Methods And Systems For Operating Gas Turbine Engines

A technology for gas turbines and engines, which is used in gas turbine installations, turbine/propulsion fuel delivery systems, engine components, etc., and can solve problems such as complex and expensive manufacturing of purge systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

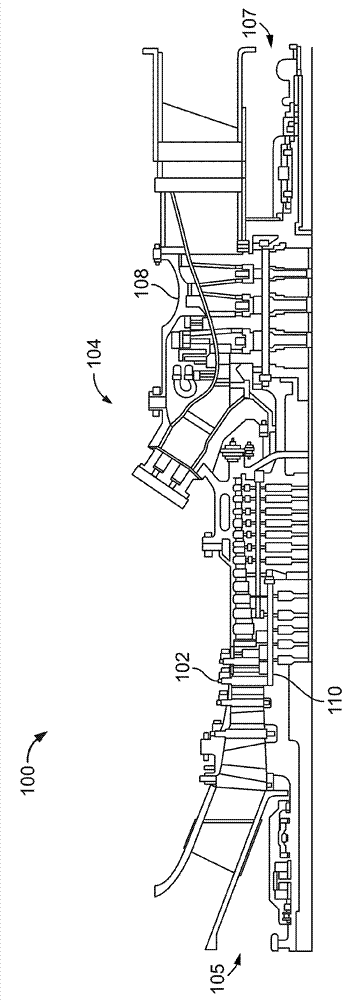

[0070] figure 1 is a schematic diagram of an exemplary gas turbine engine 100 . Engine 100 includes a compressor assembly 102 and a plurality of combustor assemblies 104 . Engine 100 also includes turbine 108 and a common compressor / turbine shaft 110 , sometimes referred to as rotor 110 . Combustor assembly 104 is coupled in flow communication with turbine assembly 108 and with compressor assembly 102 .

[0071] In operation, air enters engine 100 through inlet 105 and flows downstream through compressor assembly 102 such that compressed air is supplied to combustor assembly 104 . The fuel is directed to a combustion zone defined within the combustor assembly 104 ( figure 1 not shown), where fuel is mixed with air and ignited. Combustion gases are generated and channeled to turbine 108 , where thermal energy of the gas flow is converted to mechanical rotational energy and exits engine 100 through outlet 107 . Turbine 108 is rotatably coupled to shaft 110 . As used herein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com