Rolling type noodle and wrapper maker

A noodle-pressing and rolling-type technology, which is applied in the field of rolling-type noodle dough machines, can solve the problems of shortened service life, time-consuming disassembly and installation, wear and tear, etc., and achieves the effects of saving time, convenient adjustment and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

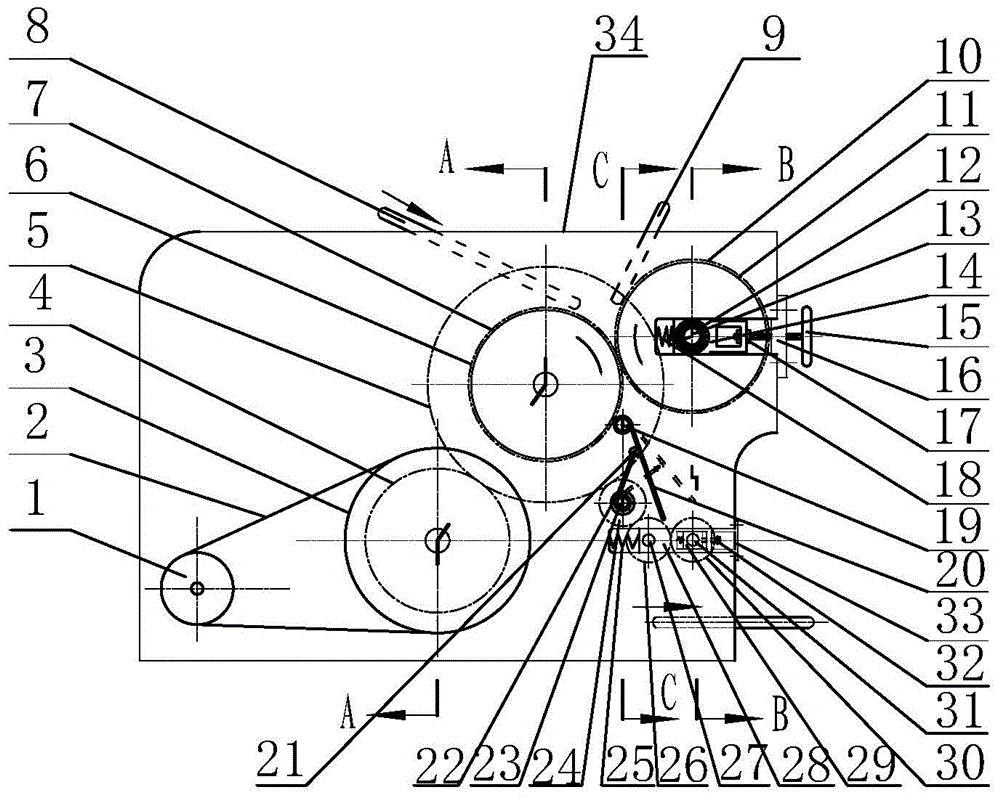

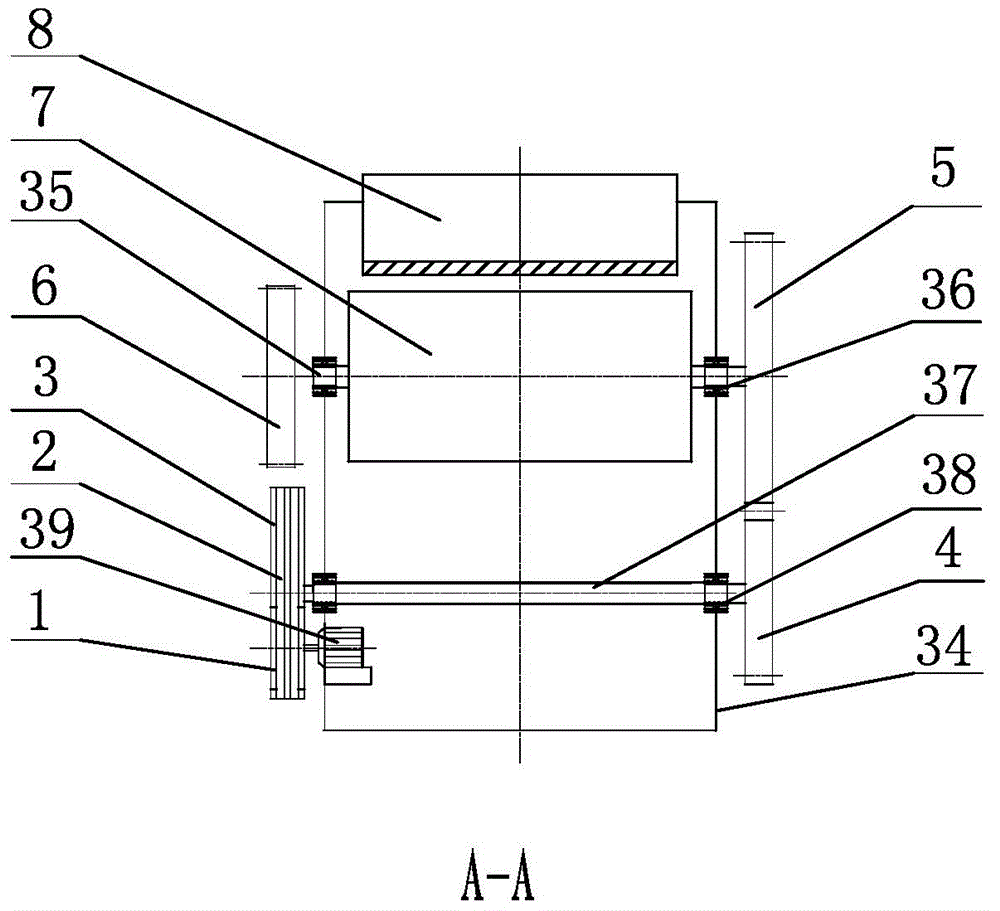

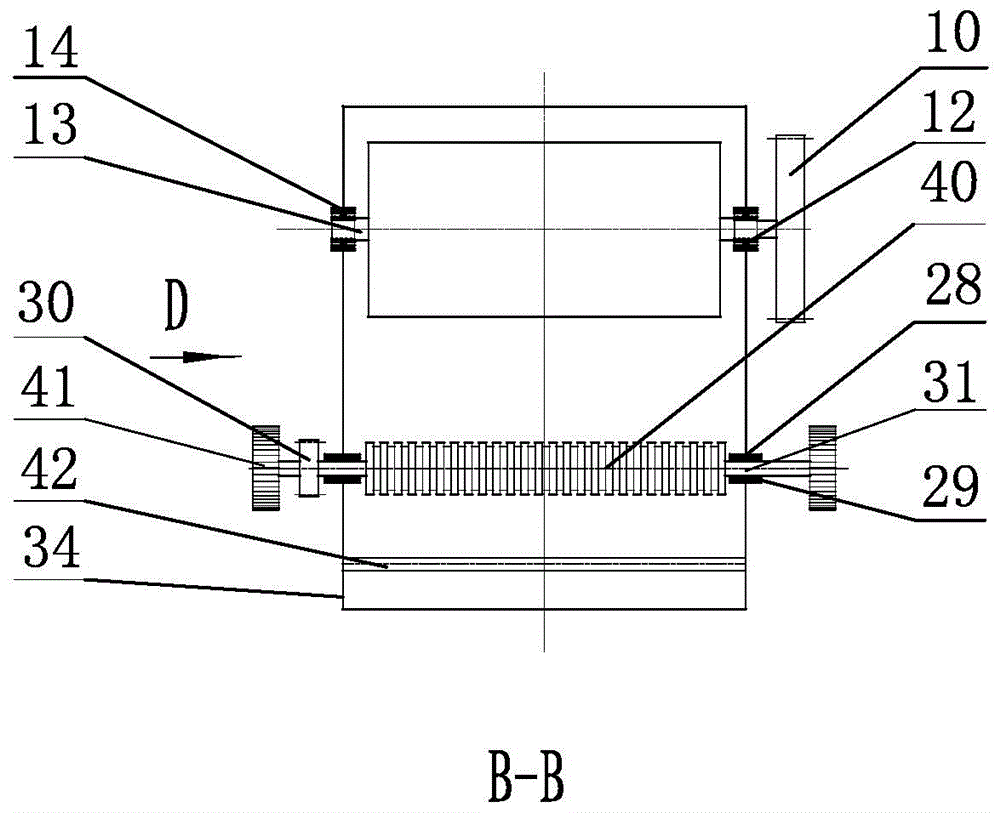

[0021] A kind of rolling type noodle dough machine of the present invention is described in detail below with reference to accompanying drawing of description.

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 Shown, a kind of rolling type noodle dough machine of the present invention comprises frame and the inlet panel that is arranged on the frame, noodle pressing mechanism, noodle pressing mechanism, output panel;

[0023] Described face-pressing mechanism comprises the first face-pressing roller 7 and the second face-pressing roller 11 that rotate around their own axes respectively and are horizontally arranged, and the rotation directions of the first face-pressing roller 7 and the second face-pressing roller 11 are opposite; Between the first noodle-pressing roller and the second noodle-pressing roller is the noodle-pressing working area; the upper end of the noodle-pressing working area is the noodle-in end, and the lower end is the noodle-out end; the noo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com