Buckle insertion connector and application thereof

A technology for connecting parts and plug-ins, which is applied in the direction of connecting members, thin plate connections, bolts, etc., can solve the problems of inconvenient disassembly and assembly, troublesome installation procedures, non-removable separation, etc., and achieves easy installation and disassembly, convenient subsequent disassembly, and moderate buckle force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

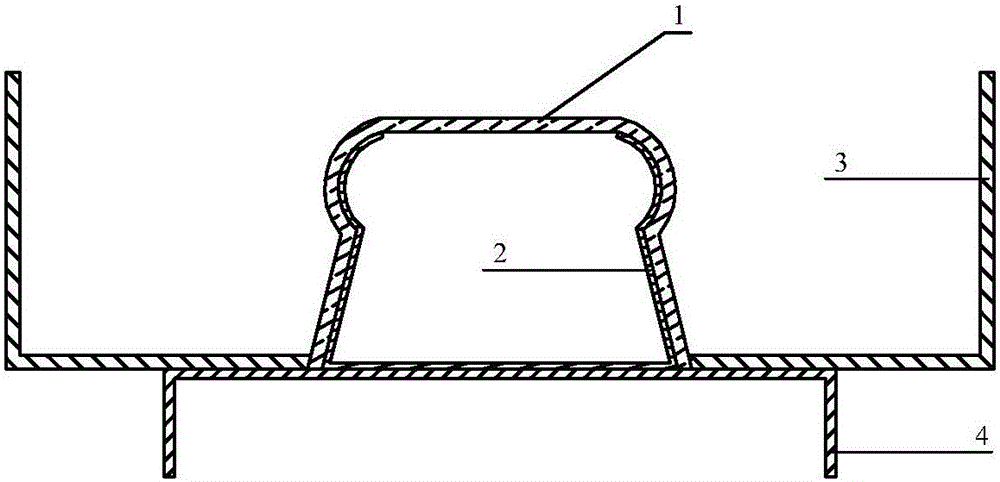

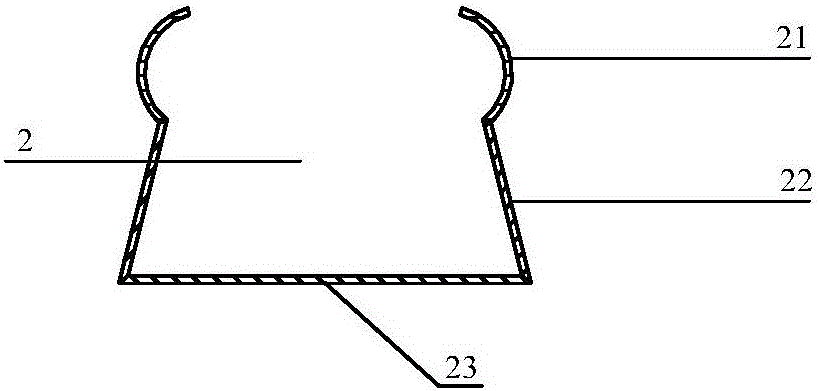

[0032] A buckle-socket connector, including a female connection base 3 and a male connection base 4, the female connection base 3 or the male connection base 4 can be any plate or profile, and the female connection base 3 can be detachable A concave fastener 1 is connected, and a male insert 2 is detachably connected to the convex connection base 4, and the convex insert 2 is plugged into the concave fastener 1. Through this connection method, two base plates or profiles are realized. An effective snap-mating connection, such as figure 1 shown.

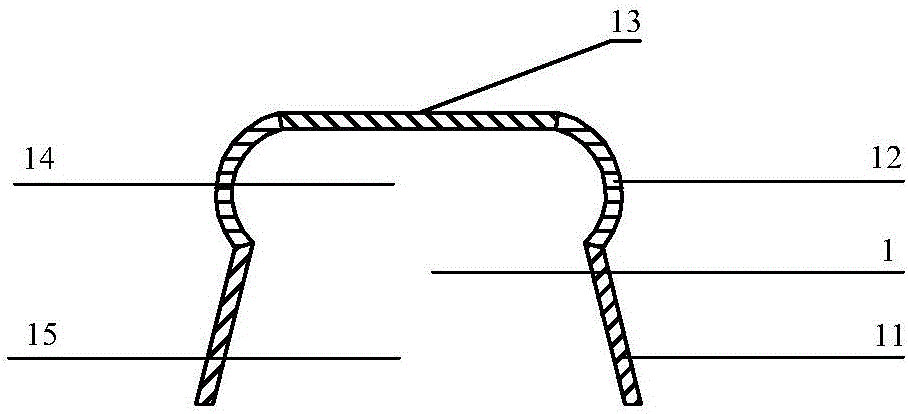

[0033] The concave fastener comprises a concave top connecting piece 13, and a circular arc sleeve 12 is respectively connected to two ends of the concave top connecting piece, and the inner concave surfaces of the two circular arc sleeves are opposite, such as figure 2 As shown, the cavity formed by the two inner concave surfaces and the concave top connecting piece 13 is a concave cavity 14, and the lower ends of the two arc sleev...

Embodiment 2

[0041] This embodiment is identical with embodiment 1 basic structure, and different content or technical parameter are as follows:

[0042] (1), the radius and arc of the arc sleeve and the arc lug are the same, and the arc is 40°.

[0043] (2), the insert piece is made of plastic, and the included angle between the insert piece and the convex bottom connecting piece is 50°.

[0044] (3), the application of the buckle connector, such as Figure 5 As shown, the buckle plug-in connector is applied to the right-angle plug-in connection of the cover edge: the end connecting plate 5 and the side connecting plate 6 are plugged into the buckle plugging inside the concave fastener 1 through the male plug-in 2 The connectors are connected together to form a right-angle plug-in connection mode of the cover, wherein the male plug-in 2 is plugged into the concave fastener 1, the connecting end of the convex plug-in 2 is connected to the plate 5, and the female fastener 1 is connected to...

Embodiment 3

[0046] This embodiment is identical with embodiment 1 basic structure, and different content or technical parameter are as follows:

[0047](1), the radius and arc of the arc sleeve and the arc lug are the same, and the arc is 75°.

[0048] (2), the insert piece is made of metal material, and the included angle between the insert piece and the convex bottom connecting piece is 80°.

[0049] (3) The application of the buckle connector, such as Figure 6 The buckle connector shown in the figure is applied to the edge-to-edge corner plug-in connection: the two end connecting plates 5 are plugged into the concave fastener 1 through the male connector 2, and the buckle connectors inside the female fastener 1 are respectively connected to the corner connecting plates 7, any angle can be formed between the two end connecting plates to form a connection mode of edge-to-edge corner insertion. In this connection, the male insert 2 is plugged into the concave fastener 1, and the male in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com