Scroll plate component and scroll compressor comprising same

A scroll compressor and scroll disk technology, applied in the field of compressors, can solve problems such as vibration and noise, force imbalance, and high gas velocity in the exhaust hole, and achieve the effect of reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

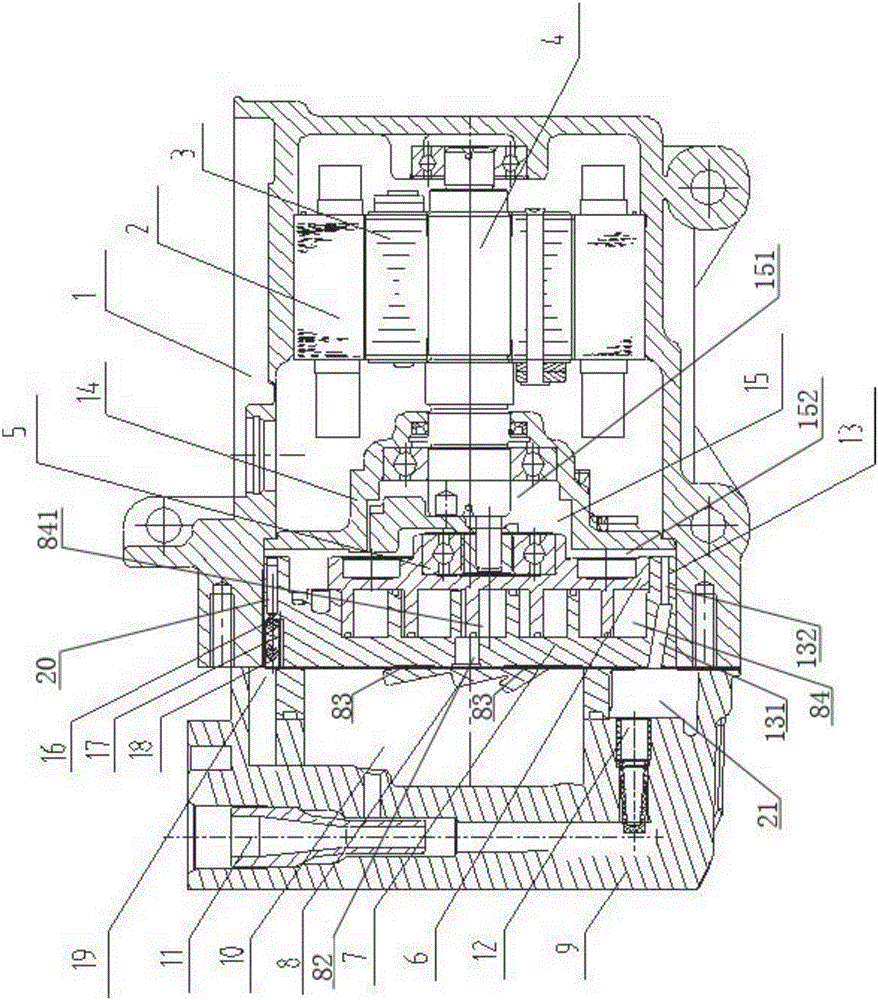

[0043] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

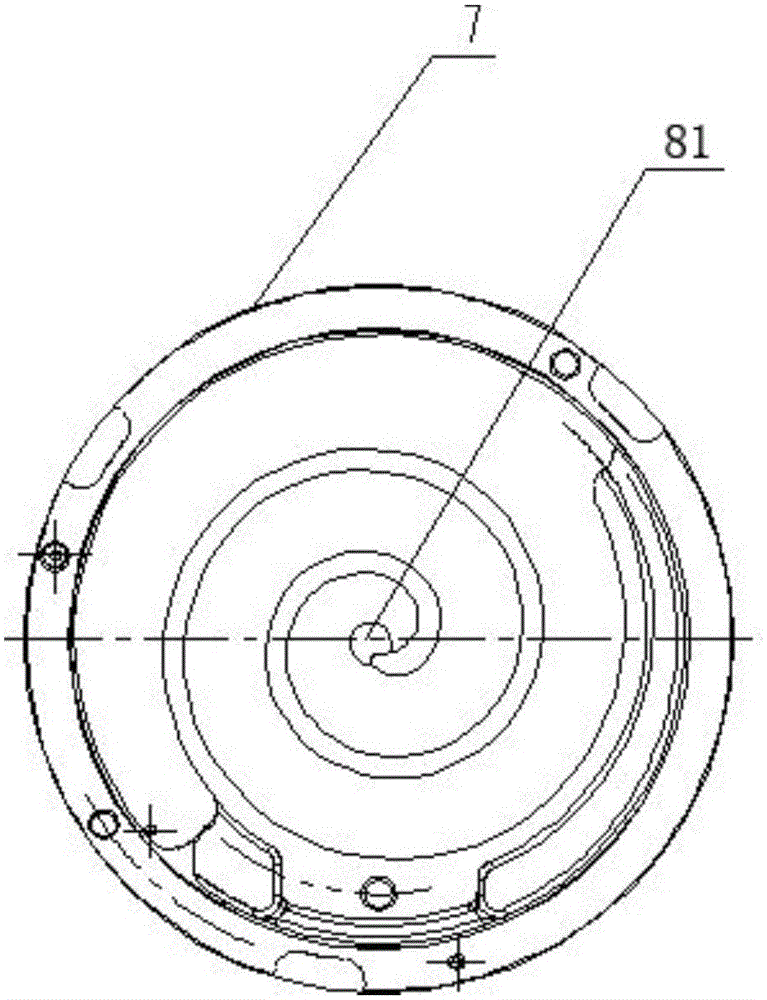

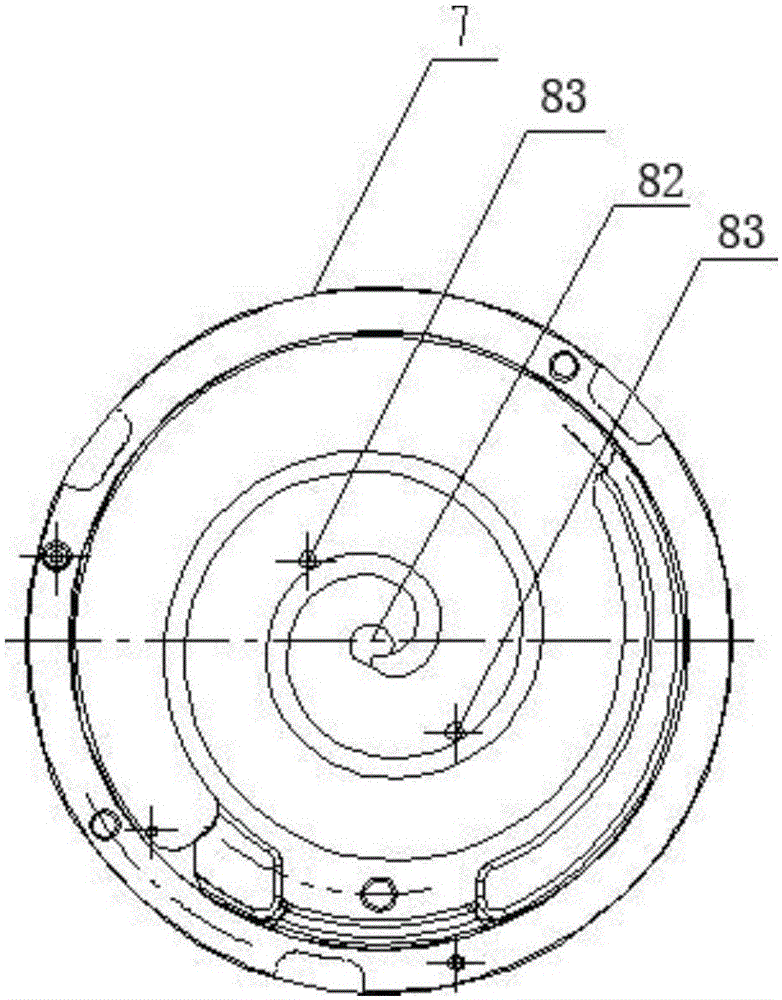

[0044] In order to achieve the purpose of the present invention, as Figure 2-3 As shown, in some embodiments of the scroll assembly of the present invention, it includes the movable scroll 6, the fixed scroll 7 and the first exhaust hole 82 opened at the center of the fixed scroll 6, the first exhaust An exhaust valve plate 8 is arranged on the hole 82, and two second exhaust holes 83 are opened on the static scroll 7, which are arranged symmetrically with respect to the first exhaust hole 82, and the two end compression chambers should be connected with the two exhaust holes at the same time. The two second exhaust holes 82 are connected, which can ensure the symmetry of the suction, compression and exhaust processes of the working chambers on both sides, and avoid additional unbalanced force and vibration; one or more meshes of the movable...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap