Nuclear fuel assembly repair detection control system

A technology for detection and control systems and nuclear fuel components, applied in the field of nuclear power generation, can solve problems such as failure to respond in time, damage to nuclear fuel components, and impact on repair efficiency, etc., to achieve the effects of saving manpower, high repair efficiency, and good operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

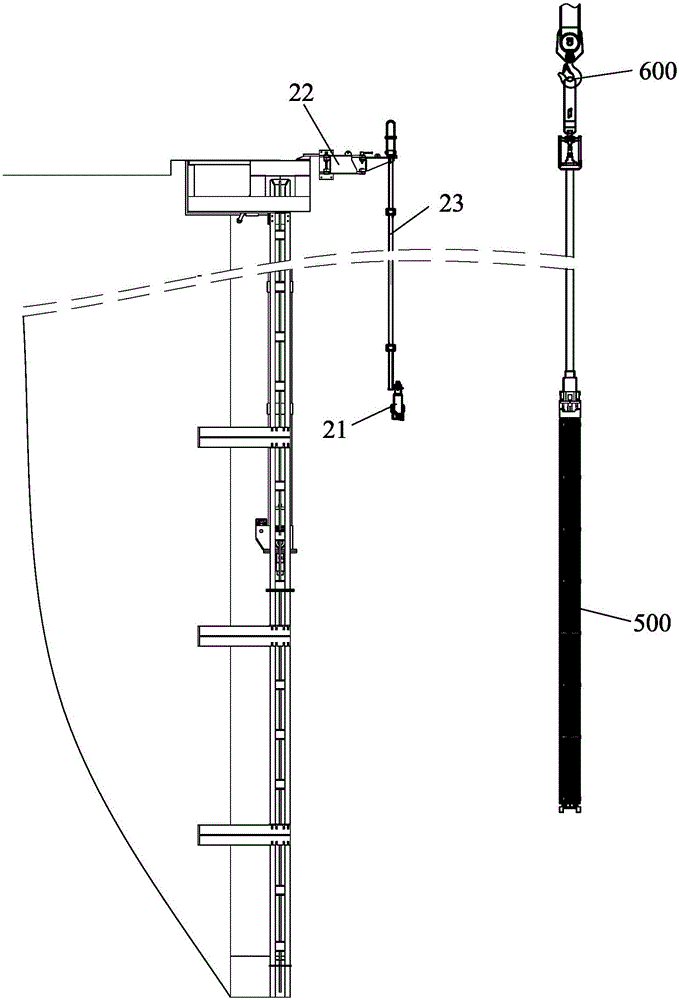

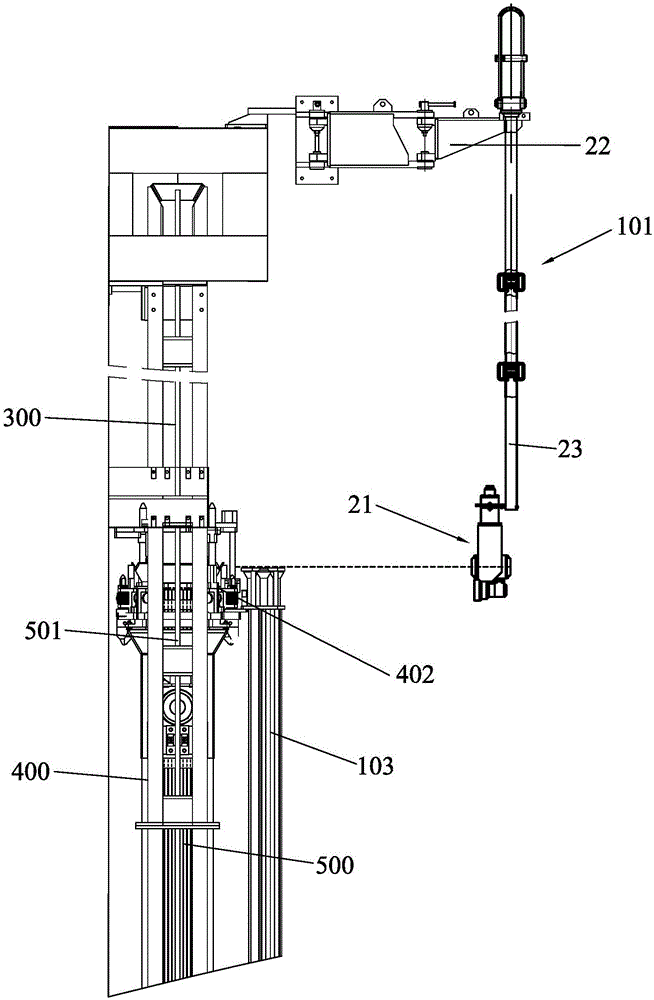

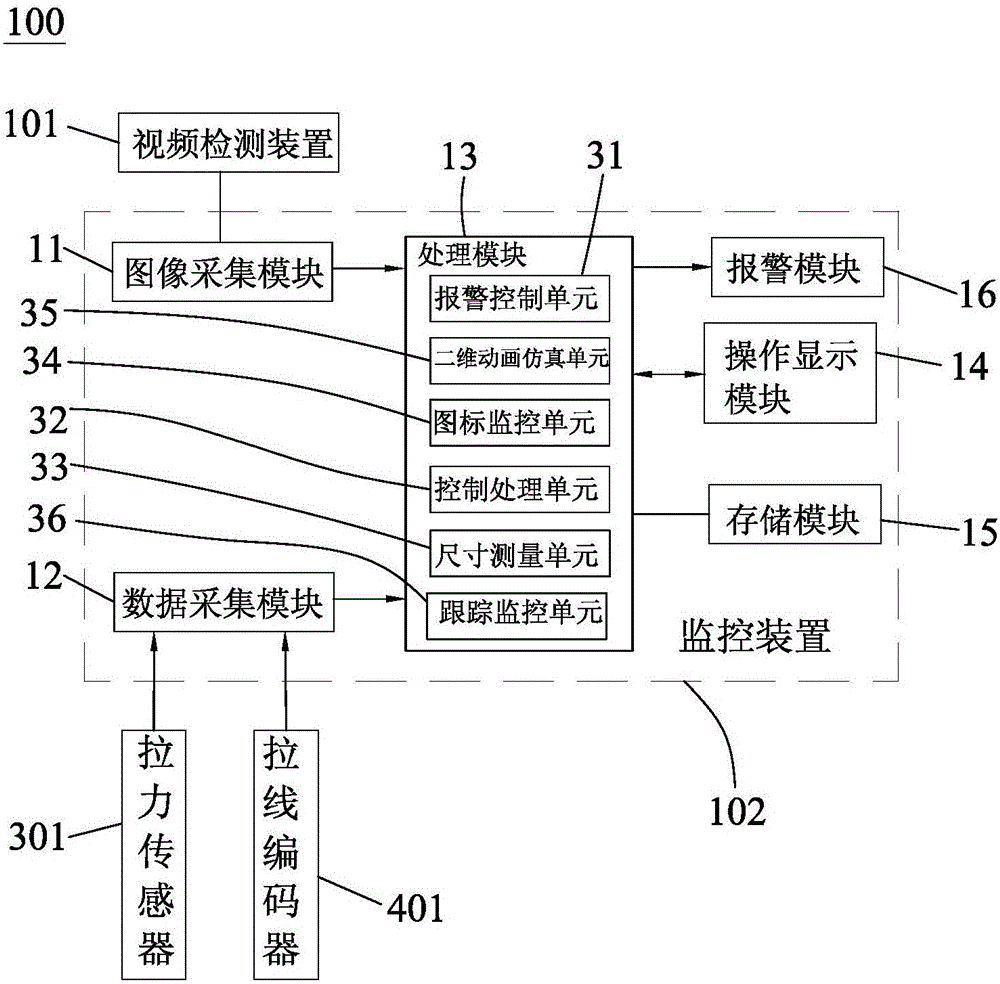

[0040] refer to Figure 1 to Figure 3 , the present invention discloses a nuclear fuel assembly repair detection control system 100, which is used for nuclear fuel assembly video detection and monitoring work for repairing damaged nuclear fuel assemblies, including a video detection device 101 and a monitoring device 102, and the video detection device 101 collects and detects nuclear fuel assemblies Video images of breakage work and repair work on damaged nuclear fuel assemblies. The monitoring device 102 accepts and displays the video images VS collected by the video detection device 101 to perform video detection of nuclear fuel assemblies and real-time monitoring of the rod replacement work of nuclear fuel rods, and the monitoring devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com