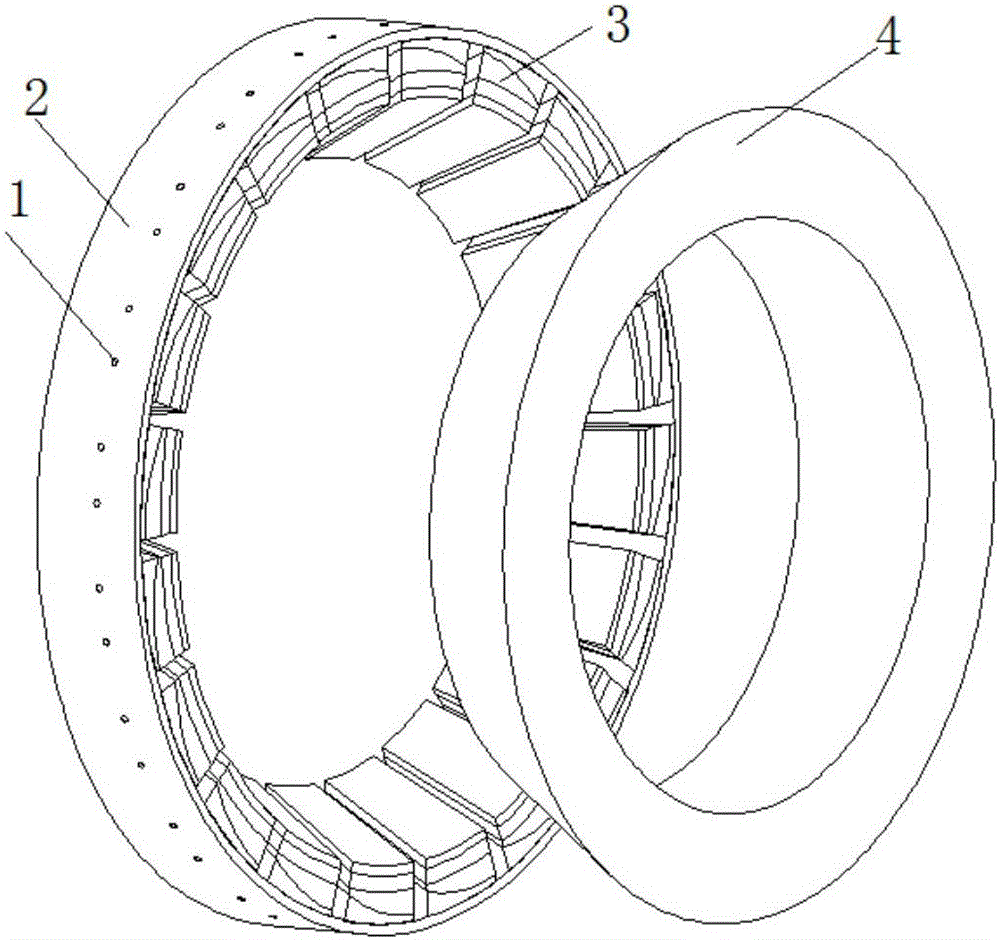

Water-lubricated thrust-radial combined bearing for shaftless propeller

A water-lubricated and propulsion technology, applied in rotary propellers, propulsion components, ship propulsion, etc., can solve the problems of narrow installation space, optimal bearing capacity, poor vibration reduction effect, etc., so as to reduce wear and improve service life. , the effect of eliminating the obstruction of sediment flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

