Changeable stepped damping thrust bearing

A thrust bearing and stepped technology, applied in the field of variable stepped damping thrust bearings, can solve the problems of poor bearing capacity and vibration reduction effect, and achieve the effects of improving bearing bearing capacity, improving bearing performance deterioration, and improving adaptability to variable working conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the embodiments and drawings, but the present invention is not limited.

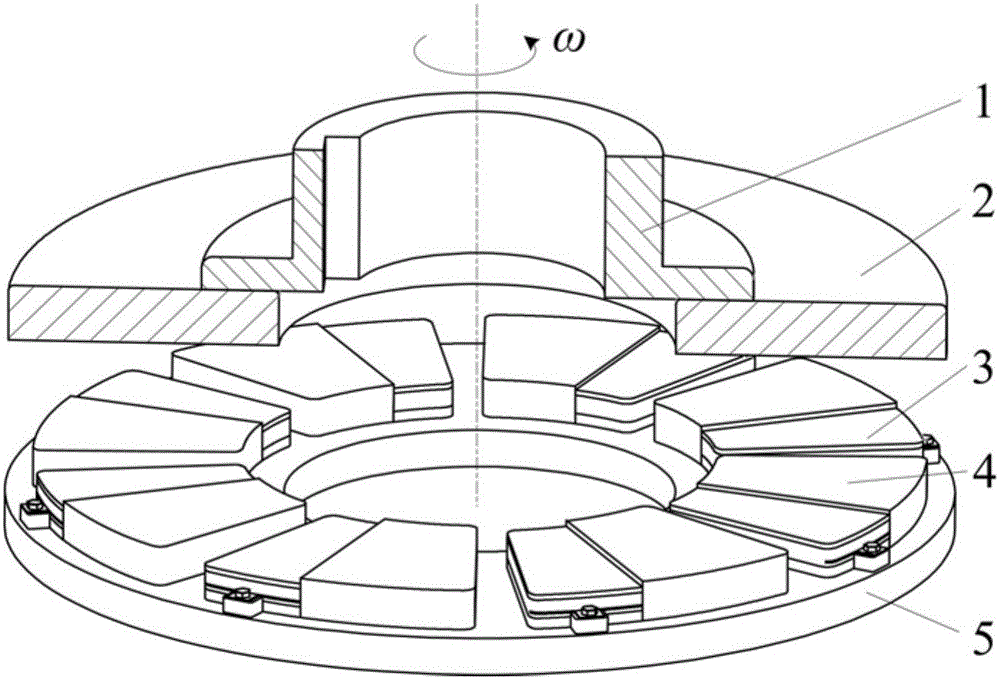

[0030] The invention provides a variable step damping thrust bearing, which has a structure such as figure 1 As shown, it is mainly composed of a pressure head 1, a thrust plate 2, a plurality of movable tile assemblies, a plurality of fixed tiles 4 and a support ring 5 arranged from top to bottom. The thrust plate 2 is connected with the rotating shaft through the indenter 1, and the three are coaxially connected together. A set of movable tile components and a piece of fixed tile form a set of bearing tile components, and multiple sets of bearing tile components jointly bear the total axial load. Seen from the rotation direction of the thrust plate 2, the movable tile assembly of each bearing tile assembly is installed before the fixed tile.

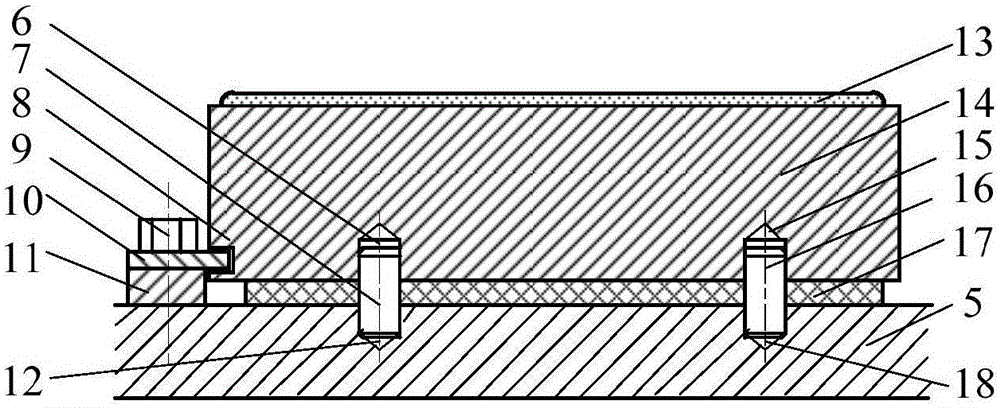

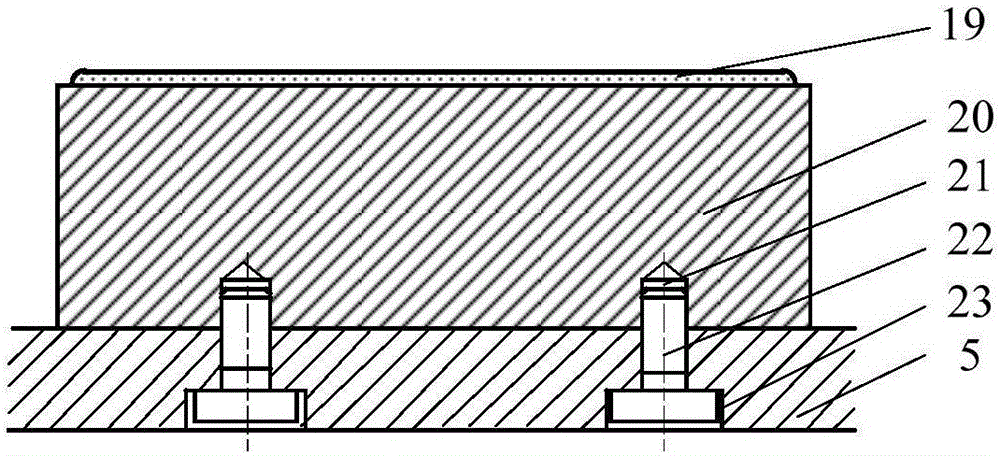

[0031] The structure of the set of movable tile components is as figure 2 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com