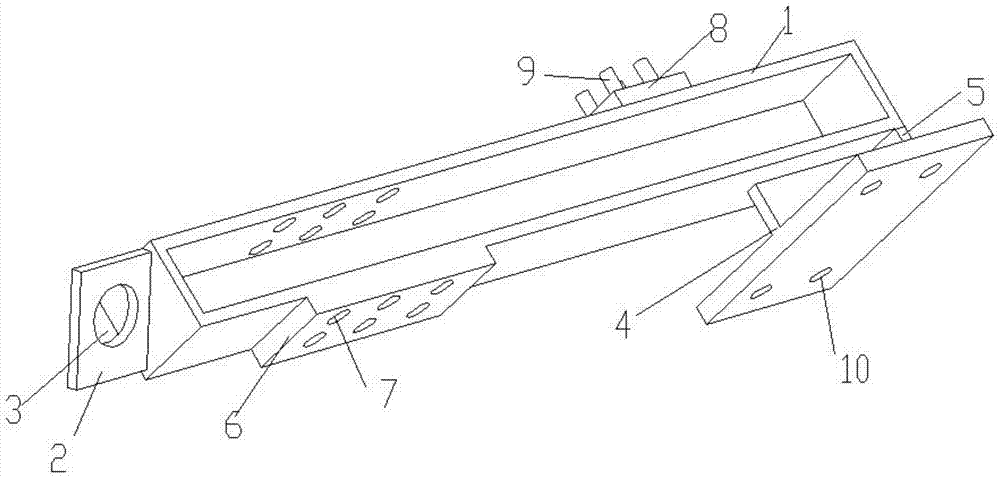

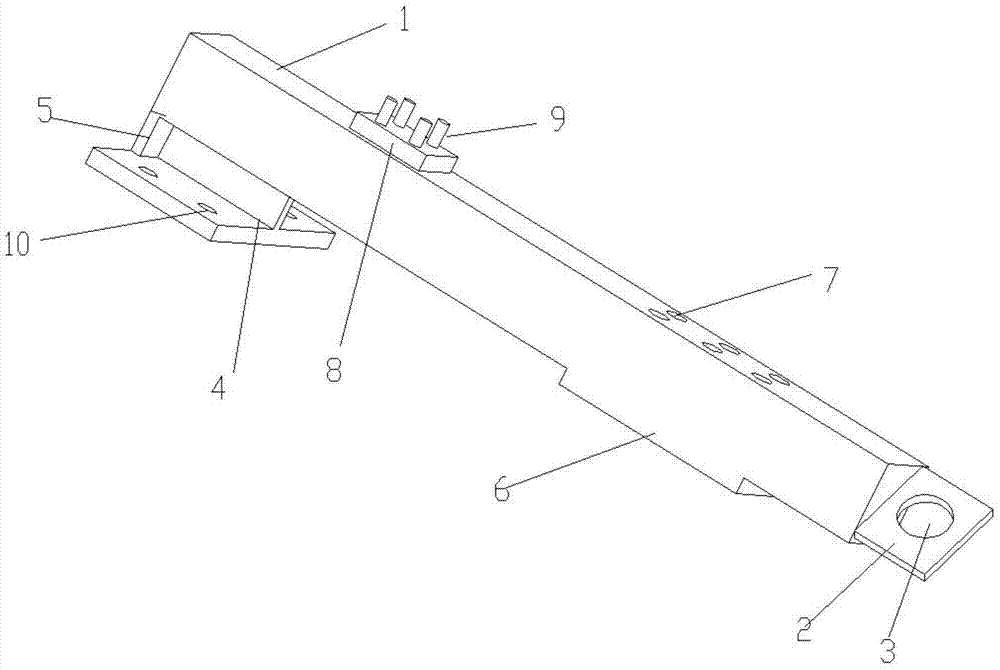

A semiconductor production equipment bracket

A technology for production equipment and semiconductors, applied in the field of brackets, can solve problems such as low assembly efficiency, inability to guarantee assembly quality, and high assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: A support for semiconductor production equipment, including a support body 1 in a rectangular parallelepiped shape, the inside of the support body is hollow, one front of the support body is open, and one end in the length direction of the support body is fixed Cube positioning block 2, the positioning block is provided with a positioning hole 3, the axis line of the positioning hole and the center line of the length direction of the support body are at an angle of 45 degrees, and the lower end surface of the support body is fixed and inverted. T-shaped positioning plate 4, the inverted T-shaped positioning plate is located at the other end of the bracket body in the length direction. The angle between the positioning hole on the positioning block and the bracket body is 45 degrees, which can facilitate assembly and improve assembly efficiency. Through the design of the inverted T-shaped positioning plate, the structure of the bracket is more in line with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com