Folding belt transport device of self-unloading sand transport ship

A technology for belt transportation and sand transportation, which is used in transportation and packaging, conveyors, loading/unloading, etc., and can solve the problems of affecting transportation efficiency, occupying a large space, and taking a long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

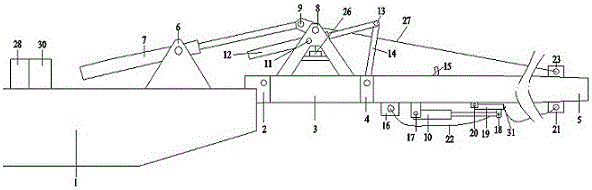

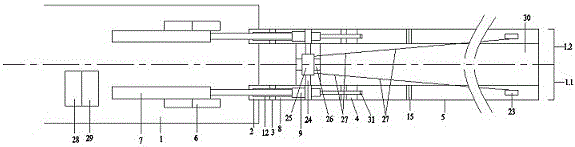

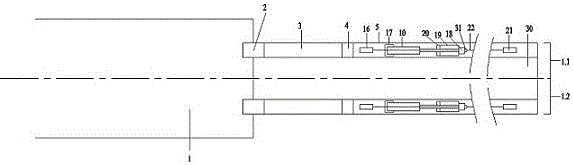

[0015] exist figure 1 , figure 2 with image 3 Among them, the foldable belt transport device of this self-unloading sand carrier includes a bow 1, which is characterized in that the bow 1 is equipped with a first belt mounting frame 3 through a first fixed hinge 2; the right side of the first belt mounting frame 3 The second belt mounting frame 5 is installed by the first living hinge 4; the horizontal center line of the width of the bow 1 is used as a vertical plane to divide the bow 1 into the front part 1.1 of the bow and the rear part 1.2 of the bow; the front part of the bow 1.1 The first fixed hinge support 6 is installed on it; the first fixed hinge support 6 is equipped with the first single-column piston hydraulic cylinder 7; the connection point between the first fixed hinge support 6 and the first single-column piston hydraulic cylinder 7 is located at The right half of the first single-column piston hydraulic cylinder 7 cylinder blocks; the front part of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com