Lotion pump and lotion bottle

A technology of lotion pump and lotion bottle, applied in the field of lotion pump and lotion bottle, can solve the problems of increased components, prone to sticking, rising production cost, etc., so as to avoid processing cost, avoid smooth movement of lotion pump and sticking phenomenon , the effect of increasing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

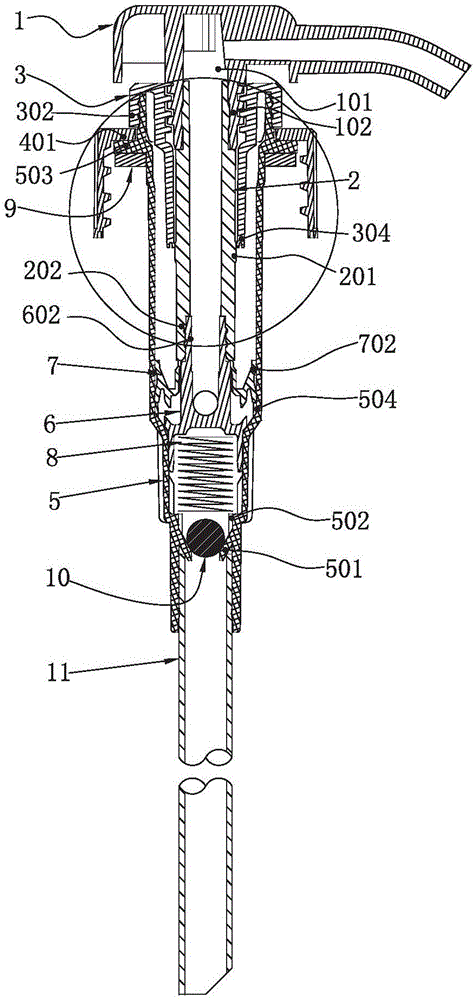

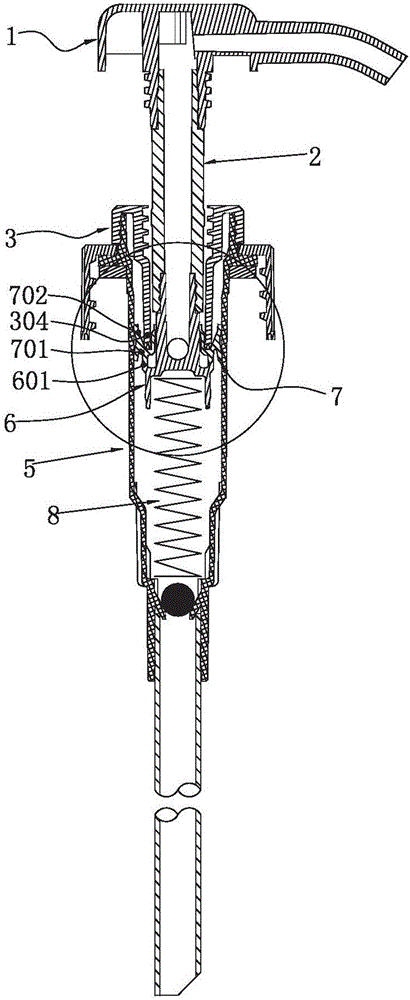

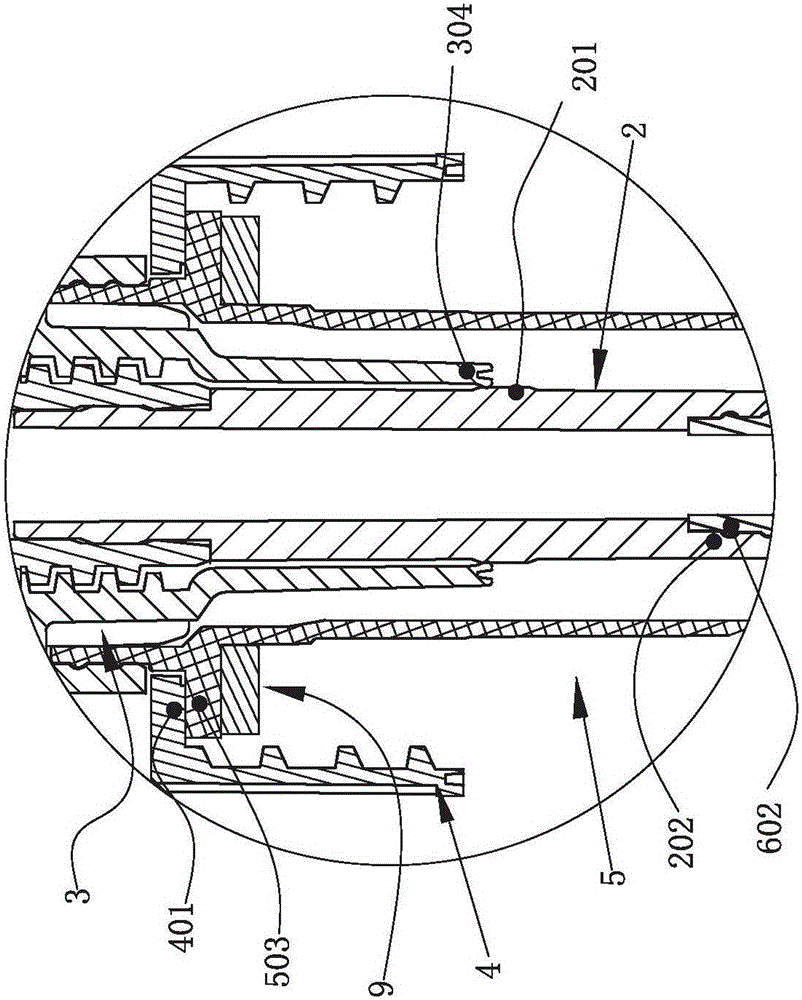

[0028] The lotion bottle provided by the invention is composed of a lotion pump and a bottle body. The lotion bottle has a bottle body, and the lotion pump is installed on the bottle body. Since the present invention mainly improves the lotion pump, the lotion pump will be described in detail below. Such as figure 1 , figure 2 As shown, the lotion pump of the present invention is a leak-proof lotion pump on the surface of a sealed main column, which includes a press head 1, a main column 2, a lock cover 3, a screw sleeve 4, a body 5, an auxiliary column 6, a piston 7, and a spring 8 , gasket 9, glass ball 10 and straw 11.

[0029] The upper end of the body 5 is fixedly connected to the outer ring of the lock cover 3 through the screw sleeve 4 , the lower end surface of the sleeve 401 of the screw sleeve 4 is in contact with the shoulder 503 of the body 5 , and the upper end surface of the sleeve 401 is in contact with the outer ring of the lock cover 3 . The lower end surf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap