Sewing material conveying apparatus

A conveying device and sewing material technology, which is applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve the problem of not being able to directly grab cloth software materials, etc., and achieve the effect of simple structure, accurate and stable clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

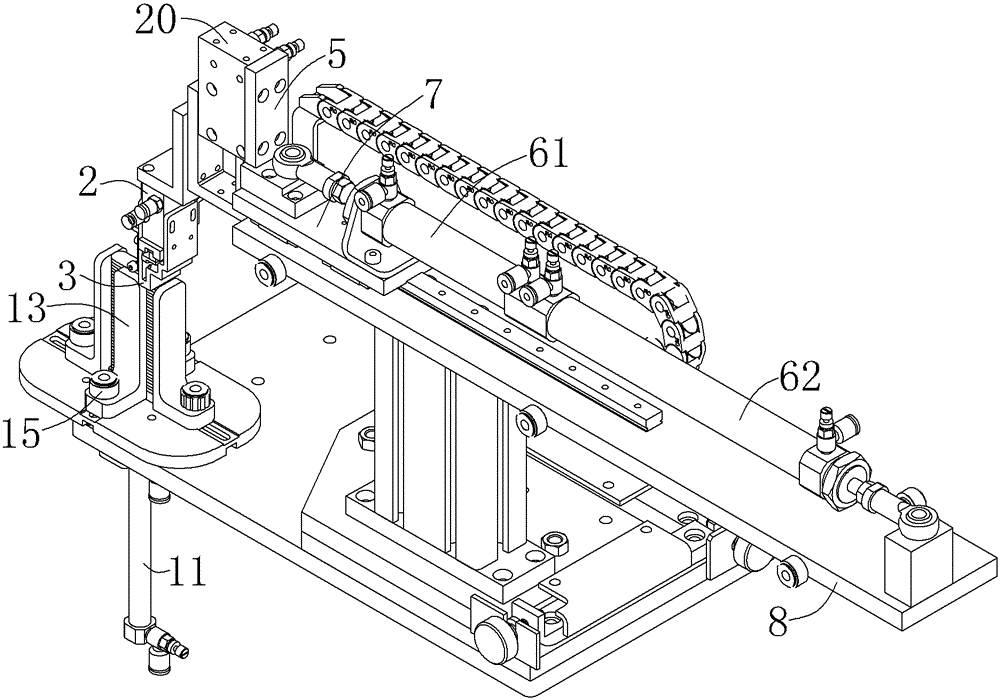

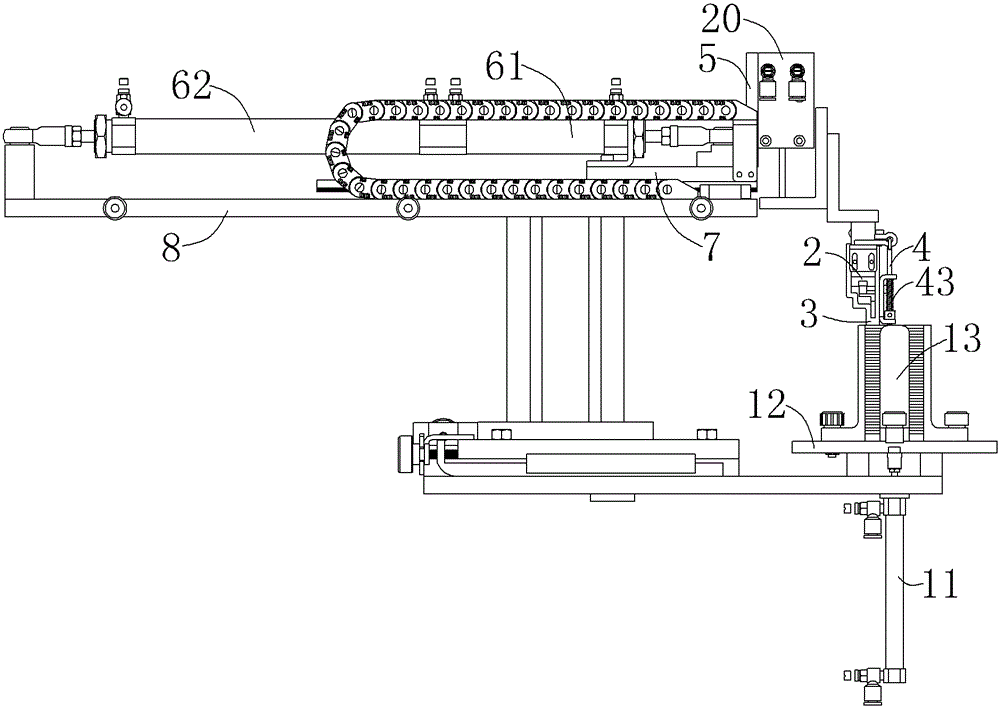

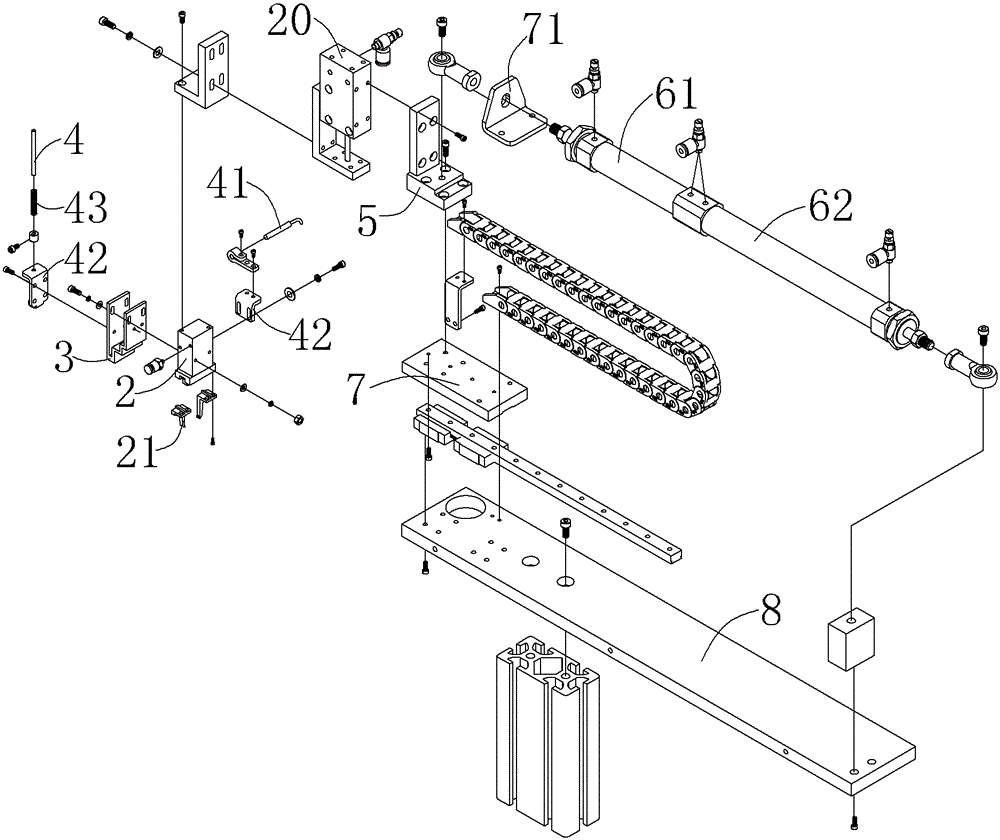

[0022] Figure 1 to Figure 4 Shown is the structural representation of the present invention.

[0023] The reference signs in the figure are: lifting platform 1, lifting cylinder 11, mounting platen 12, side wall bracket 13, chute 14, bolt 15, pneumatic clamping finger cylinder 2, pressing material cylinder 20, pneumatic finger 21, pressing Material frame 3, induction rod 4, sensor 41, induction mounting seat 42, return spring 43, mounting seat 5, first feeding cylinder 61, second feeding cylinder 62, feeding seat 7, cylinder body mounting seat 71, base 8.

[0024] A sewing material conveying device of the present invention has a silo for placing laminated sewing materials, a lifting platform 1 capable of pushing the laminated sewing materials upward, and a lifting cylinder 11 for driving the lifting platform 1 to move up and down.

[0025] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com