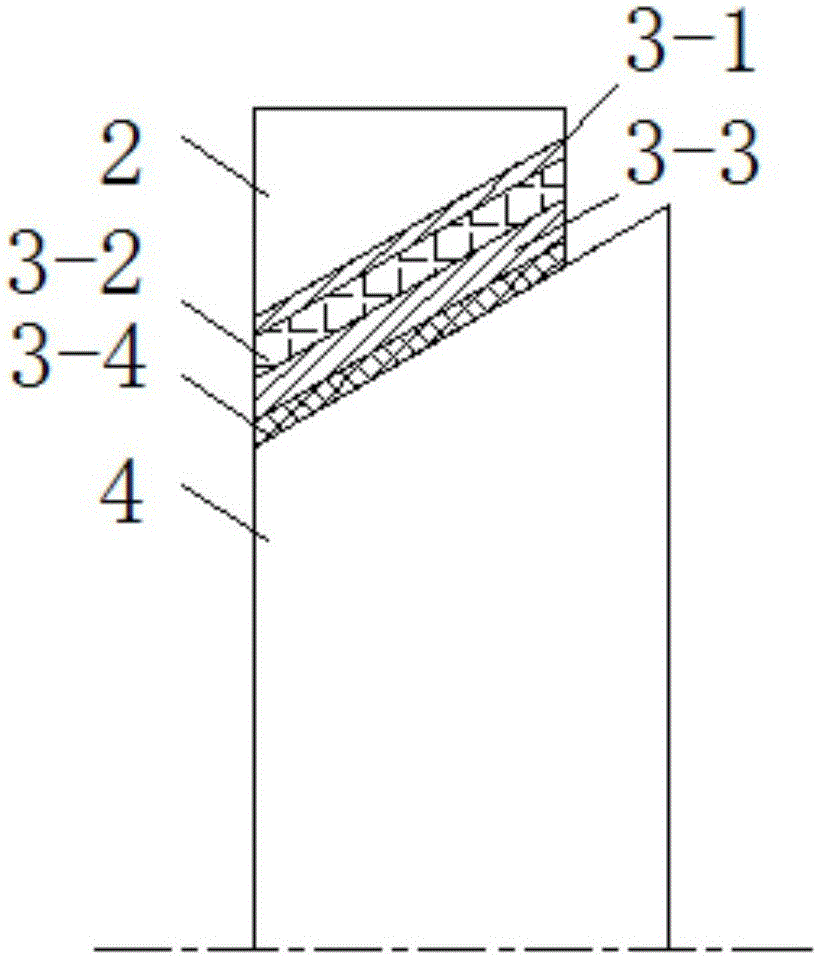

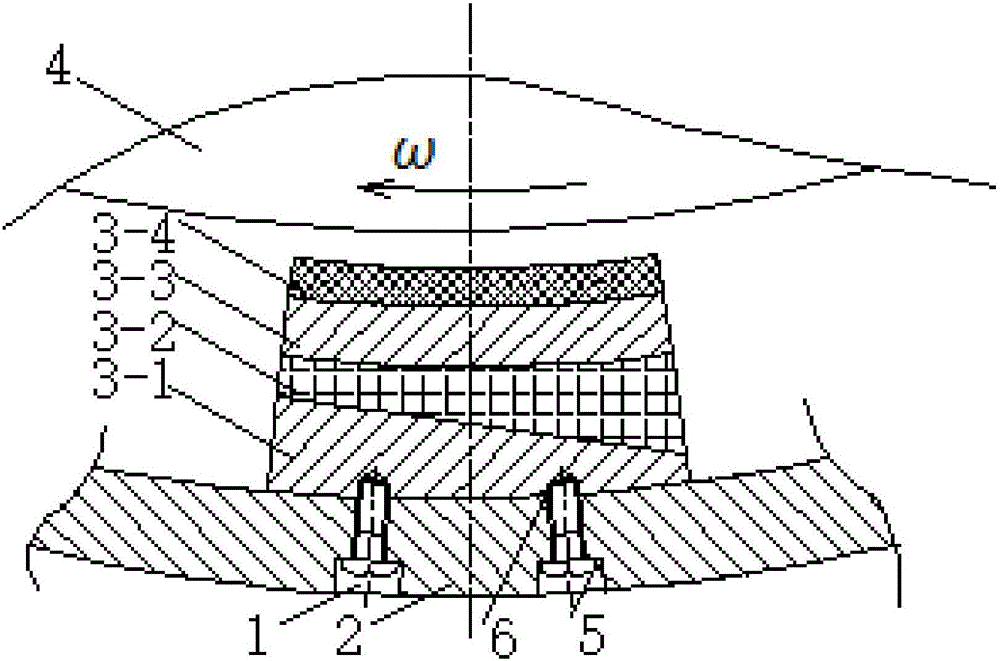

[0040] 1. If image 3 As shown, wherein the lower surface of the rubber layer 3-2 and the upper surface of the lower tile base 3-1 are plane. The space angle formed by the lower surface of the rubber layer 3-2 and the vertical plane passing the bearing axis is not equal to 90°, and the rubber layer 3-2 becomes thinner and thinner along the shaft rotation direction. The specific parameters of the rubber layer can be optimized according to the actual working conditions, and the optimization goal is the maximum bearing capacity.

[0041] 2. If Figure 4 As shown, the lower surface of the rubber layer 3-2 is a circular arc surface, and the two are also tightly connected through the vulcanization process, and the rubber layer 3-2 becomes thinner and thinner along the axis of rotation. The parameters of the arc surface should be optimized according to the actual working conditions, and the optimization goal is the maximum bearing capacity.

[0042] The water-lubricated push-diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com