An automatic fish filleting machine

A fish filleting machine and automatic technology, applied in fish processing, slaughtering, food science, etc., can solve the problems of increasing labor costs, cleaning fish fillets, fish waste, etc., and achieve the effects of improving work efficiency, convenient use, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

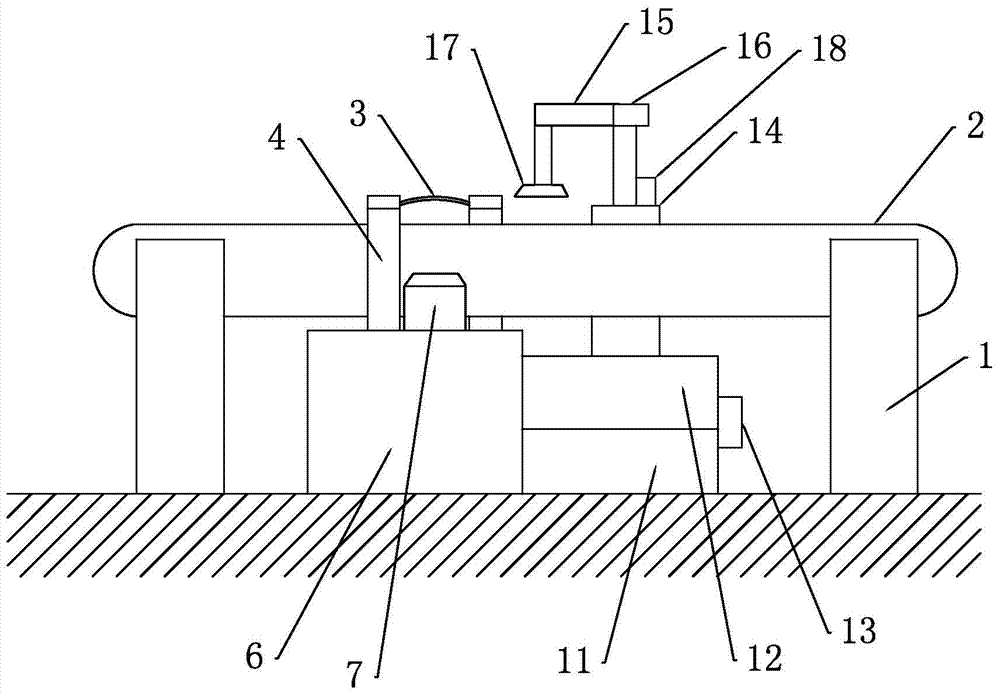

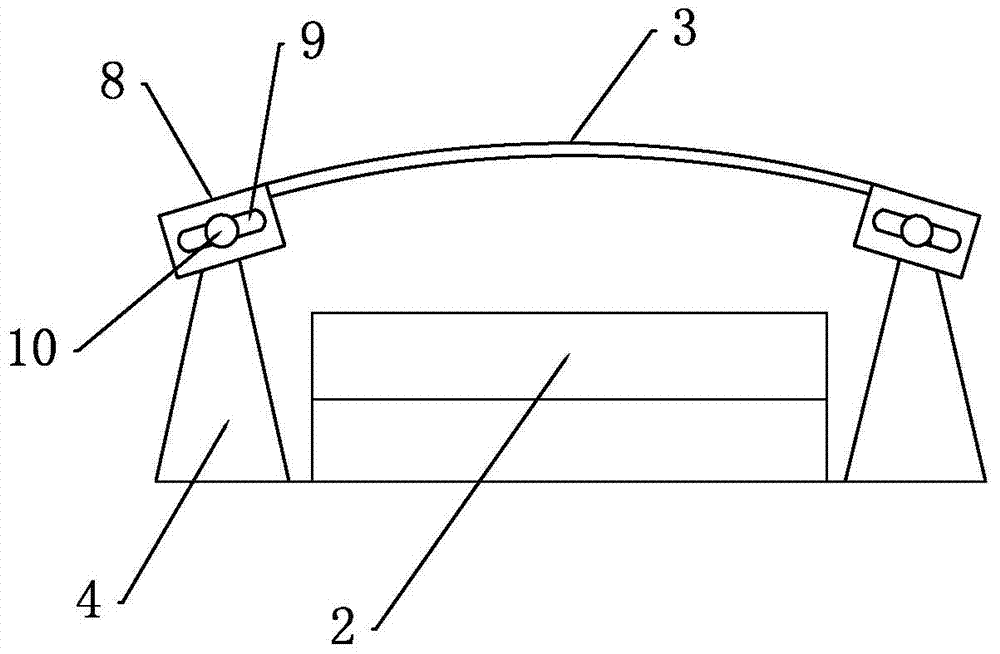

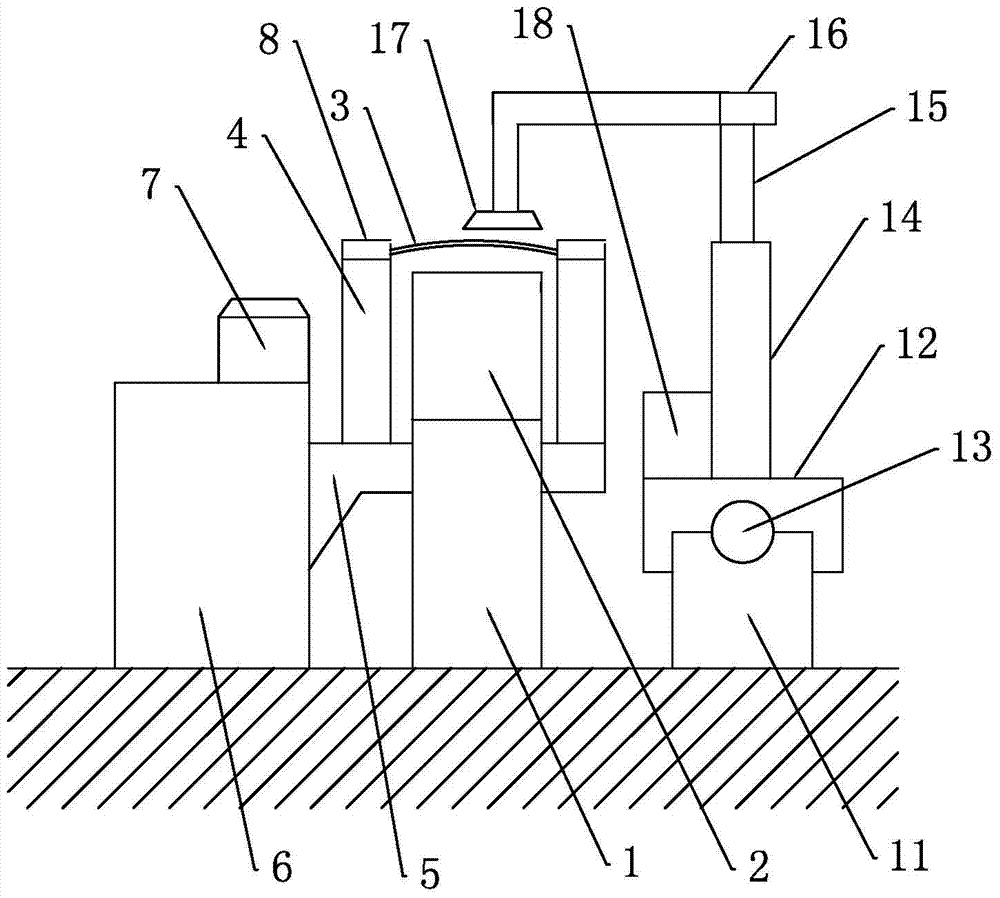

[0022] like Figure 1-3 Shown, a kind of automatic filleting machine comprises a conveyor belt support base 1, is provided with a conveyor belt 2 on the conveyor belt support base 1, and the output shaft of the conveyor belt motor that is arranged on the conveyor belt support base 1 is connected with the driving wheel of the conveyor belt, The top of the conveyor belt 2 is erected with a horizontally arranged fish slicer knife 3 with adjustable radian. The fish slicer knife 3 is arranged obliquely relative to the width direction of the conveyor belt 2, and the two ends of the fish slicer knife 3 are movable and fixed on two support columns 4 respectively , the two support columns 4 are respectively mounted on a sliding table 5 arranged below the conveyor belt 2, the outer end of the sliding table 5 is installed on the sliding table seat 6 through the first ball screw, and a driving first drive is arranged on the top of the sliding table seat 6 The slide table motor 7 of ball s...

Embodiment 2

[0027] The difference from Example 1 is that, as Figure 4 As shown, the fish-pressing stripping device includes a fish-pressing support seat 19 arranged on one side of the conveyor belt support seat 1, and a metal fish-pressing conveyor belt 20 arranged above the conveyor belt along the length direction of the conveyor belt is installed on the fish-pressing support seat 19, an output shaft of the fish conveyor belt motor that is arranged on the fish pressure support seat 19 is connected with the driving wheel of the fish conveyor belt 20, and a peeling knife support is provided on the fish pressure support seat 19 at one end of the running direction away from the conveyor belt 2 21. A stripping knife 22 is arranged on the stripping knife support 21, and the blade of the stripping knife 22 abuts against the fish-pressing conveyor belt 20; a refrigerator 23 is also provided on one side of the fish-pressing support seat 19, and the annular cold air jet of the refrigerator 23 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com