Noise-reduction wiring locking device for construction machinery equipment

A technology for construction machinery and locking devices, which is applied to the components, coupling devices, and connections of connecting devices, and can solve problems such as operator inconvenience, safety accidents, and reduced construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

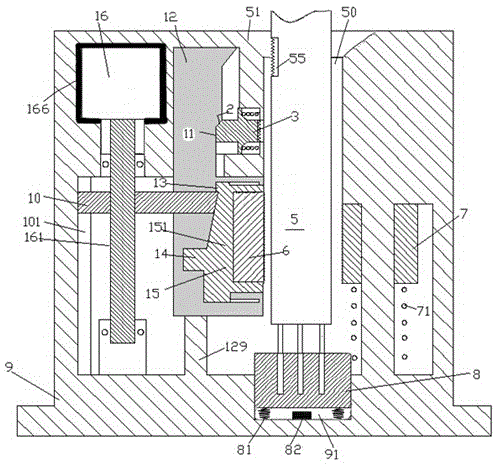

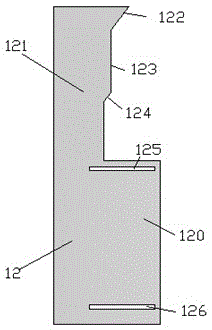

[0009] The following specific examples and attached Figure 1-2 The present invention will be described in detail.

[0010] According to an embodiment, a wiring locking device for construction machinery and equipment that can reduce noise includes a device frame 9 and a drive motor 16 fixed in the device frame 9, and a power supply is arranged in the device frame 9 The wire insertion channel 50 is used for inserting the power cord 5, and the driving motor 16 is power-connected with the screw rod 161 extending downward from the driving motor 16, and the driving wedge 10 is threaded on the screw rod 161. The wedge-shaped surface on the right side of the driving wedge 10 is slidingly matched with the inclined surface in the main body 151 of the locking slider 15 that can slide left and right on the bearing locking slider 12, and the right end of the driving wedge 10 is in contact with the device frame. The guide groove 101 extending up and down in 9 is slidingly fitted, wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com