Driving debugging tool

A technology for debugging tooling and debugging board, applied in the field of mechanical tooling, can solve problems such as meeting the standard and not being able to determine the performance of the optical part well, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

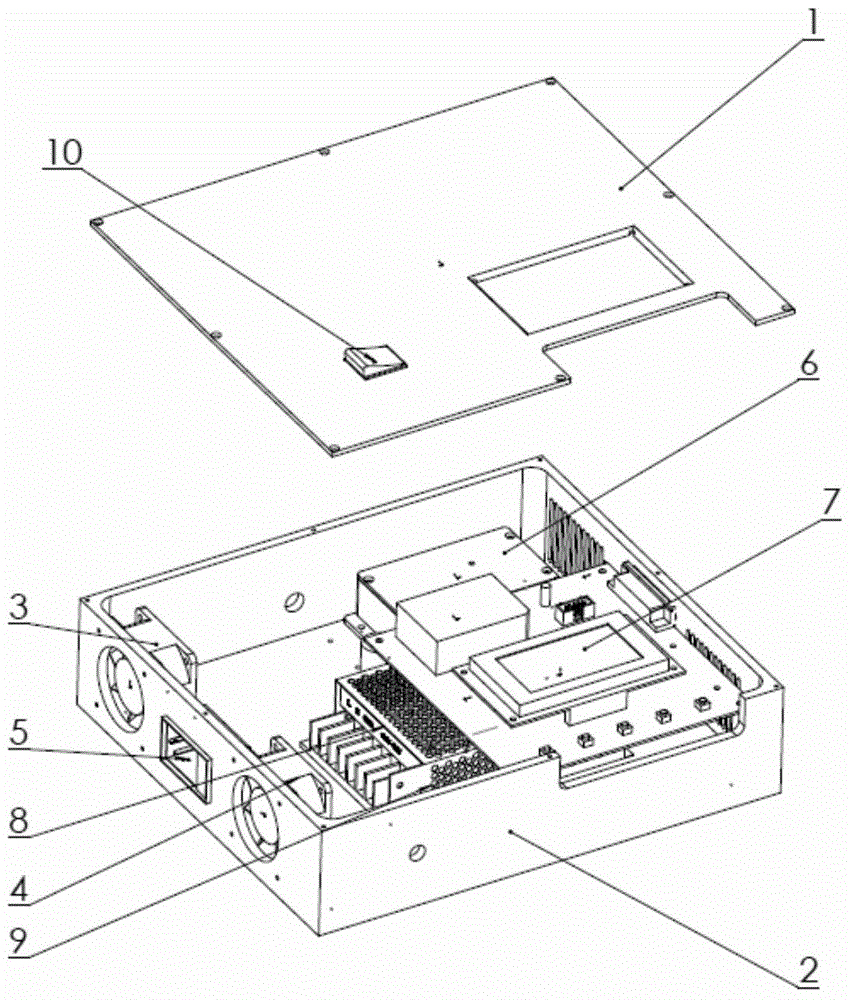

[0015] Such as figure 1 As shown, the present invention is composed of a debugging board 7, a housing 2, a driver I6, a driver II9, two fans (3, 4), a power socket 5, a double-pole double-throw switch 10, a switching power supply 8, and a cover plate 1. It is characterized in that: the cover plate 1 is covered and fixed on the bottom case 2; the power socket 5 is fixed on the bottom case 2 by buckling; two fans (3, 4), driver I6, debugging board 7, switching power supply 8. The drive II 9 is respectively fixed on the bottom case 2; the switching power supply 8 is respectively connected to the two fans (3, 4), the power socket 5, and the debugging board 7 through wires to form a circuit, and the two fans (3, 4) are In parallel connection, driver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com