Large piece processing workshop crane scheduling optimization method

A technology for processing workshops, optimization methods, applied in data processing applications, forecasting, resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

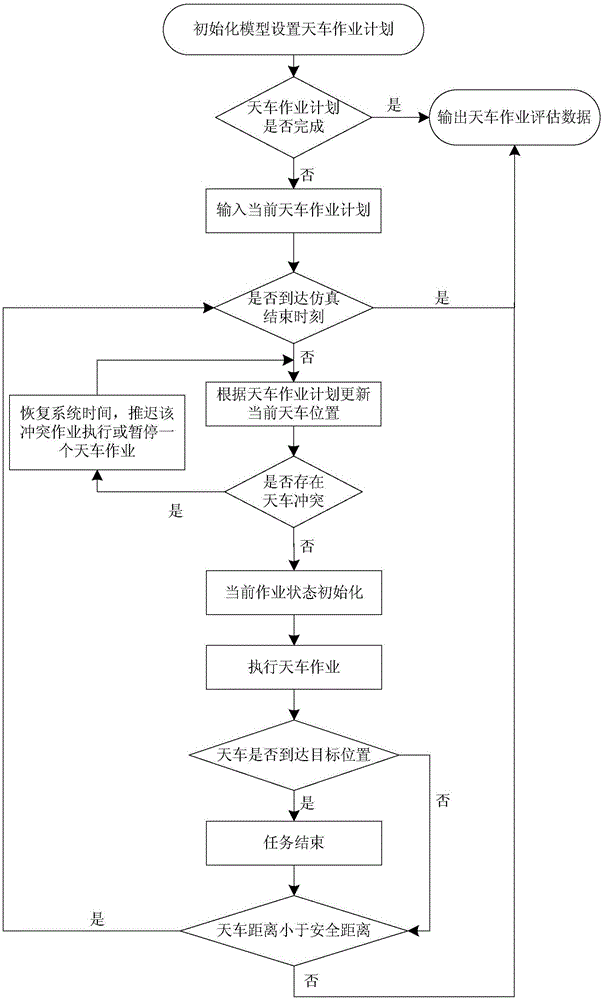

[0064] As shown in the figure, the present invention comprises the following steps:

[0065] 1) Determine the production operation plan, and abstract each task of crane scheduling into a task event;

[0066] 2) Determine the job allocation of the crane workshop and arrange the operation sequence of each crane, and simulate the operation process of the crane according to the positional relationship of the operation intervals of each job task in the plan;

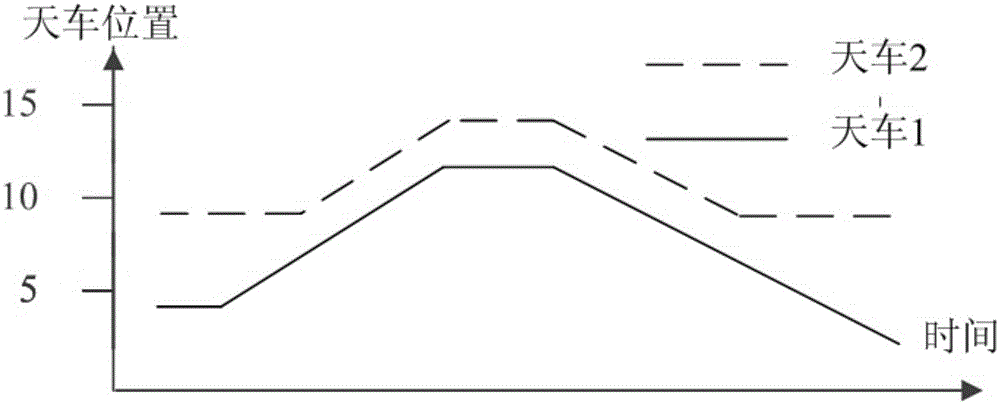

[0067] 3) Characterize the spatial position of the cranes at different times, and judge whether there is a spatial conflict between the cranes;

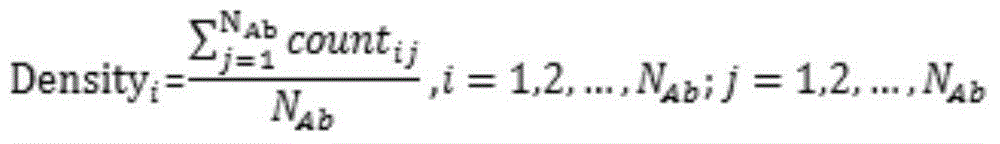

[0068] 4) Evaluate whether the crane scheduling scheme is feasible or optimized through the simulation operation process, and the simulation results provide new feedback values for the scheduling algorithm; introduce the following symbol system:

[0069] C: Crane set, C={1, 2,..., M};

[0070] Ω: Crane operation set, Ω={1, 2, ..., N};

[0071] Ψ: inventory location set, Ψ={1, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com