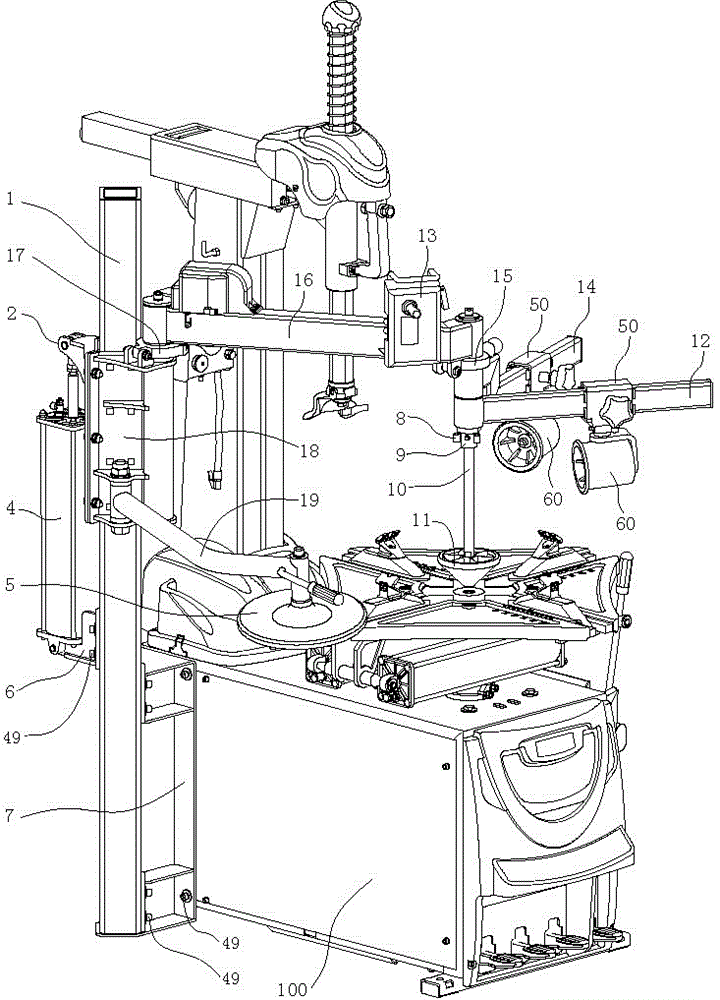

[0087] figure 1 Shown is an example of a preferred solution of the present invention, figure 2 It is shown that the assistant of the embodiment of the present invention is connected to the main body 100 of the disassembler, which is a push-pull arm type tire changer with a tiltable column.

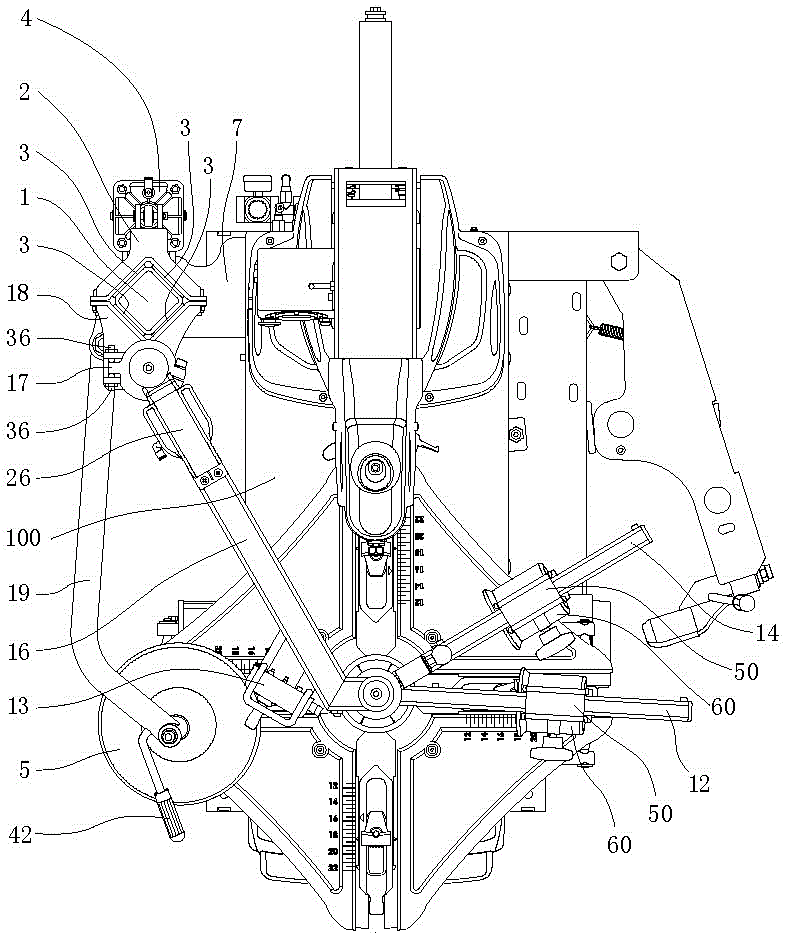

[0088] Such as figure 2 , Figure 4 As shown, the square rail 1 is set on the assistant bracket 7 and is connected and fixed with fasteners 49. The assistant bracket 7 is set on the operating side of the main body of the disassembly and assembly machine 100 and is connected and fixed with fasteners 49. There is a The sliding body sliding along the square rail 1, such as Figure 7 , Picture 8 , Picture 11 As shown, the sliding body includes a front half body 18, an anti-friction sheet 3, and a rear half body 2, which are connected by a screw 46, a washer 47, and a lock nut 48, which are combined a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com